Apparatus and method for manufacturing laminated electronic component

A technology for electronic components and manufacturing devices, which is applied in the fields of capacitor manufacturing, semiconductor/solid-state device manufacturing, inductor/transformer/magnet manufacturing, etc., and can solve the problems of increased energy consumption such as power, heavy suction roller weight, stacking position deviation, etc. problem, to achieve the effect of reducing the transmission positioning deviation, increasing the production line speed, and reducing the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

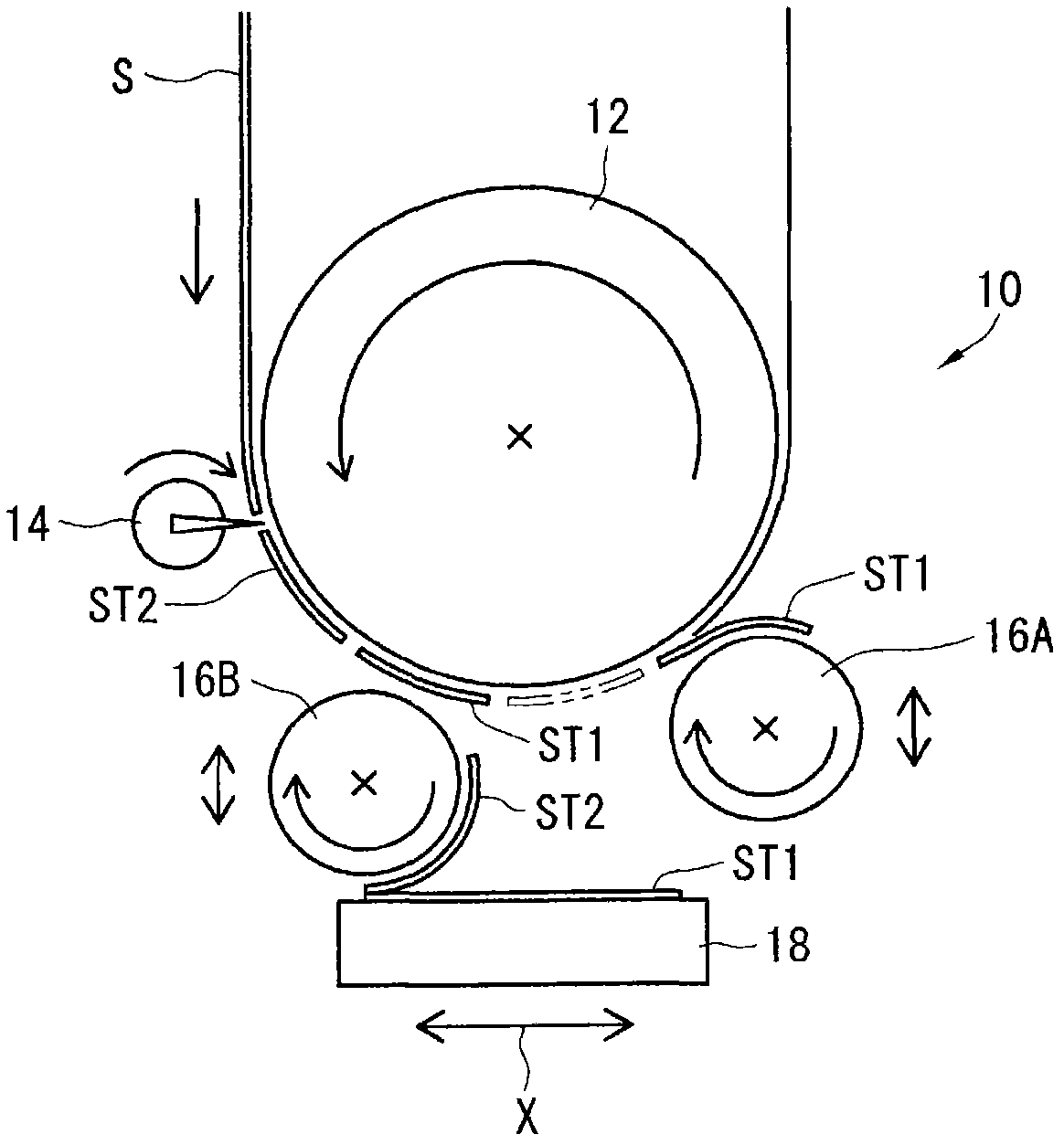

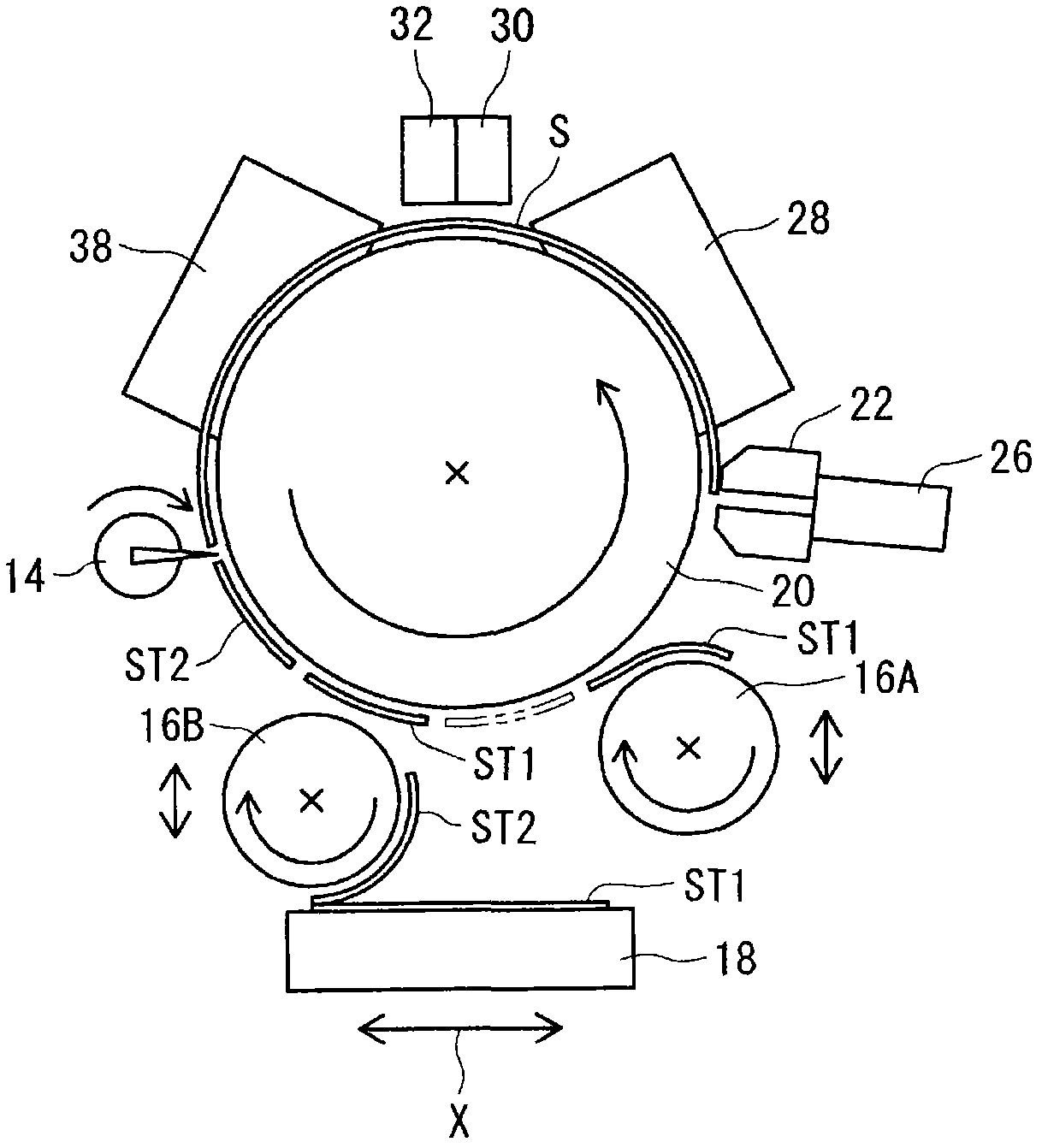

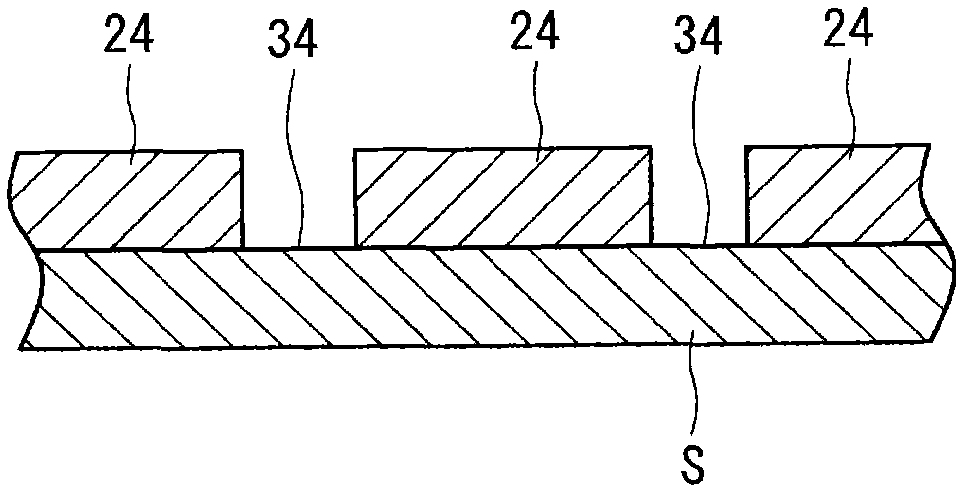

[0032] The multilayer electronic component manufacturing apparatus and the multilayer electronic component manufacturing method according to the first embodiment of the present invention will be described with reference to the drawings. In addition, multilayer electronic components such as multilayer ceramic capacitors and multilayer ceramic inductors are included in the "multilayer electronic component" which is the object of manufacture of the present invention. Next, a multilayer ceramic capacitor will be described as an example of a multilayer electronic component.

[0033] First, a multilayer electronic component manufacturing apparatus will be described.

[0034] In addition, in the first embodiment, the elongated ceramic sheet on which the electrode circuit (internal electrode) and the dielectric coating film have been formed is continuously (non-intermittently) conveyed by a sheet conveying roller described below.

[0035] Such as figure 1 As shown, the laminated ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com