A kind of nickel-based selective hydrogenation catalyst initial activation hydrothermal passivation method

A hydrogenation catalyst and selective technology, which can be used in catalyst activation/preparation, selective hydrorefining, chemical instruments and methods, etc., can solve the problems of long start-up period and impact on stable performance, and achieve a shortened start-up period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

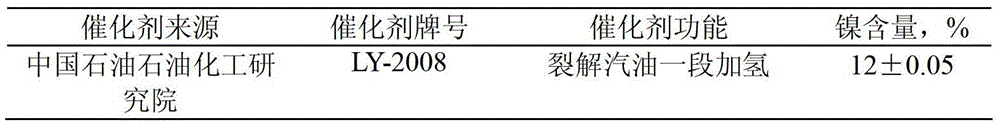

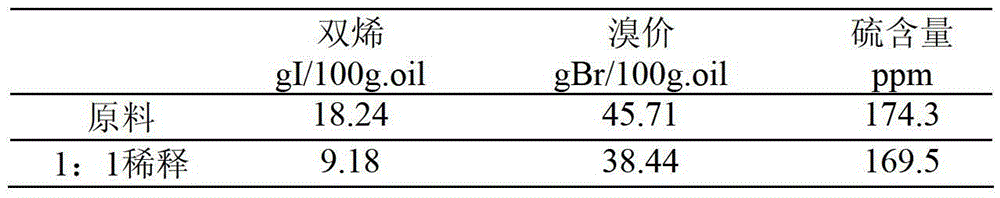

[0021] Raw materials: Lanzhou Petrochemical C 6 -C 7 Distillation pyrolysis gasoline is used as a raw material, and the properties of the raw material are shown in Table 1:

[0022] Table 1 Raw material properties

[0023]

[0024] Catalyst reduction treatment

[0025] On a 100ml fixed-bed reactor, the catalyst loading amount is 100ml (mass 76g), and the catalyst reduction process is completed according to the following process conditions.

[0026] (1) Reduction pressure 0.5MPa;

[0027] (2) The amount of reduced hydrogen is 800 times the volume of the catalyst;

[0028] (3) Reduction process: raise the bed temperature to 150°C at a heating rate of 50°C / h and keep the temperature constant for 4 hours; raise the bed temperature to 250°C at a heating rate of 30°C / h and keep the temperature constant for 8 hours; Raise the bed temperature to 370°C at a heating rate of 30°C / h, and keep the temperature constant for 8 hours; raise the bed temperature to 430°C at a heating rate ...

Embodiment 2

[0044] The catalyst reduction process was carried out according to Example 1. The restoration conditions are as follows:

[0045] 1) Reducing pressure. 3.5MPa;

[0046] 2) The amount of hydrogen to be reduced is 550 times the volume of the catalyst;

[0047] 3) Reduction process: raise the bed temperature to 130°C at a heating rate of 20°C / h, and keep the temperature constant for 6 hours;

[0048] Raise the bed temperature to 230°C at a heating rate of 40°C / h and keep the temperature constant for 5 hours; raise the bed temperature to 350°C at a heating rate of 20°C / h and keep the temperature constant for 5 hours; Raise the bed temperature to 460°C, keep the temperature constant for 5 hours, and lower the bed temperature below 40°C to complete the reduction.

[0049] After the reduced catalyst is discharged from the reactor, the initial activity of the catalyst is deactivated in the moving bed, the temperature of the bed is raised to 380°C, and the water vapor temperature is...

Embodiment 3

[0058] The catalyst reduction process and process conditions were carried out according to Example 1.

[0059] The passivation treatment conditions are as follows:

[0060] (1) The steam treatment temperature is 470°C;

[0061] (2) The steam treatment time is 1 hour;

[0062] (3) The water vapor consumption per hour is 152g / h.

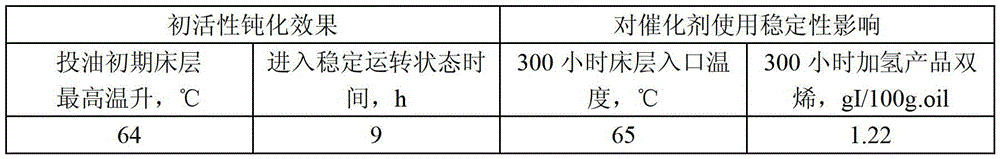

[0063] Table 4 catalyst passivation effect

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com