Turbulent/fast fluidized bed reactor with baffle for maximizing low-carbon olefin yield

A fluidized bed reactor and low-carbon olefin technology, which is applied in ethylene production, catalytic cracking, hydrocarbon oil treatment products, etc., can solve the problems of large amounts of methane, increased production costs, and low yield of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

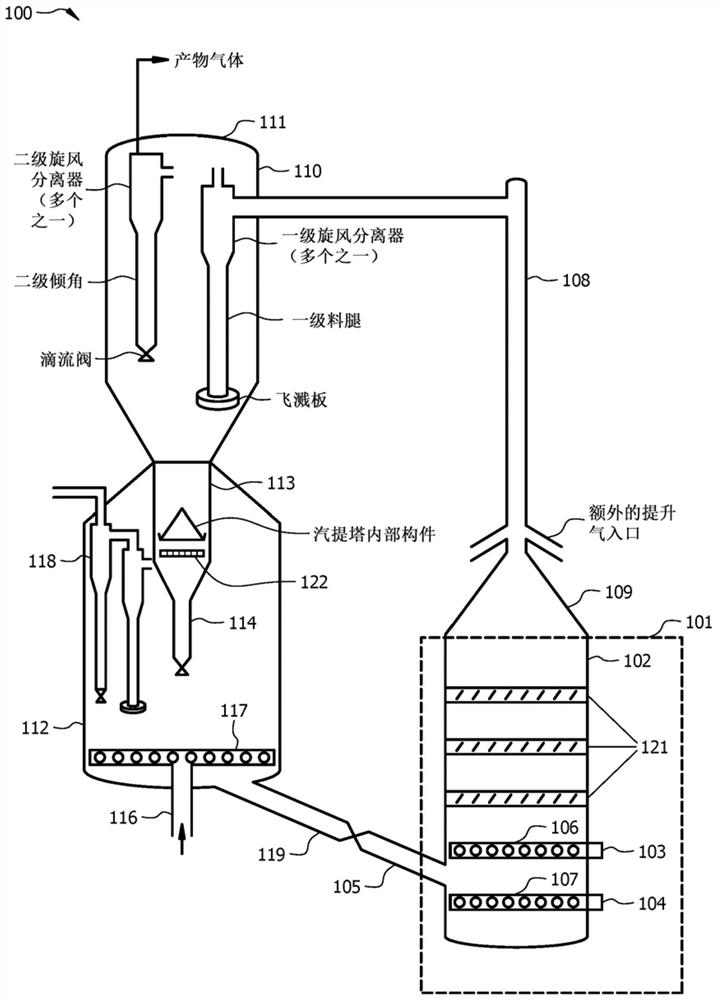

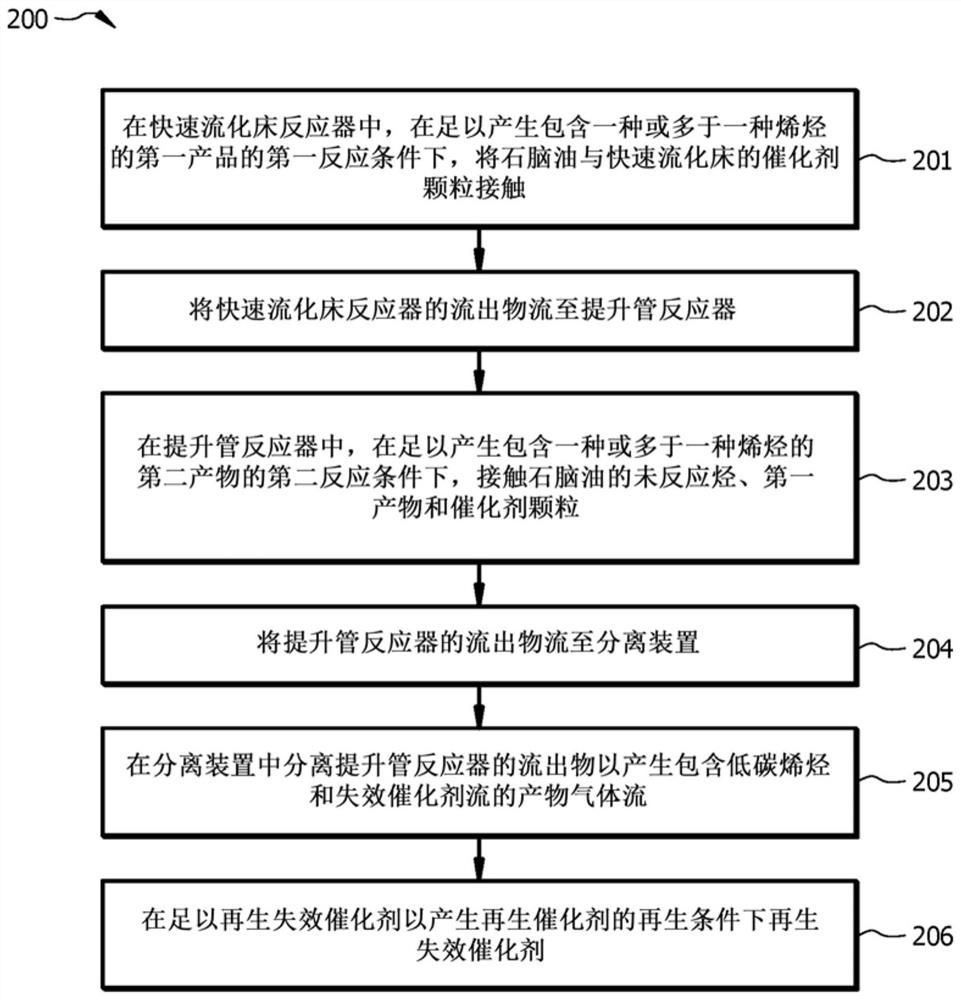

[0050] (Fast Fluidized Bed Pilot Plant and Riser Reactor for Light Olefin Production)

[0051] The pilot plant of the above reaction device is used to produce light olefins through catalytic cracking of naphtha. The reaction involves a fast fluidized bed reactor (FFBR) connected to a riser reactor. Fast fluidized bed reactors include horizontal baffles therein to minimize back mixing in the reaction unit. The naphtha used in the pilot plant experiments included 22% to 24% by weight of normal paraffins, 27% to 30% by weight of isoparaffins, 32% to 35% by weight of naphthenes, 11% to 13% by weight aromatics, less than 0.5% by weight aromatics and less than 8% by weight other components. The reaction conditions during the experimental run of the pilot plant included a reaction temperature of 700°C, a regeneration temperature of 710°C, a contact time of 1.03 seconds to 1.16 seconds, and a catalyst loading of 1500 g. The yield results of the products obtained in the pilot plant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com