Single-circuit output flyback converter controlled in current mode

A flyback converter, current-mode technology, applied in the output power conversion device, the conversion of DC power input to DC power output, and the adjustment of electrical variables, etc., can solve the problem of low switching frequency, poor anti-interference performance, and filter capacitors. The problems of large volume and weight can achieve the effect of reducing surge overvoltage, good rectification effect, and reducing turn-off loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

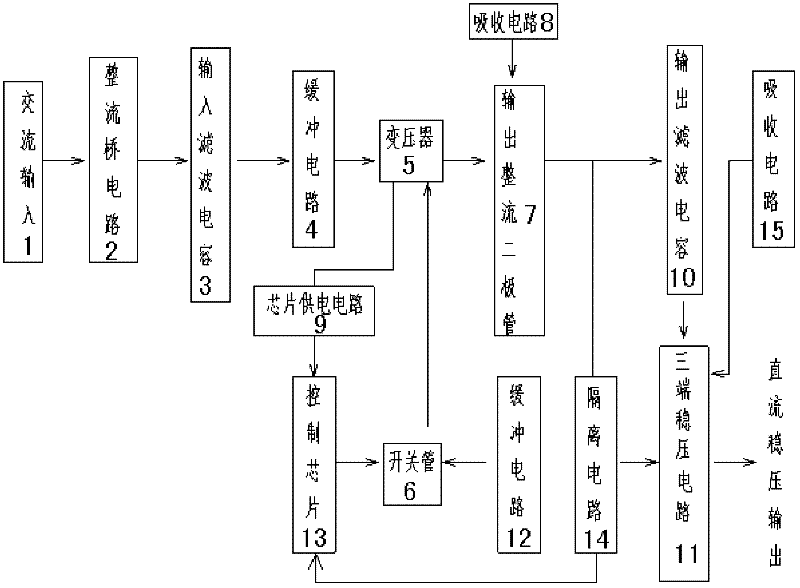

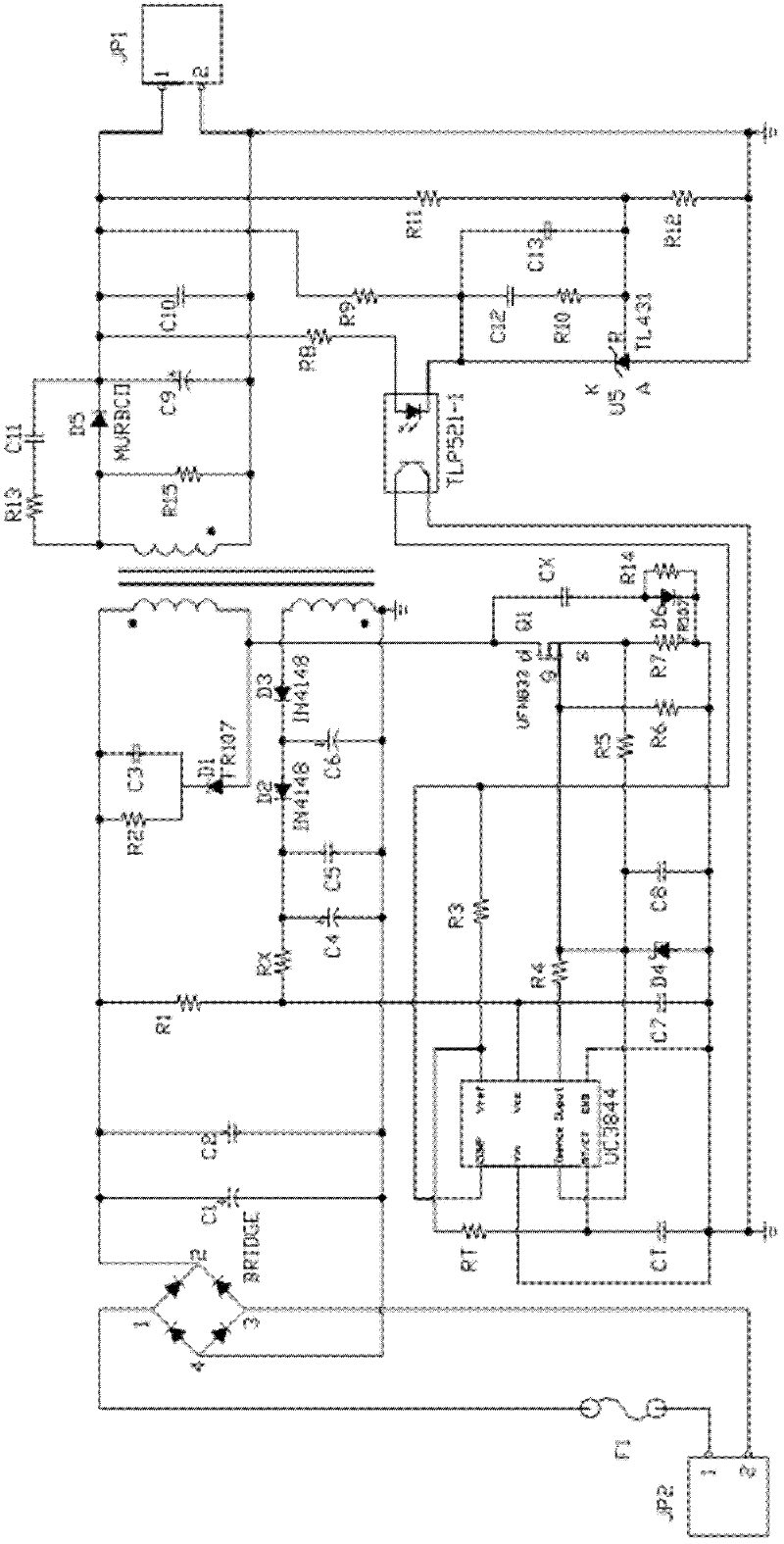

[0020] Such as figure 1 , figure 2 As shown, the present invention includes an AC input source 1, a rectifier bridge circuit 2, an input filter capacitor 3, a first buffer circuit 4, a transformer 5, a switch tube 6, an output rectifier diode 7, a first absorbing circuit 8, and a chip power supply circuit 9. An output filter capacitor 10 , a three-terminal voltage stabilizing circuit 11 , a second buffer circuit 12 , a control chip 13 , an isolation circuit 14 and a second absorbing circuit 15 .

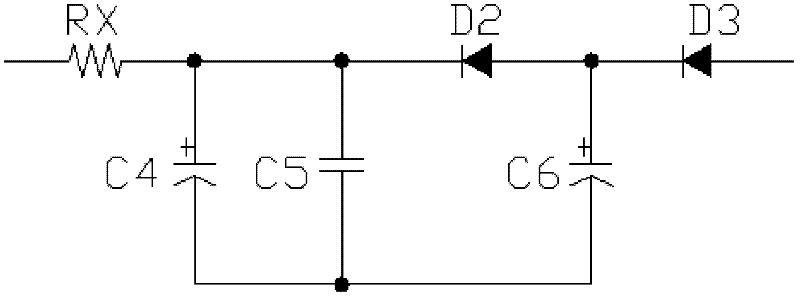

[0021] After the AC input source 1 converts the AC power into unidirectional DC power through the rectifier bridge circuit 2 , the harmonics in the DC power are filtered through the input filter capacitor 3 and then input to the first buffer circuit 4 . The first buffer circuit 4 is connected in parallel to the primary winding of the transformer 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com