Production technology of electrostatic flocking latex glove

A technology of electrostatic flocking and latex gloves, applied in the direction of coating, etc., can solve problems such as scattered and uneven flocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

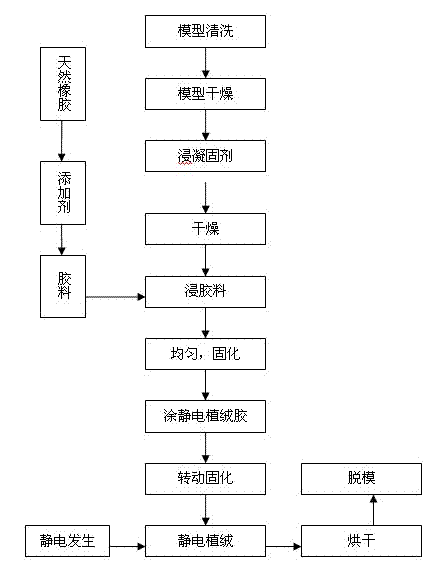

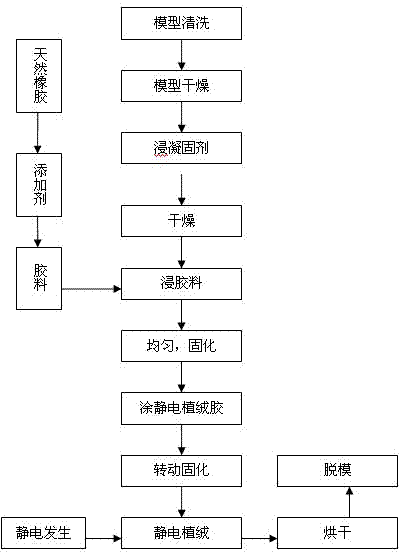

Image

Examples

example

[0015] Example: use cleaning equipment to clean the ceramic hand model with acid and alkali and water, dry it, soak it in a coagulant, and dry it; add additives to natural rubber and process it into a usable latex liquid, and then immerse the ceramic hand model in the latex liquid to form a Layer latex film, wait for it to be uniformly cured; configure electrostatic flocking glue, evenly coat a layer of electrostatic flocking glue on the surface of the latex film, and rotate uniformly; use flocking method for electrostatic flocking, the electrostatic high voltage is 80kV, and the flocking speed The flocking pole distance is 1.5m / min, the flocking pole distance is 350mm; the distance between the fluff conveyor belt and the high-voltage electrode is 50mm, and the flocking time is 15s; use a dust collector to remove dust, dry, and demould.

[0016] The wool flocked by wet electrostatic flocking technology has the same direction and is vertical, it is not easy to take off the wool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com