Water-channel water distribution-type water-distributing system for hydrolysis-acidification pool in industrial waste water treatment

A technology for hydrolyzing acidification ponds and industrial wastewater, applied in anaerobic digestion and treatment, etc., can solve the problems of high initial investment and later operation and maintenance investment, heavy equipment, high price, etc., to strengthen water conservancy distribution and water conservancy mixing, and overcome maintenance Difficulty, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

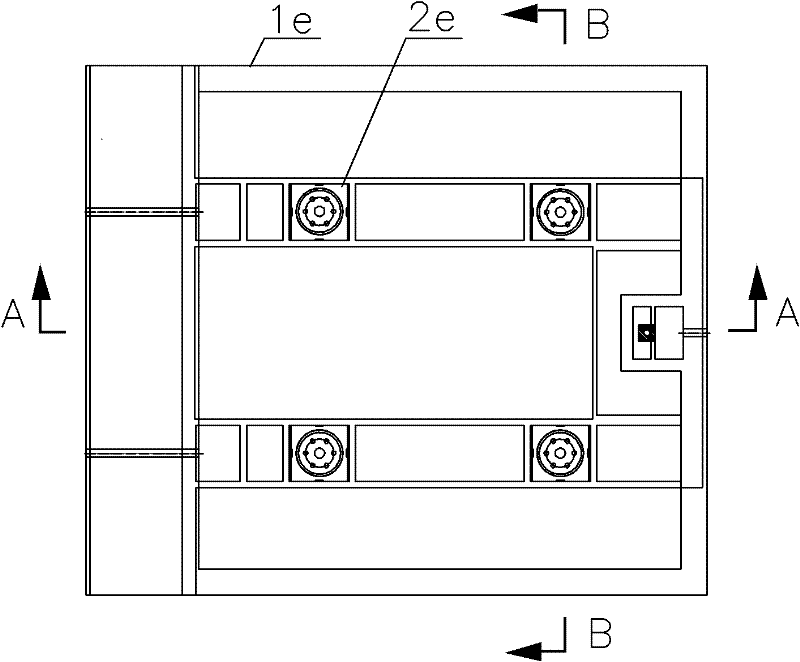

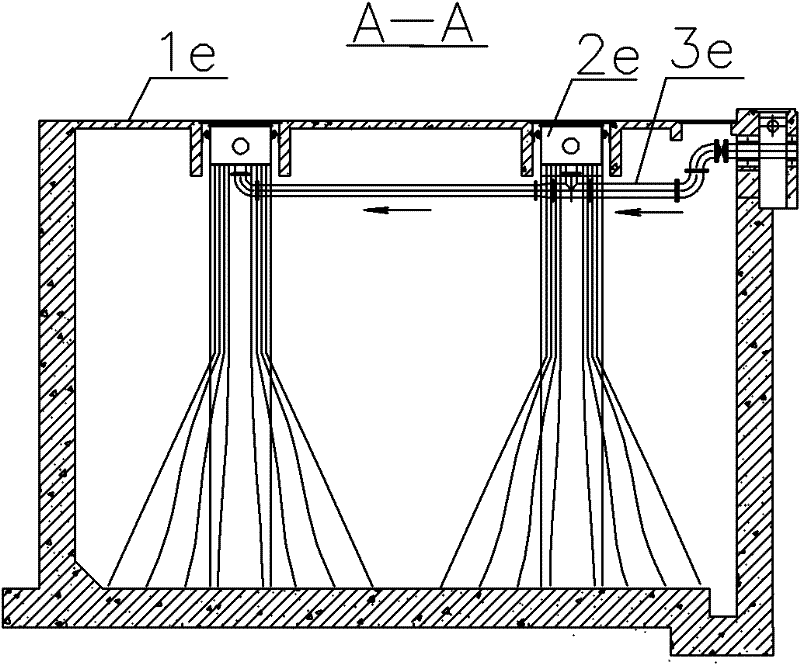

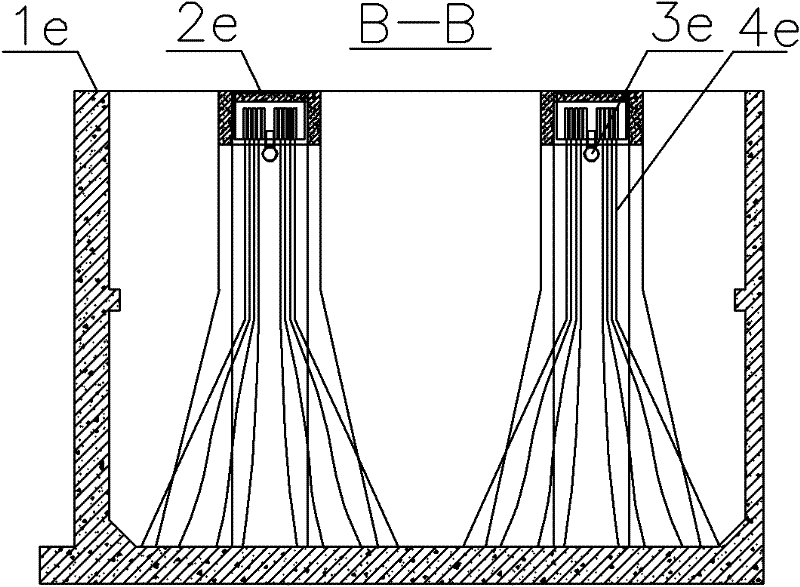

[0030] After being used in Tianjin Jinnan Shuangqiao Sewage Treatment Plant, the area is 12m×12m=144m 2 In the hydrolytic acidification tank, two distribution channels with a length of 12 meters and a width of 1.4 m are installed. Each distribution channel is equipped with 70 DN40 water distribution pipes and one DN50 vent pipe. During installation, the elevation error of the upper port of the water distribution pipe ≤±2mm; the diameter of the outlet hole of the water distribution pipe 4 is φ40mm; facing the lower port of the water distribution pipe, a conical top reflector 10 is installed on the bottom of the pool, and the distance between the water distribution pipe and the cone tip of the conical top reflector 10 is 60mm, and the distance between the water distribution pipe and the hydrolysis acidification pool The distance between the bottom surface is 290mm; the water distribution pipes are positioned at their lower ports, and their distribution density = 1 piece / m 2 , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com