Preparation method for cobalt-based Fischer-Tropsch synthesis catalyst

A technology for the synthesis and catalyst of cobalt-based Fischer-Tropsch synthesis, which is applied in the field of preparation of cobalt-based Fischer-Tropsch synthesis catalysts, which can solve problems such as application limitations of cobalt-based Fischer-Tropsch synthesis catalysts, affecting catalyst life, and catalyst deactivation, and achieves suppression of hydrothermal reactions and low cost , the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

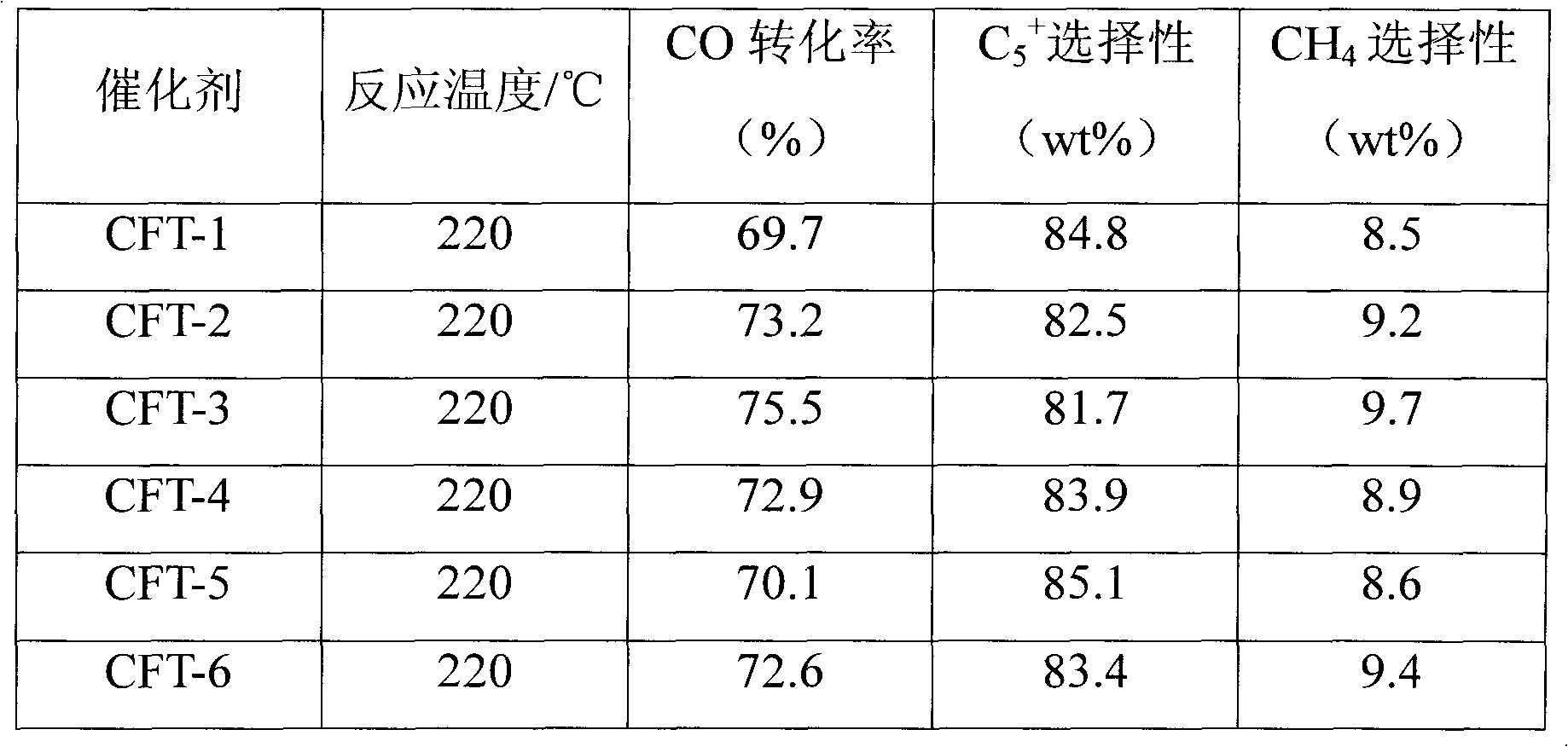

example 1

[0016] Deactivated CoZr / SiO 2 The catalyst is 50g, and the elemental analysis results show that the zirconium content is 2.85wt%, and the cobalt content is 18.6wt%. First, n-octane and catalyst are used for extraction and separation for 1-2 times, and then ethanol is used for extraction and separation for 1-3 times. The extraction time is 5 hours, and then drying and roasting are carried out. The drying temperature is 90°C, the drying time is 8h, and the calcination is at 350°C for 4 hours. Finally weigh 20g, impregnate according to the amount of 5wt% Co added, weigh 4.94g of cobalt nitrate hexahydrate solution in 27.06g of distilled water, add it to the deactivated catalyst after it is completely dissolved, stir until uniform, age for 5h, and dry at 50°C 24 hours, and baked at 280°C for 10 hours. The resulting catalyst was designated CFT-1.

[0017] Catalyst evaluation test In a high-pressure continuous stirred tank reactor, paraffin was used as a solvent, and pure hydroge...

example 2

[0019] Deactivated CoZr / SiO 2 The catalyst is 50g, and the elemental analysis results show that the zirconium content is 2.85wt%, and the cobalt content is 18.6wt%. First, use n-octane and catalyst to extract and separate 1-2 times, and then use ethanol to extract and separate 2-3 times at room temperature. The extraction time is 2 hours, and the extraction temperature is controlled at 40-50 ° C, and then dried and separated. Roasting. The drying temperature is 80°C, and the drying time is 10 hours. Baking Baking was carried out at 300° C. for 8 hours. Then weigh 20g, according to the amount of impregnating 7.5wt% Co, weigh 7.41g of cobalt nitrate hexahydrate solution in 17.18g of distilled water, add it to the above spent catalyst and stir until it is completely dissolved, age for 20h, and dry at 150°C for 8 hours , baked at 600°C for 2 hours. The obtained catalyst is denoted as CFT-2, and the experimental conditions for catalyst activity evaluation are the same as those ...

example 3

[0021] Deactivated CoZr / SiO 2 The catalyst is 50g, and the elemental analysis results show that the zirconium content is 2.85wt%, and the cobalt content is 18.6wt%. First, use n-octane and catalyst to mix and extract and separate 2-3 times under stirring conditions, then use ethanol to extract and separate 1-3 times, the extraction time is 8 hours, the extraction temperature is controlled at 40-50 °C, and then Dry and roast. The drying temperature is 100°C, and the drying time is 5 hours. Baking Baking was performed at 400° C. for 2 hours. Finally, 20g was weighed, and according to the amount of impregnating 10wt% Co, 9.88g of cobalt nitrate hexahydrate solution was weighed in 22.12g of distilled water, and after it was completely dissolved, it was added to the spent catalyst and stirred until uniform, aged for 10 hours, and dried at 80°C for 6 hours. Baking at 400°C for 6 hours. The obtained catalyst is denoted as CFT-3, and the experimental conditions for catalyst activi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com