Automatic disassembly and recovery device for electronic components of waste printed circuit board

A technology of printed circuit boards and electronic components, which is applied in the field of resource utilization of electronic waste, can solve the problems of no mature and feasible technical solutions, achieve the effect of harmless automatic disassembly and separation, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with specific embodiments.

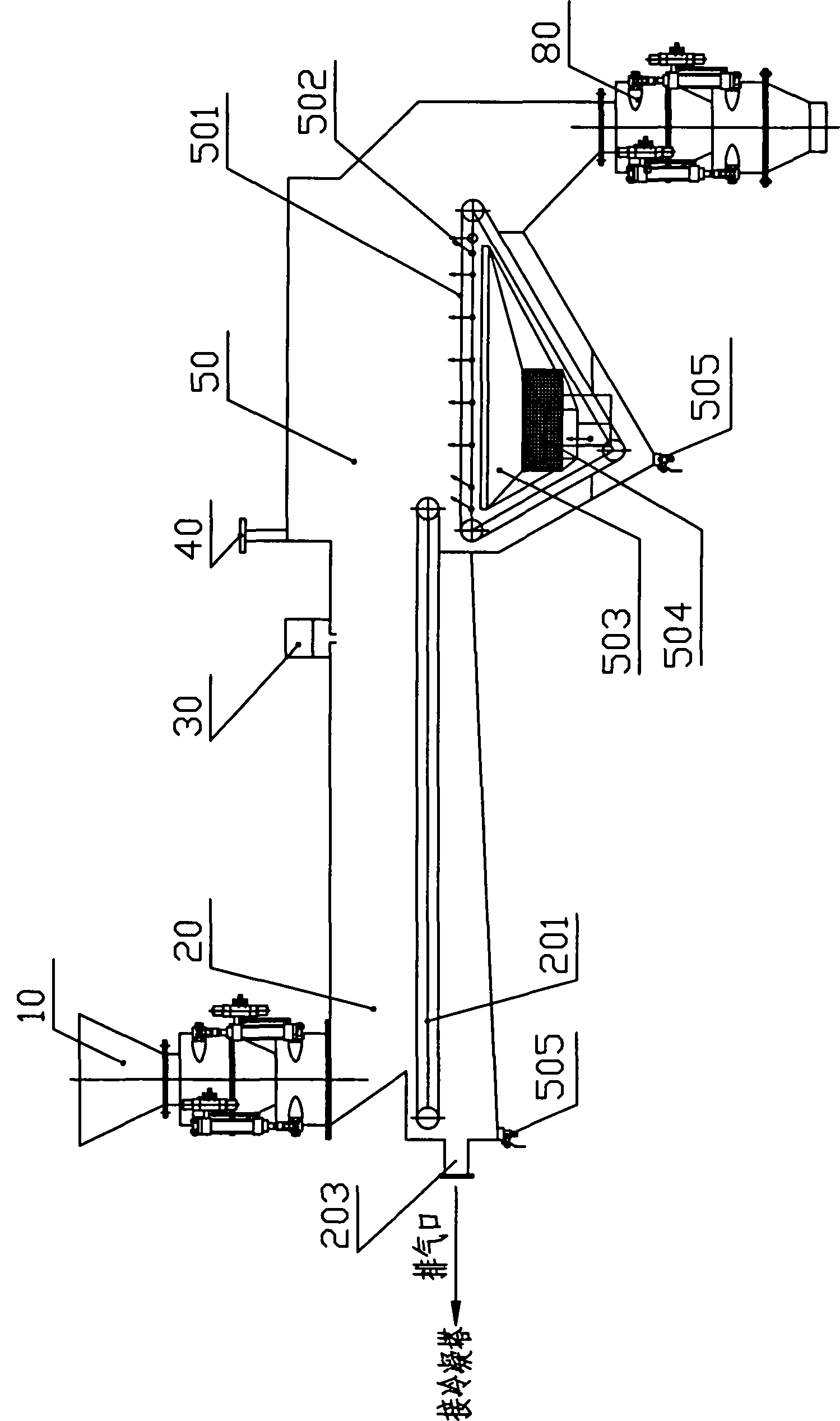

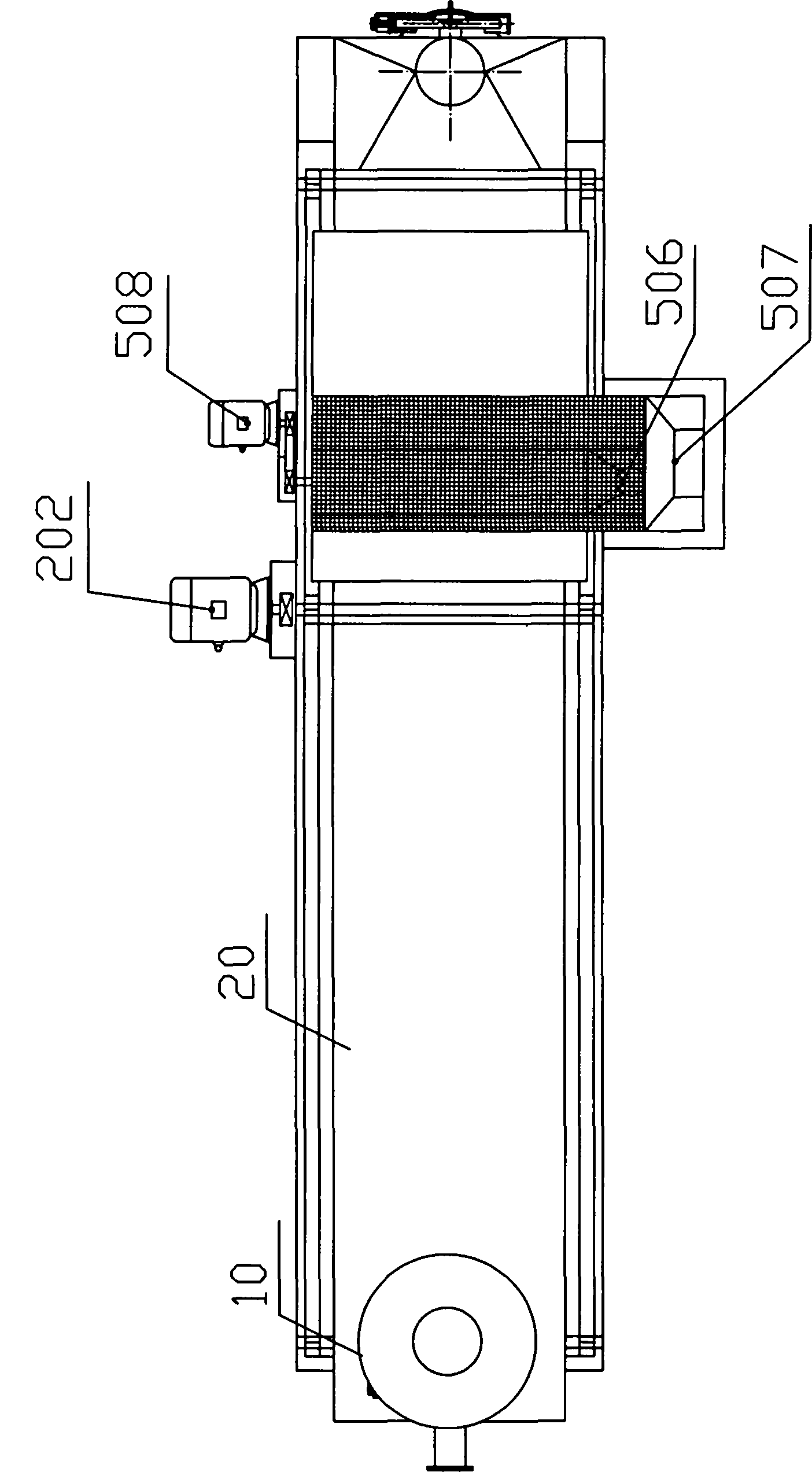

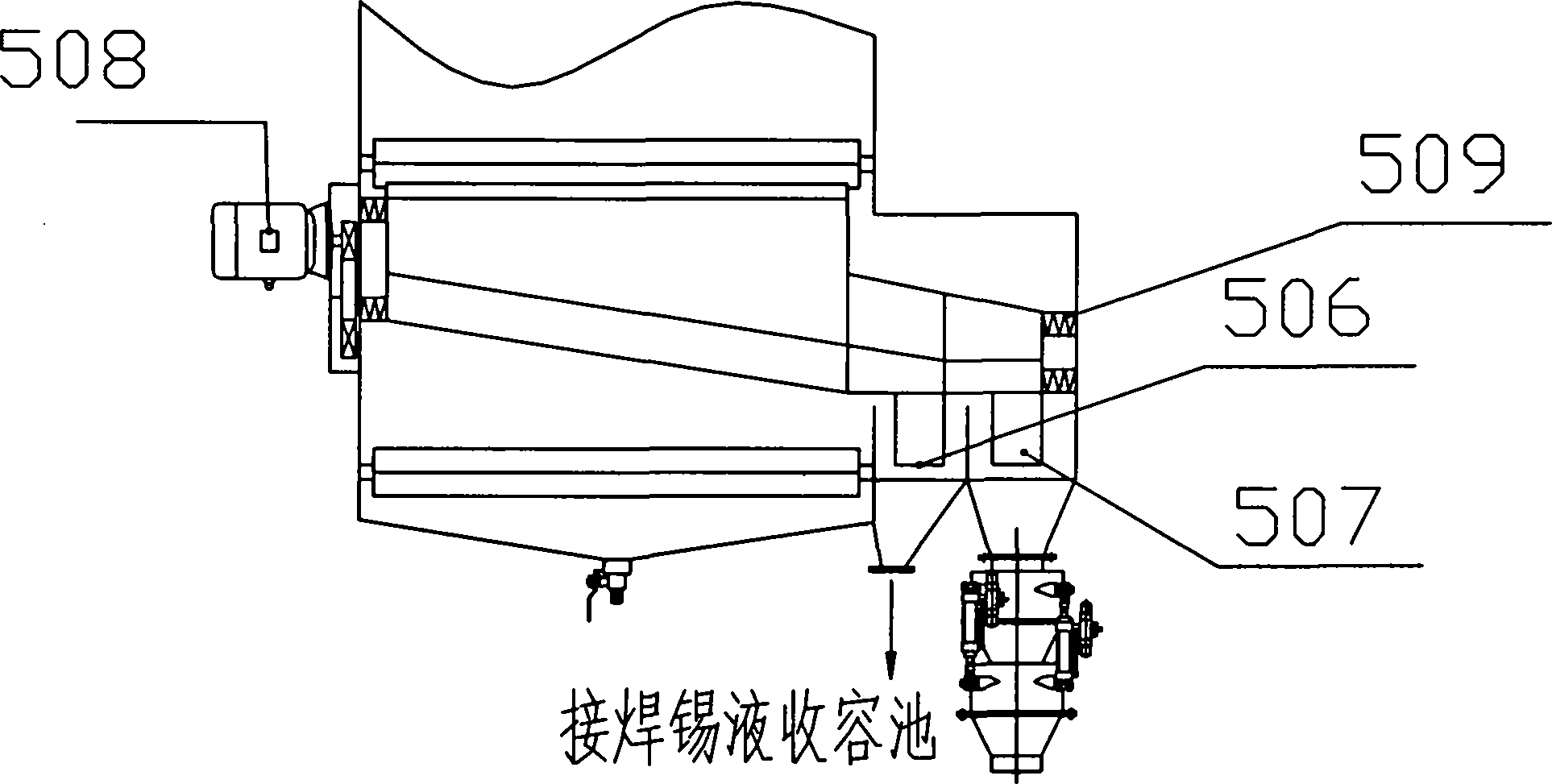

[0017] Such as figure 1 and figure 2 As shown, the waste printed circuit board electronic components automatic disassembly and recovery equipment of the present invention includes a feed flap valve 10, a continuous and gradual rising chamber 20, a pulse vibration disassembly chamber 50, and a discharge flap valve 80, and the four parts are connected as One whole, integrally sealed; the feeding flap valve 10 is connected with the continuous progressive rising greenhouse 20, the continuous progressive rising greenhouse 20 is connected with the pulse vibration dismantling chamber 50, and the pulse vibration dismantling chamber 50 is connected with the discharge flap valve 80. The gas separator 40 is between the continuous gradual rising greenhouse 20 and the pulse vibration disassembly chamber 50; the continuous gradual rising greenhouse 20 is provided with a preheating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com