Flexible pressure resistance flow field sensor based on single-wall carbon nanotube array and manufacturing method thereof

A single-walled carbon nanotube and a production method technology are applied in the fields of sensors and precision instruments, which can solve the problems of low sensitivity of carbon nanotube flexible piezoresistive sensors, inability to precisely control carbon nanotubes, and only reach 1.8 in height, etc. Linearity and Sensitivity, Effects of High Intensity, High Sensitivity Sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

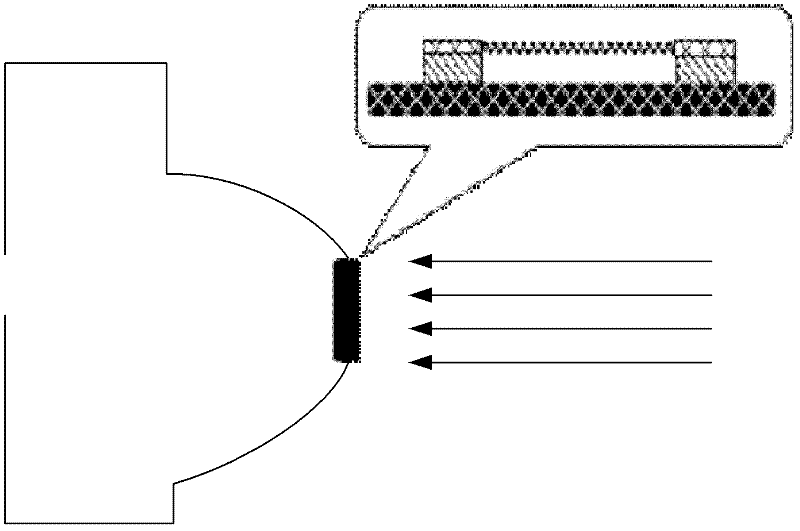

[0060] Such as figure 2 Shown is a schematic diagram of measuring airspeed at the leading edge of a wing of a micro-aircraft or a cruiser using a flexible piezoresistive flow field sensor based on a single-walled carbon nanotube array according to an embodiment of the present invention.

[0061] Specifically, holes are punched on the surface of the leading edge of the wing of a micro-aircraft or cruiser that needs to measure airspeed, the size of the holes is slightly smaller than the size of the single-walled carbon nanotube array flexible piezoresistive sensor 100, and then the single-walled carbon nanotubes The array flexible piezoresistive sensor 100 is glued to the surface of the hole, and then through the first lead and the second lead of the single-wall carbon nanotube array flexible sensor 100, the connection with the signal processing circuit and other equipment is realized, and then, when the micro-aircraft or cruiser During flight, according to the formula (1) ment...

Embodiment 2

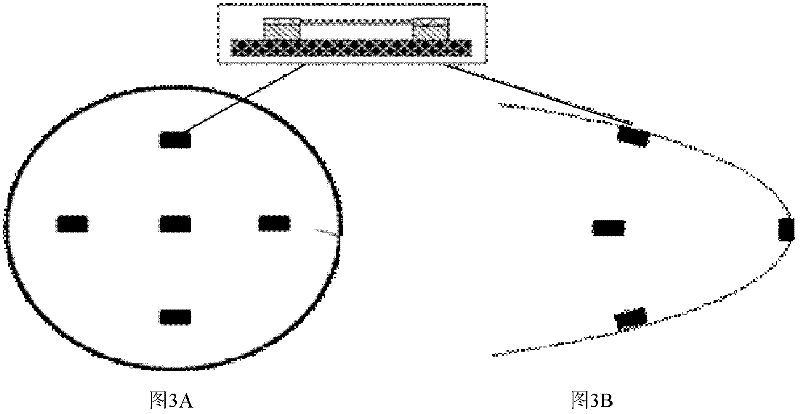

[0063] Such as Figure 3A-3B Shown are the front view and the left view, respectively, of measuring the pitch angle and deflection angle of the wing of a micro-aircraft or cruiser using the flexible piezoresistive sensor based on the single-walled carbon nanotube array according to the embodiment of the present invention. As a specific application, first manufacture the conical detection structure as shown in Figure 3, and punch 5 holes on its surface, the size of each hole is slightly smaller than the size of the single-walled carbon nanotube array flexible piezoresistive sensor 100, and then Glue the sensor 100 to the surface of each hole to form a symmetrical structure as shown in the figure, and realize the connection with peripheral devices such as signal processing circuits, and then install the conical detection structure on the micro-aircraft or cruiser that needs to measure the angle of attack above (such as the head), when the pitch angle or deflection angle between ...

Embodiment 3

[0065] Such as Figure 4 As shown, it is a schematic diagram of measuring the flow velocity distribution at the leading edge of a wing of a micro-aircraft or a cruiser using a flexible piezoresistive sensor based on a single-walled carbon nanotube array according to an embodiment of the present invention. First, an array of holes is processed on the surface of the leading edge of the wing of the micro-aircraft or cruiser, and the size of each hole is slightly smaller than the size of the single-walled carbon nanotube array flexible piezoresistive sensor 100, and then the sensor 100 is glued to the micro-aircraft or An array of holes machined into the surface of the leading edge of a cruiser wing. Such as Figure 4 As shown, when the MAV or cruiser is flying, the pressure value of the flexible sensor array is read out, therefore, the measurement of the flow velocity distribution at the leading edge of the wing of the MAV or cruiser can be realized according to the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap