Pirani vacuum gauge of carbon nanotube and vacuum degree detection method thereof

A carbon nanotube and detection method technology, applied in the field of microelectronics, can solve the problems of large volume, low sensitivity, small measurement range, etc., and achieve the effects of small volume, high sensitivity, and wide pressure measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

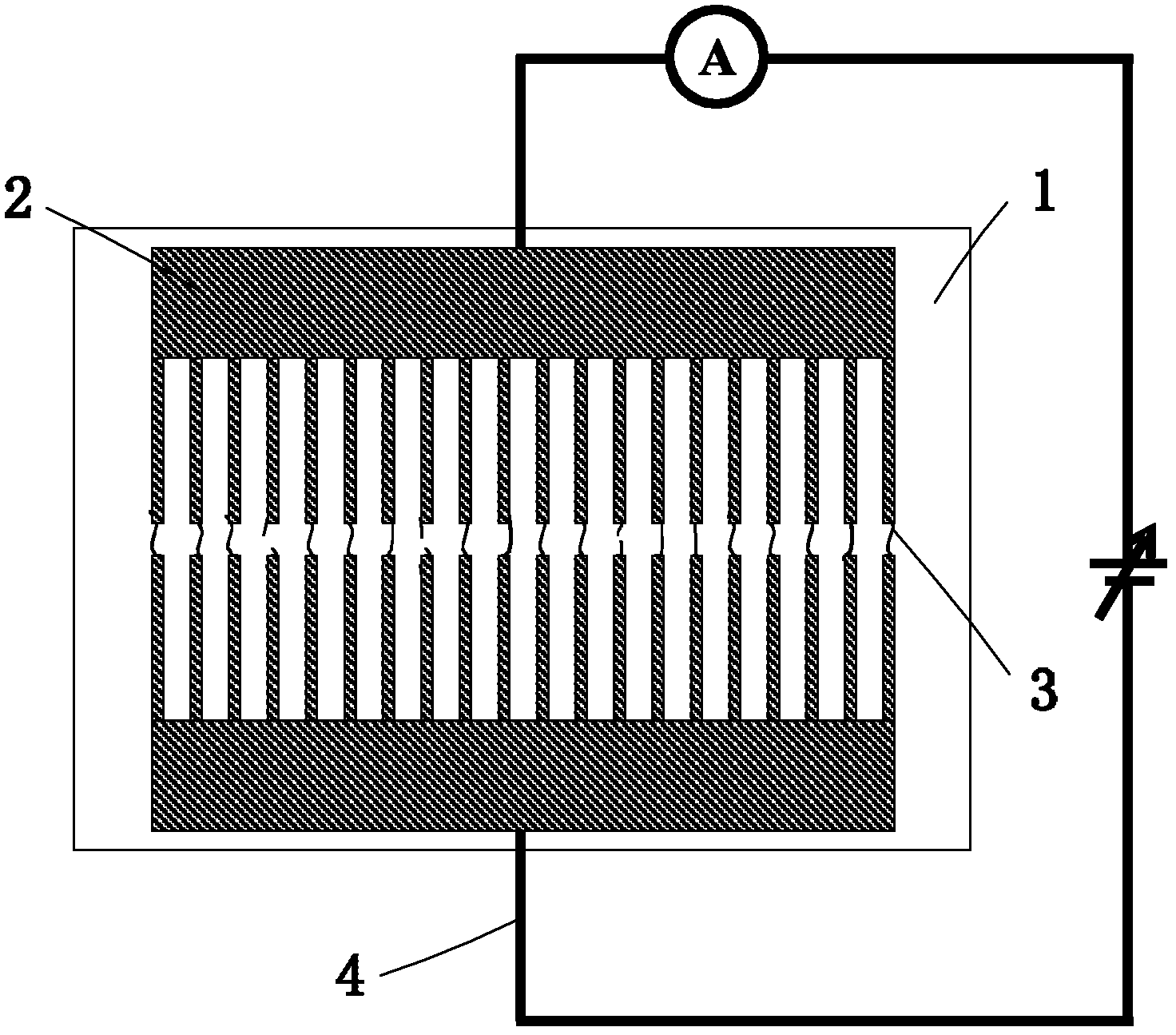

[0031] Attached below Figure 1 to Figure 3 The present invention will be further described in detail with specific embodiments:

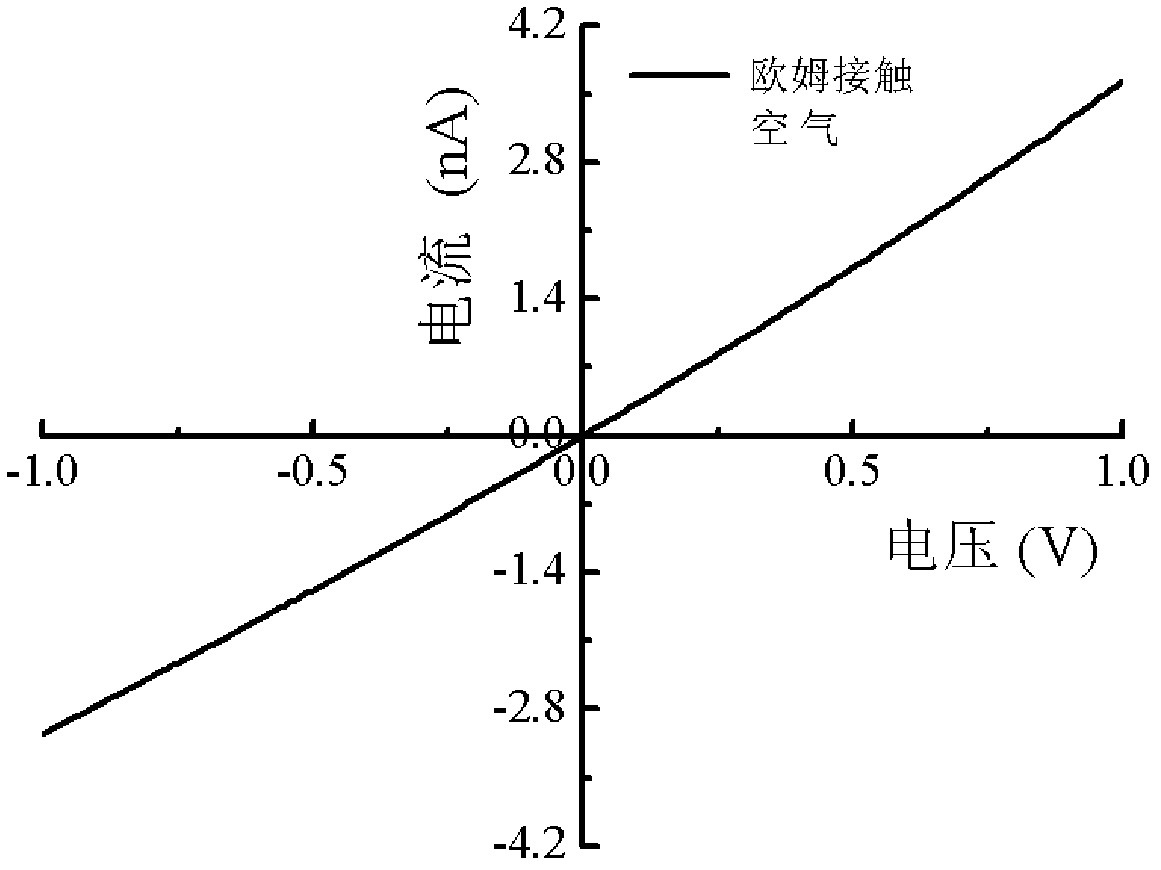

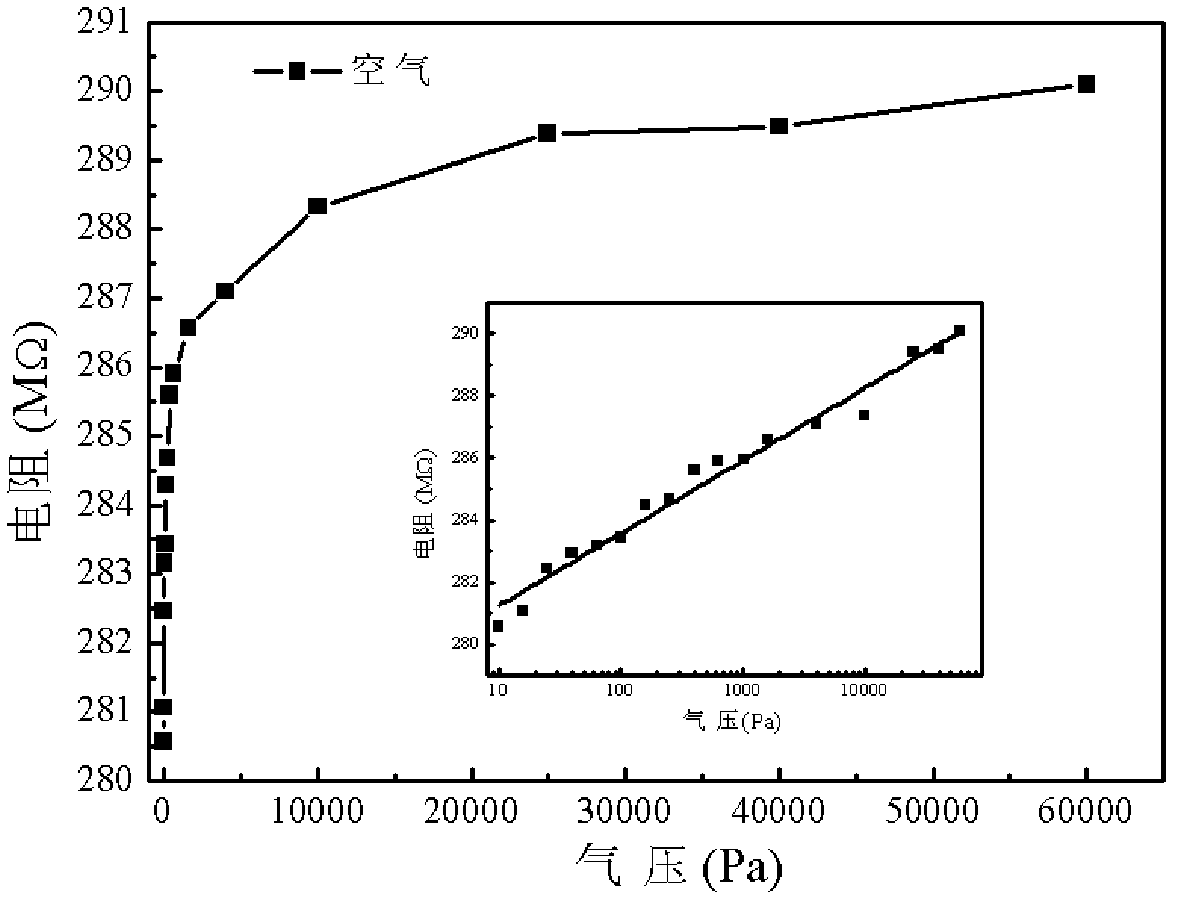

[0032] The carbon nanotube Pirani vacuum gauge of the present invention includes a single carbon nanotube or carbon nanotube bundle, multiple carbon nanotubes or carbon nanotube bundles, and the carbon nanotubes are electrically connected to an external measurement circuit through a metal electrode pair. Interlinked. When the air pressure is different, the gas thermal conductivity is different, which causes the resistance of the carbon nanotubes in the test circuit to change, and the value of the air pressure change is measured. The gas pressure measurement range of the carbon nanotube Pirani vacuum gauge can be adjusted by using different types or numbers of carbon nanotubes. In this example, the detectable pressure range of the carbon nanotube Pirani vacuum gauge of the present invention is wide ranging from 10 to 60,000 Pa. This range is mainly l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com