Spherical magnesium chloride-supported late-transition non-metallocene catalyst and preparation method thereof

A transition metal and magnesium chloride technology, which is applied in the field of spherical magnesium chloride-supported non-metallocene transition metal catalysts and its preparation, can solve the problems of high methylalumoxane dosage, low polymerization molecular weight, and polymer stickiness, etc. Polymerization activity life, simple preparation method, effect of improving polymerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention relates to a kind of supported type non-metallocene post-transition metal catalyst and its preparation method. The main components of the catalyst include spherical magnesium chloride, non-metallocene post-transition metal complexes and aluminum reagents. The preparation process comprises the following steps: making spherical magnesium chloride The alcoholate is contacted with the aluminum reagent for reaction, then suction filtered, washed, and dried; the step of obtaining the spherical magnesium chloride carrier treated with the aluminum reagent; making the solution of the spherical magnesium chloride carrier treated with the above aluminum reagent and a non-aluminocene transition metal complex The step of contacting; and the step of washing, filtering and drying the above-mentioned system to obtain the spherical magnesium chloride-supported non-metallocene late transition metal catalyst.

[0028]According to the present invention, the term "non-m...

Embodiment 1

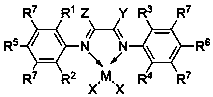

[0103] The magnesium chloride ethanolate (MgCl2•2EtOH) is used for the spherical magnesium chloride, triethylaluminum is used for the aluminum reagent, hexane is used as the solvent for the dispersed spherical magnesium chloride and the aluminum reagent, and the compound with the structure 1a is used for the non-procene transition metal complex. The molar ratio of spherical magnesium chloride in terms of Mg element to triethylaluminum in terms of Al element is 1:3.0, and the molar ratio of magnesium chloride to non-cene transition metal complex is 1:0.15.

[0104]

[0105] 1a

[0106] Take by weighing 10g spherical magnesium chloride, disperse in solvent hexane (accounting for half of the total amount) at normal temperature, add the hexane solution of aluminum reagent dropwise in the dispersion system of spherical magnesium chloride at normal temperature, the dropping time is 30 minutes, drop After the addition was complete, it was stirred at 60°C for 2 hours. Filter and w...

Embodiment 2

[0110] Basically the same as Example 1, but with the following changes:

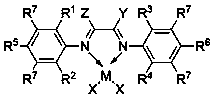

[0111] 1b is used for the non-procene late transition metal complexes.

[0112]

[0113] 1b

[0114] Disperse spherical magnesium chloride was changed to toluene as a solvent. The solvent of the transition metal complex was changed from ethylbenzene to non-azocene.

[0115] Wherein the proportioning is, the proportioning of described spherical magnesium chloride and dispersing solvent in terms of Mg element is 1mol: 1000mL; the molar ratio of spherical magnesium chloride and aluminum reagent is 1: 2.0; The ratio is 1:0.1.

[0116] Supported non-metallocene catalysts are designated CAT-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com