Austenitic stainless steel containing rare-earth element

A technology for austenitic stainless steel and rare earth elements, applied in the field of stainless steel, can solve the problems of strengthening and low strength, and achieve the effects of improving high temperature oxidation resistance, improving mechanical performance indicators, and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] The austenitic stainless steel of the present invention is prepared by using the 304 stainless steel bar and rare earth alloy produced by Taiyuan Iron and Steel as raw materials. The chemical composition and weight percentage of the austenitic stainless steel are: C 0.04%, Cr 17.1%, Mn 0.52%, Ni 8.6 %, rare earth 0.042%, Si 0.08%, P 0.019%, S 0.015%, Fe balance.

Embodiment 2

[0009] The austenitic stainless steel of the present invention is prepared by using the 304 stainless steel bar and rare earth alloy produced by Taiyuan Iron and Steel as raw materials. The chemical composition and weight percentage of the austenitic stainless steel are: C 0.03%, Cr 18.9%, Mn 0.67%, Ni 10.4 %, rare earth 0.054%, Si 0.06%, P 0.017%, S 0.016%, Fe balance.

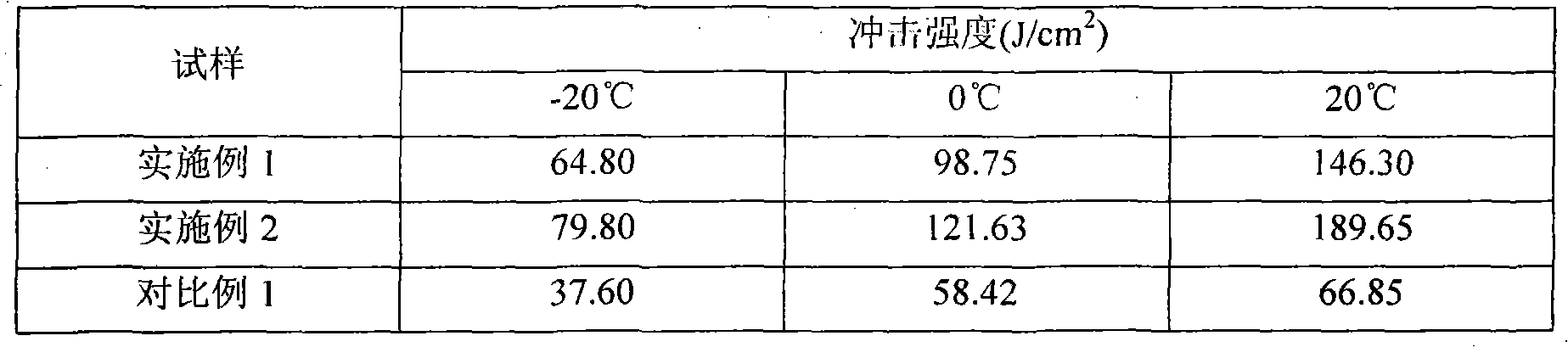

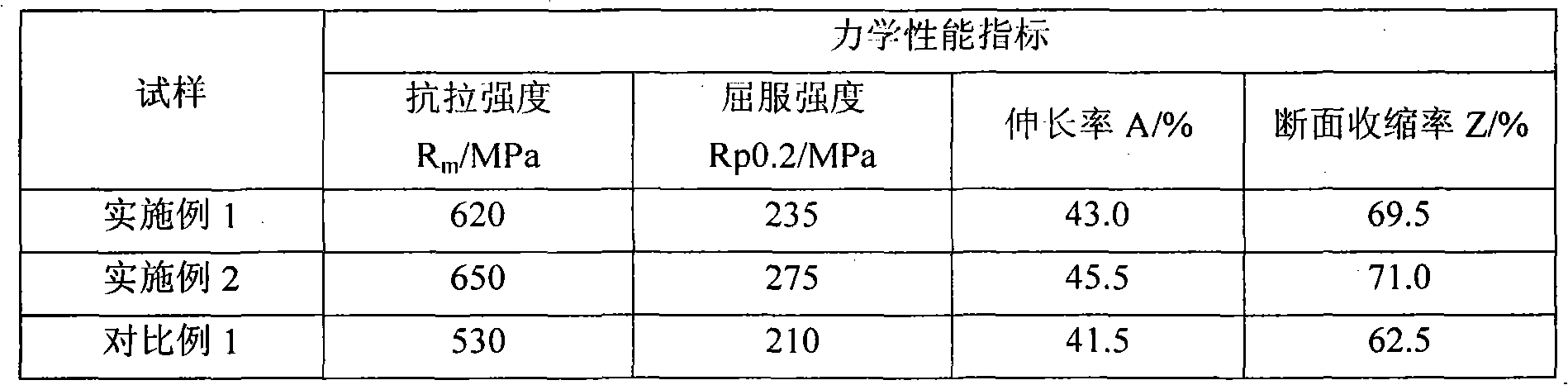

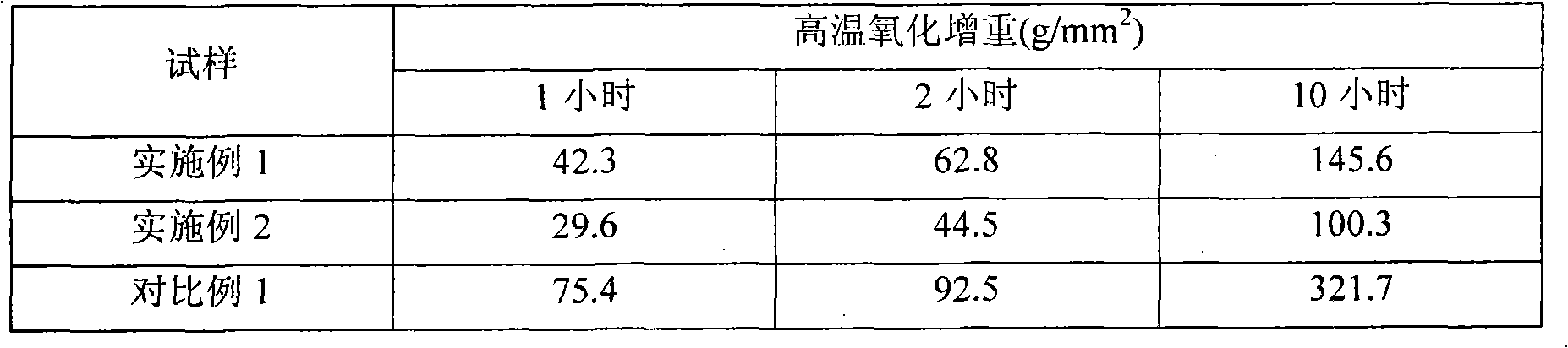

experiment example 1

[0012] Experimental example 1: Determination of the solidification structure of stainless steel

[0013] The columnar grain domain width and central equiaxed grain domain width of the stainless steels of Example 1, Example 2 and Comparative Example 1 were observed under a microscope by metallographic corrosion method, and the results are shown in Table 1 below.

[0014] Table 1. Solidification structure of rare earth-added and 304 austenitic stainless steel

[0015] sample

[0016] It can be seen from Table 1 that after the addition of rare earths, the width of the columnar crystal region decreases, while the width of the central equiaxed crystal region increases, indicating that rare earths can improve the solidification structure of austenitic stainless steel and increase the volume fraction of equiaxed crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com