Method for reducing cobalt-base Fischer Tropsch synthesis catalyst

A technology for the synthesis of catalysts and catalysts, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of increased water pressure in the system, unfavorable industrial operations, and difficulty in taking away, and achieve initial activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

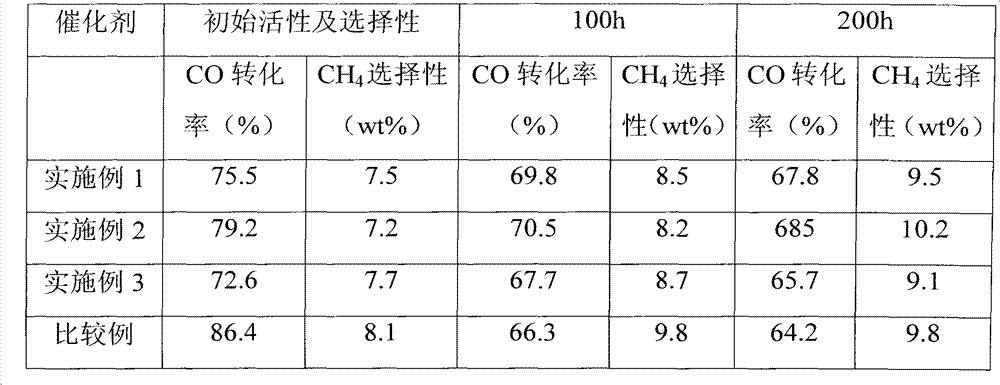

Examples

example 1

[0020] Loaded Cobalt-based Fischer-Tropsch Synthesis Catalyst 20%Co0.8%Pt3%Zr / SiO 2 (Wt.), under normal pressure, pass inert gas, space velocity is 500h -1 , completely replace the air in the reduction system with an inert gas at normal temperature and pressure, then maintain the pressure of the reduction system at 0.1 MPa, raise the temperature from room temperature to 300 °C at 1 °C / min, dry for 12 hours, and then cool down to 120 °C. switch concentration to 5% H 2 Mixed gas with inert gas, the space velocity is 2000h -1 , from 120°C to 300°C at 1°C / min, and then gradually increase the H in the mixture 2 The concentration is above 90%, reduced for 24 hours, and then cooled to 120°C. Introduce hydrogen containing 2% water vapor with a space velocity of 500h -1 , the temperature was raised from 120°C to 200°C at 1°C / min, maintained for 12 hours, and then lowered to 120°C. switch concentration to 5% H 2 Mixed gas with inert gas, the space velocity is 2000h -1 , from 120°...

example 2

[0023] Loaded Cobalt-based Fischer-Tropsch Synthesis Catalyst 20%Co1%Ni3%Zr / TiO 2 (Wt.), under normal pressure, pass inert gas, space velocity is 1500h -1 , use inert gas to completely replace the air in the reduction system at normal temperature and pressure, then increase the pressure of the reduction system to 1.0MPa, raise the temperature from room temperature to 400°C at 3°C / min, dry for 8 hours, and then cool down to 120°C . switch concentration to 5% H 2 Mixed gas with inert gas, the space velocity is 4000h -1 , from 120°C to 400°C at 3°C / min, and then gradually increase the H in the mixture 2 The concentration is above 90%, reduced for 8 hours, and then lowered to 120°C. Introduce hydrogen containing 4% methanol vapor at a space velocity of 1500h -1 , the temperature was raised from room temperature to 250°C at 3°C / min, maintained for 8 hours, and then cooled to 120°C. switch concentration to 5% H 2 Mixed gas with inert gas, space velocity 4000h -1 , from 120°C...

example 3

[0026] Loaded cobalt-based Fischer-Tropsch synthesis catalyst 20%Co0.05%Ru3%Zr / Al2 o 3 (Wt.), under normal pressure, pass inert gas, space velocity is 1000h -1 , use an inert gas to completely replace the air in the reduction system at normal temperature and pressure, then increase the pressure of the reduction system to 0.5MPa, raise the temperature from room temperature to 350°C at 2°C / min, dry for 10 hours, and then cool down to 120°C . switch concentration to 5% H 2 Mixed gas with inert gas, the space velocity is 3000h -1 , from 120°C to 350°C at 2°C / min, then gradually increase the H in the mixture 2 The concentration is above 90%, reduced for 16 hours, and then cooled down to 120°C. Introduce hydrogen containing 3% ethanol vapor at a space velocity of 1000h -1 , the temperature was raised from room temperature to 220°C at 2°C / min, maintained for 10 hours, and then cooled to 120°C. switch concentration to 5% H 2 Mixed gas with inert gas, the space velocity is 3000h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com