Method and apparatus for preparing high temperature composite gasifying agent

A technology of gasification agent and high-temperature flue gas, which is applied in chemical instruments and methods, combustion methods, inorganic chemistry, etc., can solve the problems of high nitrogen content, large oxygen consumption, and reduction, and achieve stable temperature and components, and thermal efficiency High, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

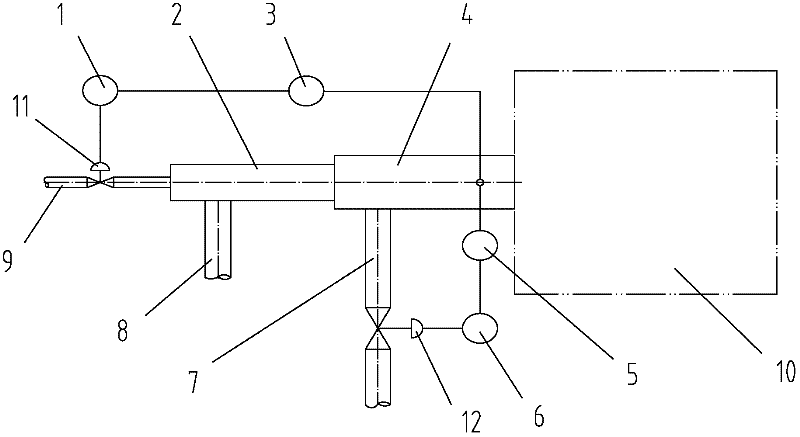

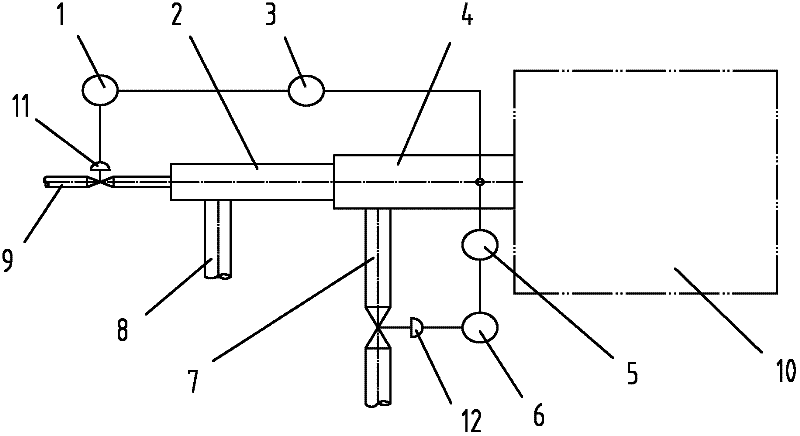

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] A preparation method of a high-temperature composite gasification agent, the composite gasification agent contains CO 2 、H 2 O, O 2 and N 2 gas, CO 2 The volume percentage is 8-12%, H 2 The volume percentage of O is 15-18%, O 2 The volume percentage is 7-10%. First, the gas fuel is burned by the burner, and the excess air coefficient is controlled at 1.05-1.2 to generate high-temperature flue gas. The temperature of the flue gas is controlled at 1100-1300°C. 2 The volume percentage is 8-12%, H 2 The volume percentage of O is 15-18%, and a certain amount of oxygen is added to the high-temperature flue gas so that the volume percentage of oxygen in the high-temperature flue gas reaches 7-10%.

[0022] like figure 1 As shown, the burner 2 is connected with a gas pipe 9 and an air pipe 8, the outlet of the burner 2 is connected with a smoke e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com