Fully-automatic micro powder screening method with feedback function

A screening method, fully automatic technology, applied in the direction of solid separation, etc., can solve the problems of resource waste, classification time difference, energy consumption, water consumption ratio increase, etc., to achieve high screening efficiency, complete screening grades, and economical The effect of benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

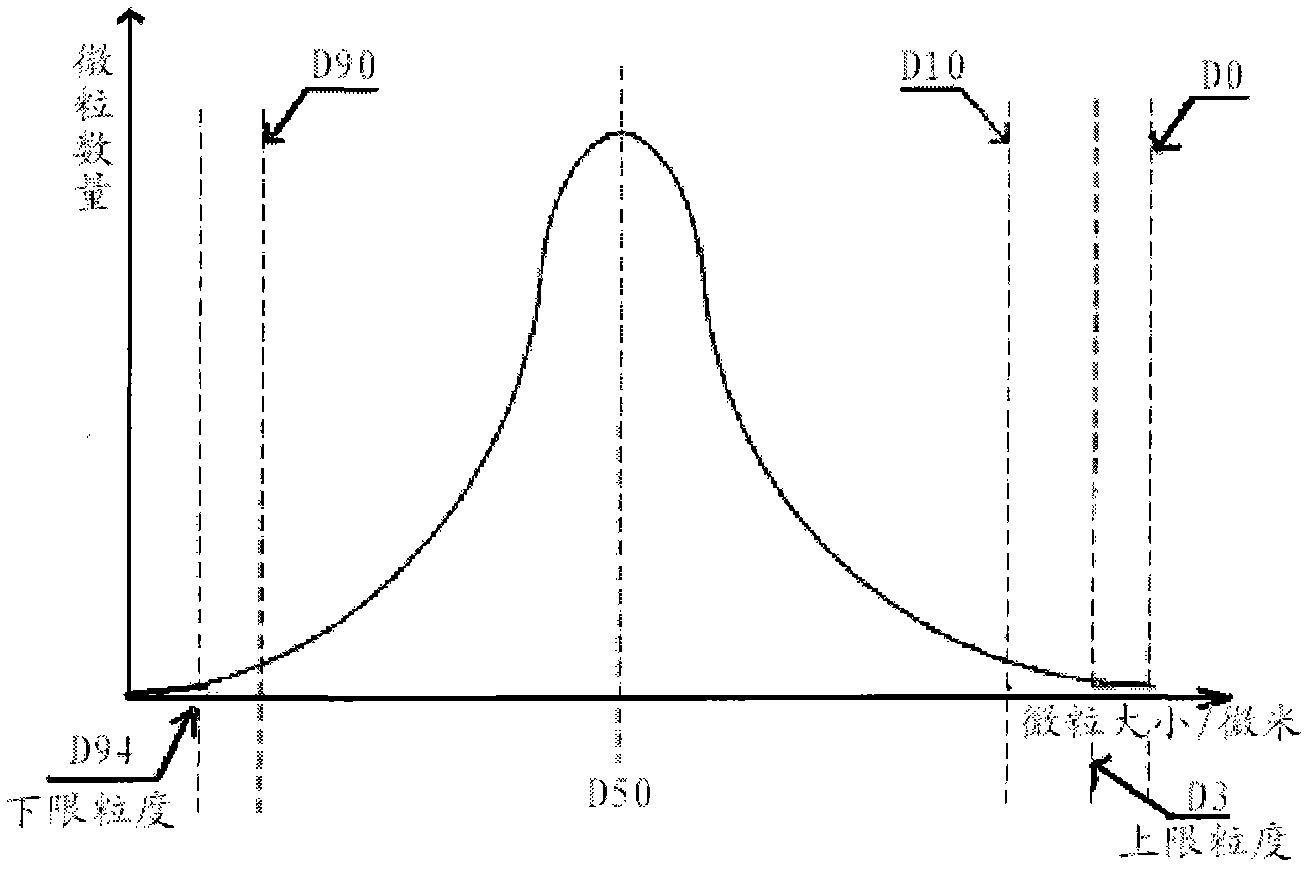

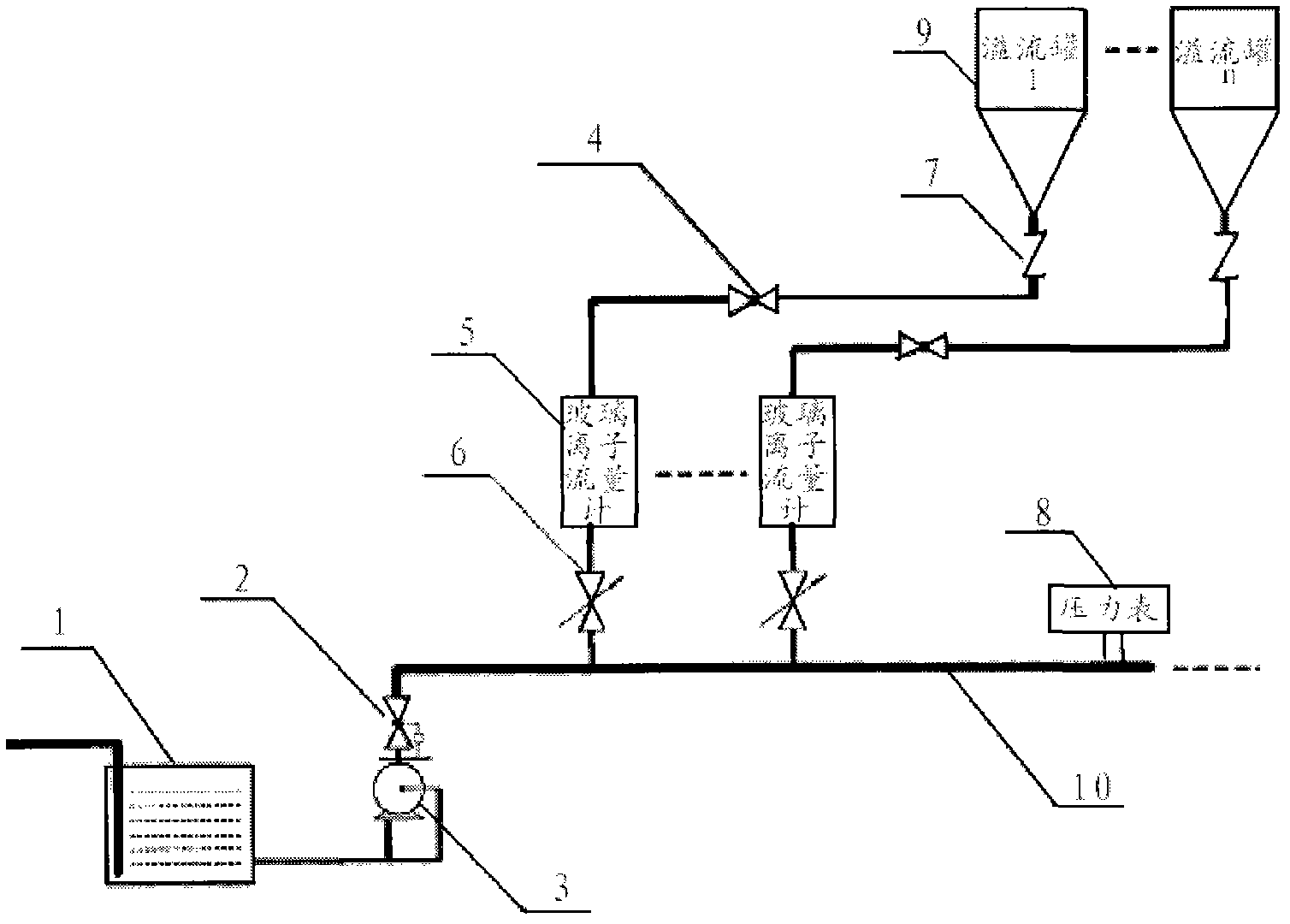

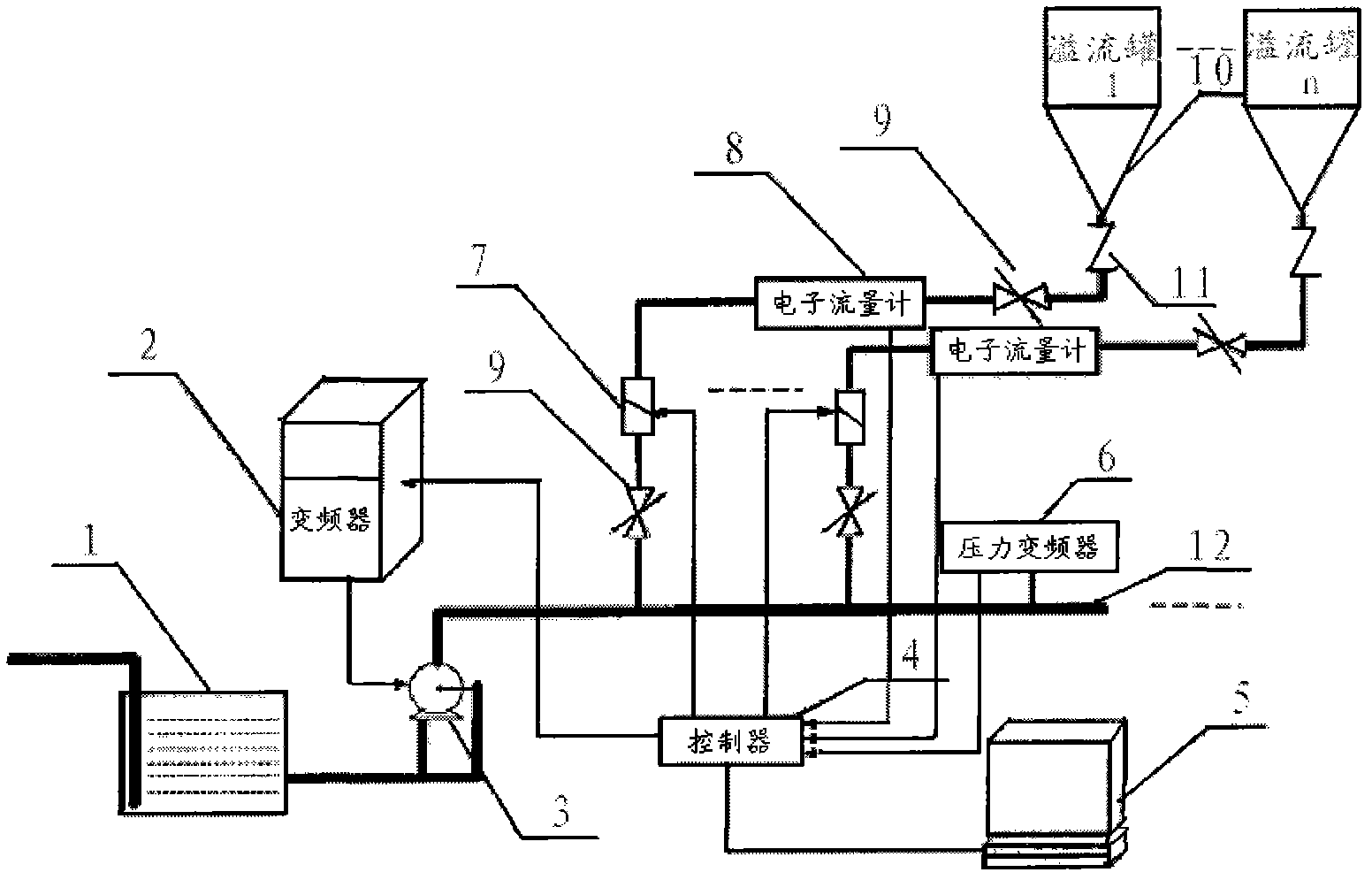

[0057] as attached Figure 4 As shown, the present invention is a fully automatic micropowder screening method with feedback. The method uses a wet method to separate silicon carbide micropowder into products of different labels. The wet method is to control the overflow tank in the micropowder separation device. The flow rate of the internal liquid separates and discharges the particles with different particle sizes in the micropowder; the micropowder separation device controls the separation of the micropowder through the control system, and the control system can control the particle size of the separated various grades of micropowder to be in a normal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com