Preparation method for water-soluble sulfonated calixarene

A sulfonated calixarene, water-soluble technology, applied in the field of preparation of functional compounds, can solve the problems of low product purity, unsatisfactory mixed acids and salts, etc., and achieve the effect of simple purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

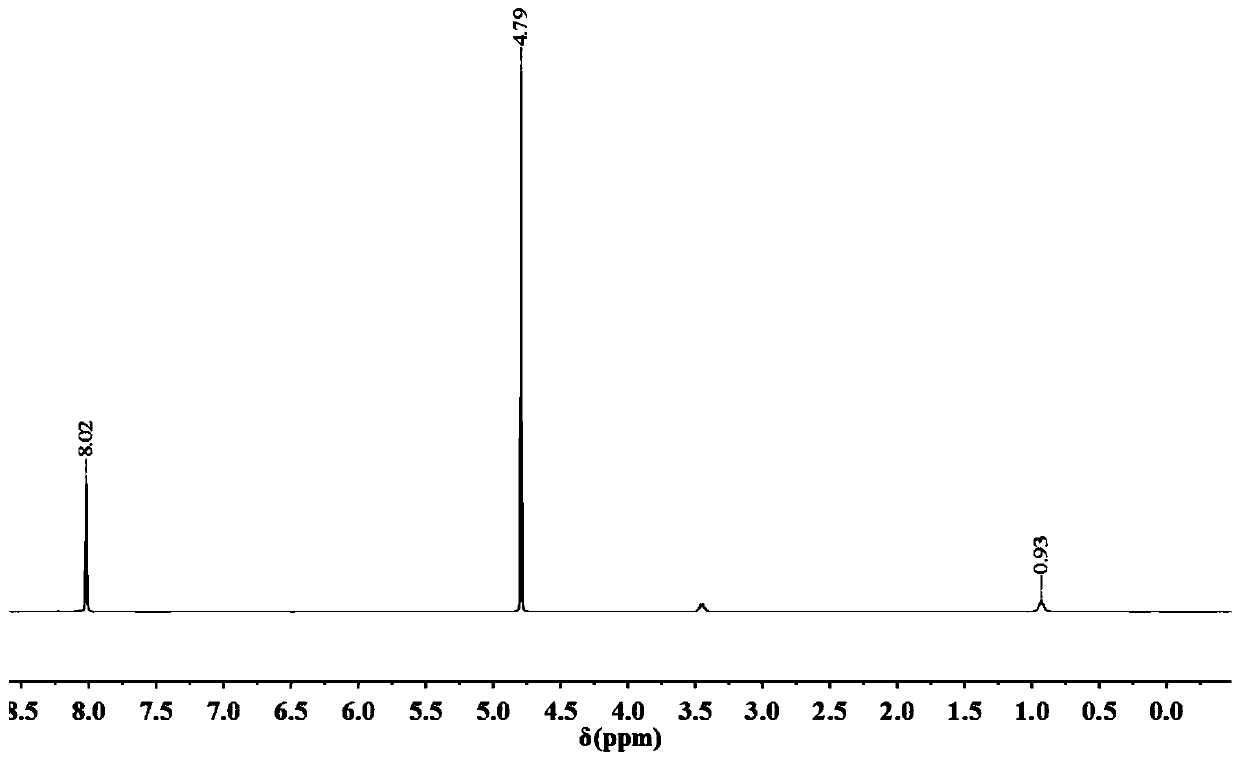

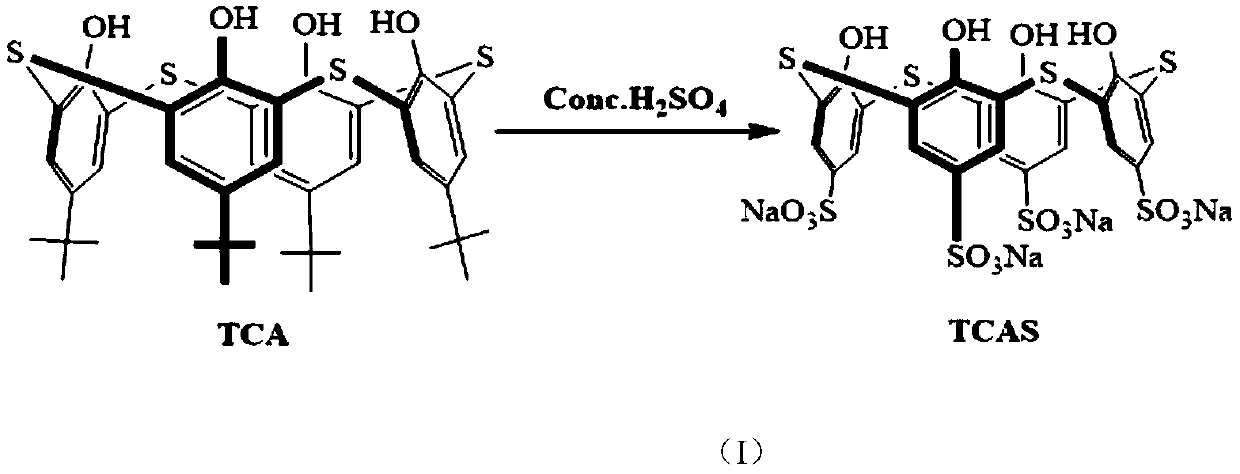

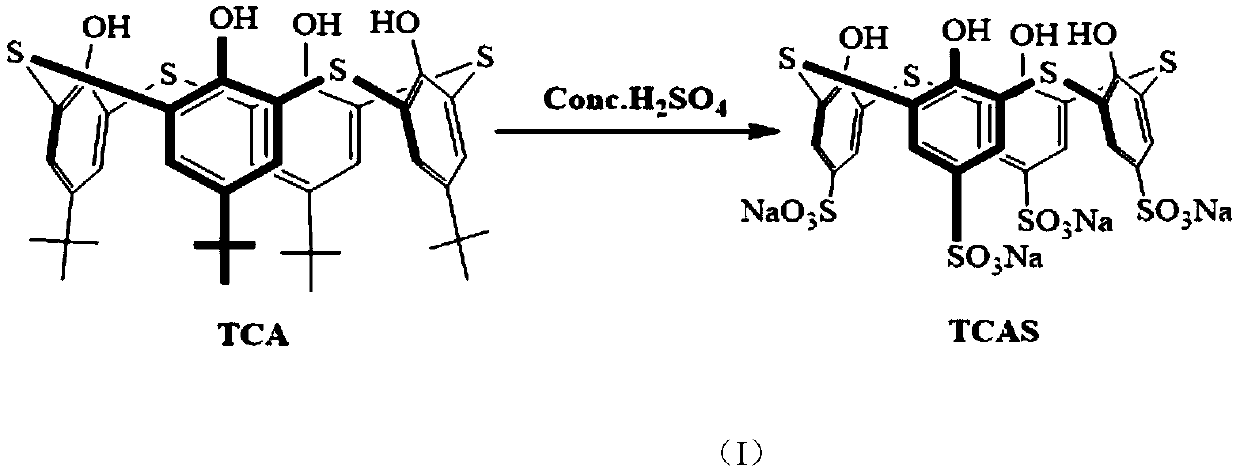

Embodiment 1

[0029] Add 100 mL of concentrated sulfuric acid with a concentration of 98% to a three-port reaction vessel equipped with a temperature-controlled base, then accurately weigh 2 g of calixarene (TCA) and add it to the concentrated sulfuric acid, adjust the temperature of the temperature-controlled base to ensure that the reaction temperature is at 80 ° C, and the reaction A polytetrafluoroethylene stirring paddle was used for stirring in the vessel. During the reaction process, the reaction process is monitored by monitoring the solubility of the reaction solution in water, and the reaction is complete if the reaction solution is completely water-soluble. After reacting for about 20 hours, take a drop of the reaction solution and drop it into 10mL aqueous solution every 1 hour, and observe whether it can be completely dissolved in 10mL water. After 24 hours of final reaction, all the reactants can be dissolved in water, and the solution is clear and transparent, indicating that ...

Embodiment 2

[0033] Add 180mL of concentrated sulfuric acid (98% concentration) to a three-port reaction vessel with a temperature-controlled base, then accurately weigh 3g of calixarene (TCA) and add it to the concentrated sulfuric acid to adjust the temperature of the temperature-controlled base to ensure that the reaction temperature is at 85°C. The reactor is stirred with a polytetrafluoroethylene stirring paddle. During the reaction process, the reaction process is monitored by monitoring the solubility of the reaction solution in water, and the reaction is complete if the reaction solution is completely water-soluble. After reacting for about 15 hours, take a drop of the reaction solution and drop it into 10mL aqueous solution every 1 hour, and observe whether it can be completely dissolved in 10mL of water. After 22 hours of final reaction, all the reactants can be dissolved in water, and the solution is clear and transparent, indicating that the reaction completely. Then cooling t...

Embodiment 3

[0037]Add 60mL of concentrated sulfuric acid (98% concentration) to a three-port reaction vessel with a temperature-controlled base, then accurately weigh 1.0g of calixarene (TCA) and add it to the concentrated sulfuric acid, adjust the temperature of the temperature-controlled base to ensure that the reaction temperature is at 75°C , The reactor is stirred with a polytetrafluoroethylene stirring paddle. During the reaction process, the reaction process is monitored by monitoring the solubility of the reaction solution in water, and the reaction is complete if the reaction solution is completely water-soluble. After reacting for about 20 hours, take a drop of the reaction solution and drop it into 10mL aqueous solution every 1 hour, and observe whether it can be completely dissolved in 10mL water. After 28 hours of final reaction, all the reactants can be dissolved in water, and the solution is clear and transparent, indicating that the reaction completely. Then cool the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com