Sub-super linear array relay pump system

A relay pump and busbar technology, applied in the field of relay pump system of sub-busbar array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

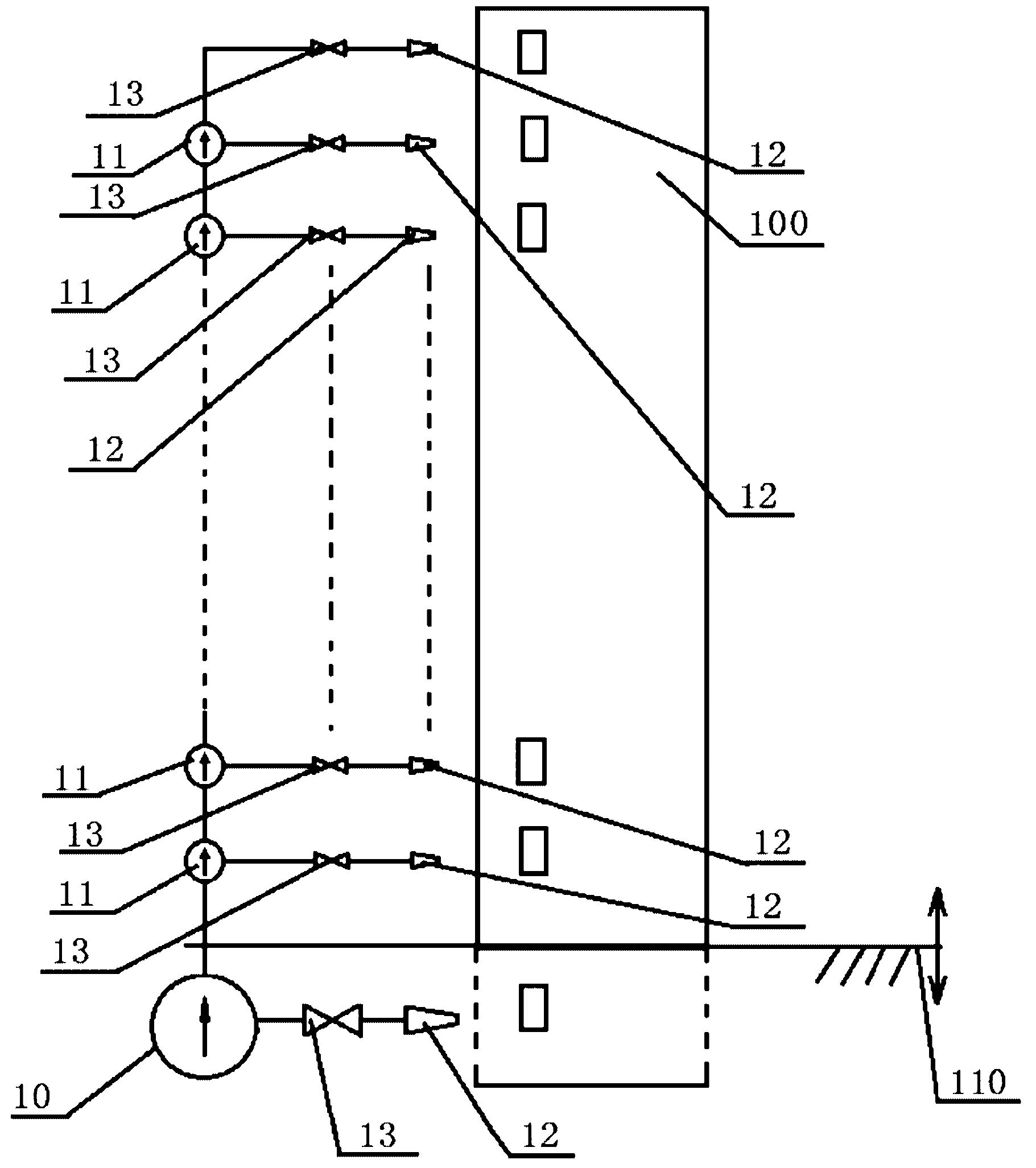

[0029] Embodiment 1: Fixed sub-bus line array relay pump system

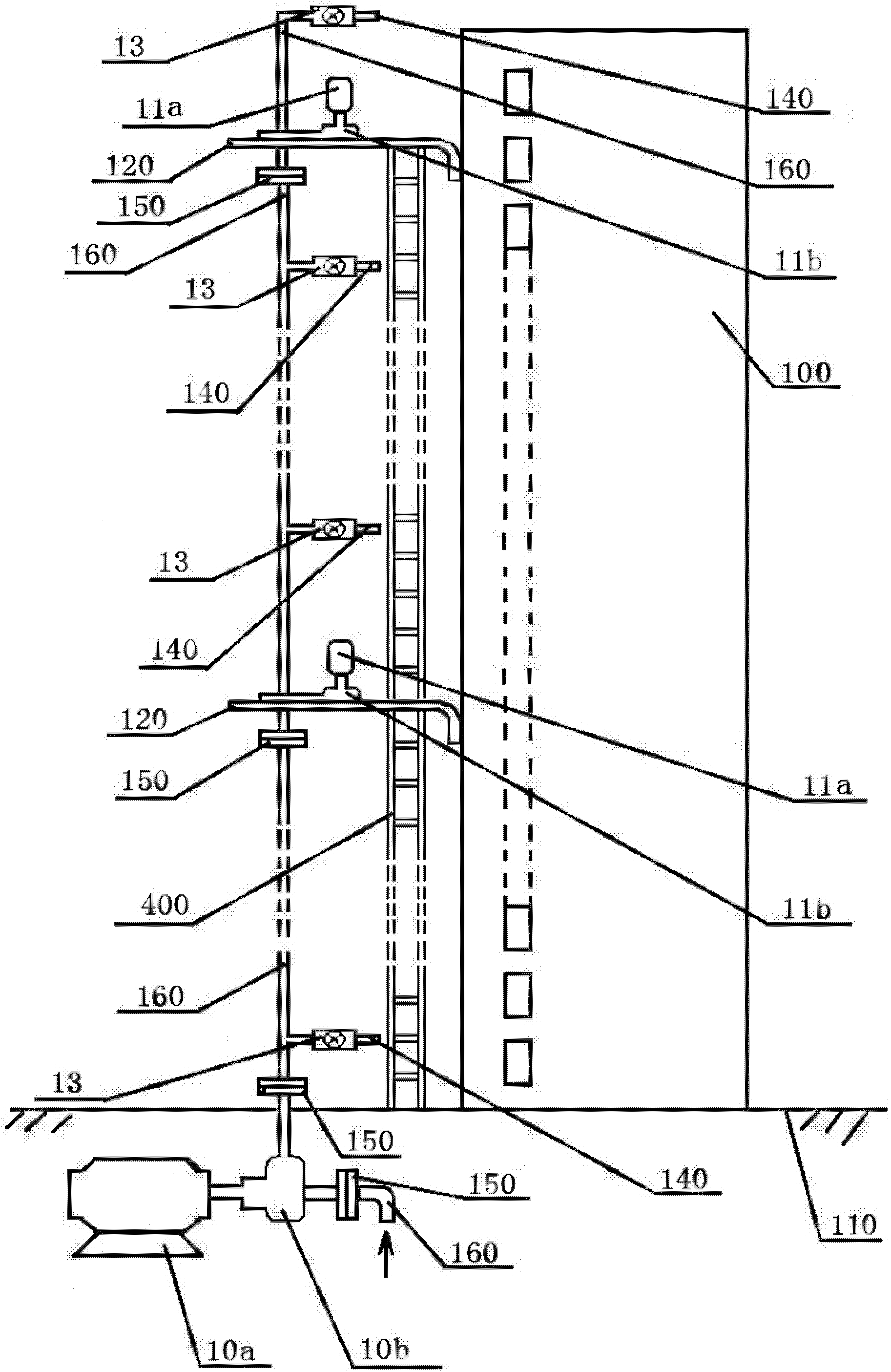

[0030] Such as figure 2 As shown, the sub-bus line array relay pump system is installed outside the window of the walking stairs of the building 100. Because there are less combustible materials up and down the corridor, the fire is relatively small, and it is beneficial to the outside access and up and down activities. The main pump 10 is arranged underground to facilitate the connection of pipelines. There are multiple sub-pumps 11 vertically connected in series on the ground, and the sub-pumps 11 are distributed in a linear array.

[0031] A work platform 120 is installed at a certain height interval on the outside of the building 100, and a sub-pump 11 is housed on each work platform 120. The sub-pump 11 is composed of a sub-pump motor 11a and a sub-pump body 11b. The water pipe 160 on the top, the water pipe 160 is installed with valves 13 and water outlets 140 at intervals according to the height of th...

Embodiment 2

[0034] Example 2: Mobile sub-bus line array relay pump system

[0035] Such as Figure 5 As shown, the mobile sub-bus line array relay pump system is used for firefighters and self-rescue of buildings. The system starts quickly, is flexible in operation and orientation adjustment, and has low environmental requirements. The main pump 10 and the master control system are equipped on the fire truck 601, and the fire truck 601 is externally connected with a sub-pump 11, a water pipe, and an aerial operation warehouse 610. The motor 602 and the winch 603 driven by it are lifted, the helicopter 600 and the winch 603 are connected with a wire rope 604, and the end of the wire rope 604 is provided with a hook 607, and the aerial work warehouse 610 hanging on the hanging fishing 607 is lifted by the control system to carry out the lifting. Rescue.

Embodiment 3

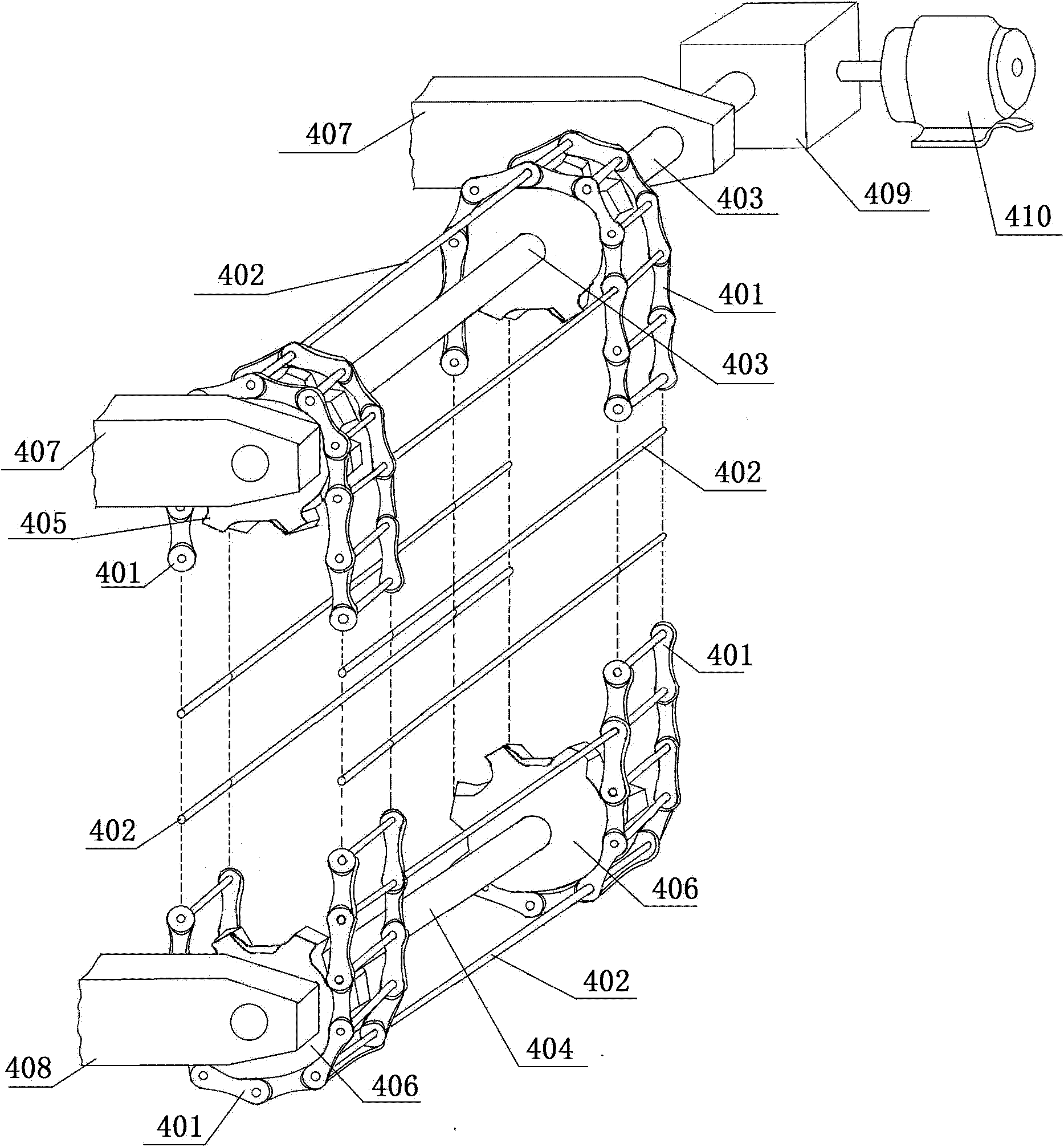

[0036] Example 3: A dedicated fire truck integrating a sub-bus line array relay pump system

[0037] Such as Image 6 , Figure 7 As shown, the integrated fire truck 1100 equipped with the sub-bus line array relay pump system is equipped with an aerial ladder retractable system 1101 and a vehicle-mounted mother pump system 1102. The shaft 1130 is connected by multiple sections. The bottom single-section aerial ladder 1124 is fixed on the vehicle through the ladder seat bracket 1110. It is retracted and unfolded by the aerial ladder retracting system 1101 driven by a hydraulic machine. Each single-section aerial ladder 1124 is equipped with Hydraulic links or small hydraulic presses, hydraulic press outer tubes 1121 and hydraulic press support rods 1122 are used to meet the different opening angle requirements of the aerial ladder; the single-section aerial ladder 1124 is equipped with a graded sub-pump 1112, which is drawn out from the vehicle-mounted main pump system 1102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com