Continuous casting method and device for double-nozzle cast ultra-thick plate blank

A technology of extra-thick slab and double nozzles, which is applied in the field of continuous casting method and device for casting extra-thick slabs with double nozzles, and can solve the problem of inability to exert mold slag lubrication and heat transfer control capabilities and high probability of longitudinal cracks on the surface of casting slabs , affecting the growth rate of the solidified slab shell, etc., to improve the uniform melting and inflow conditions, to facilitate melting, and to improve the surface and internal quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

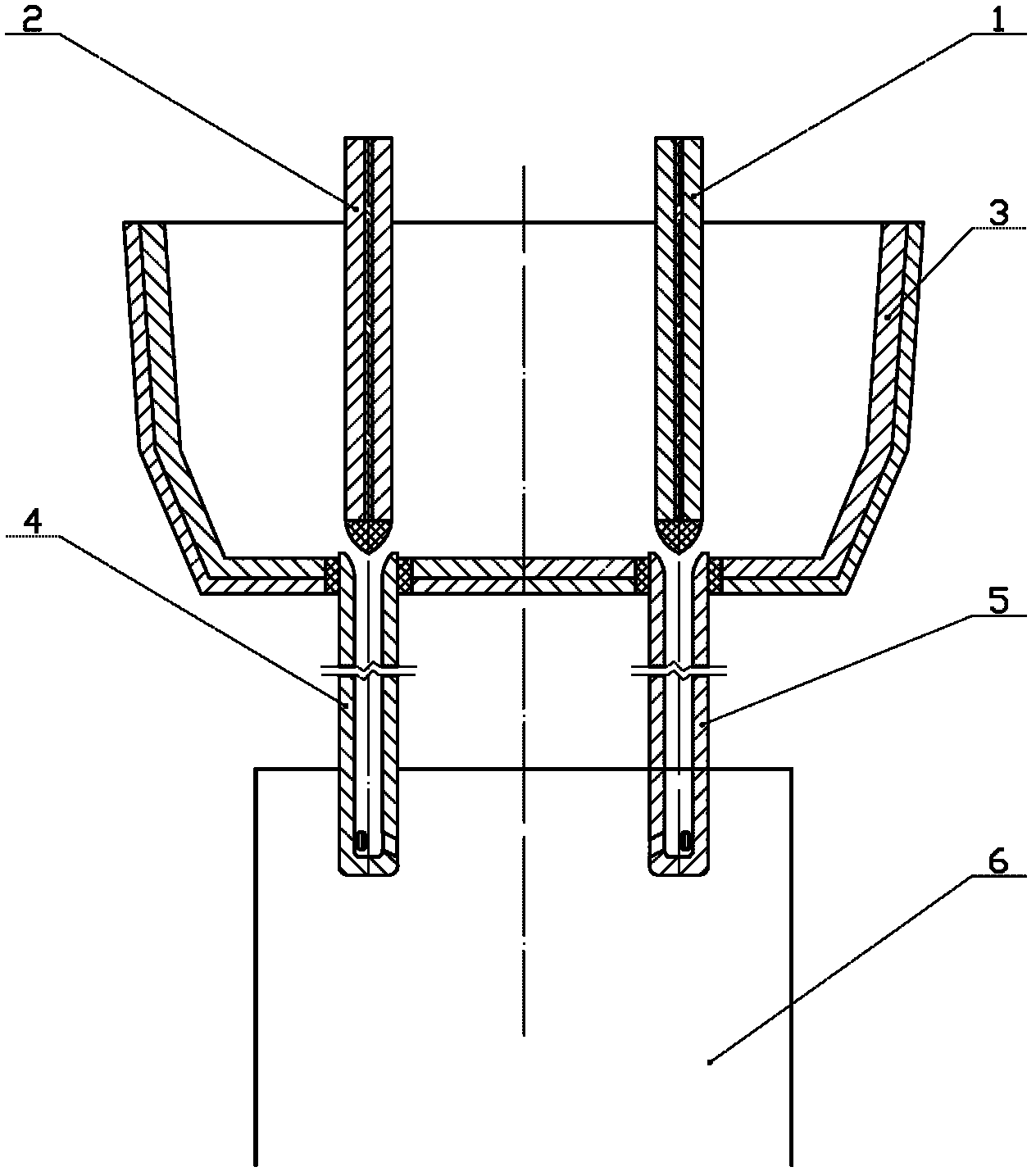

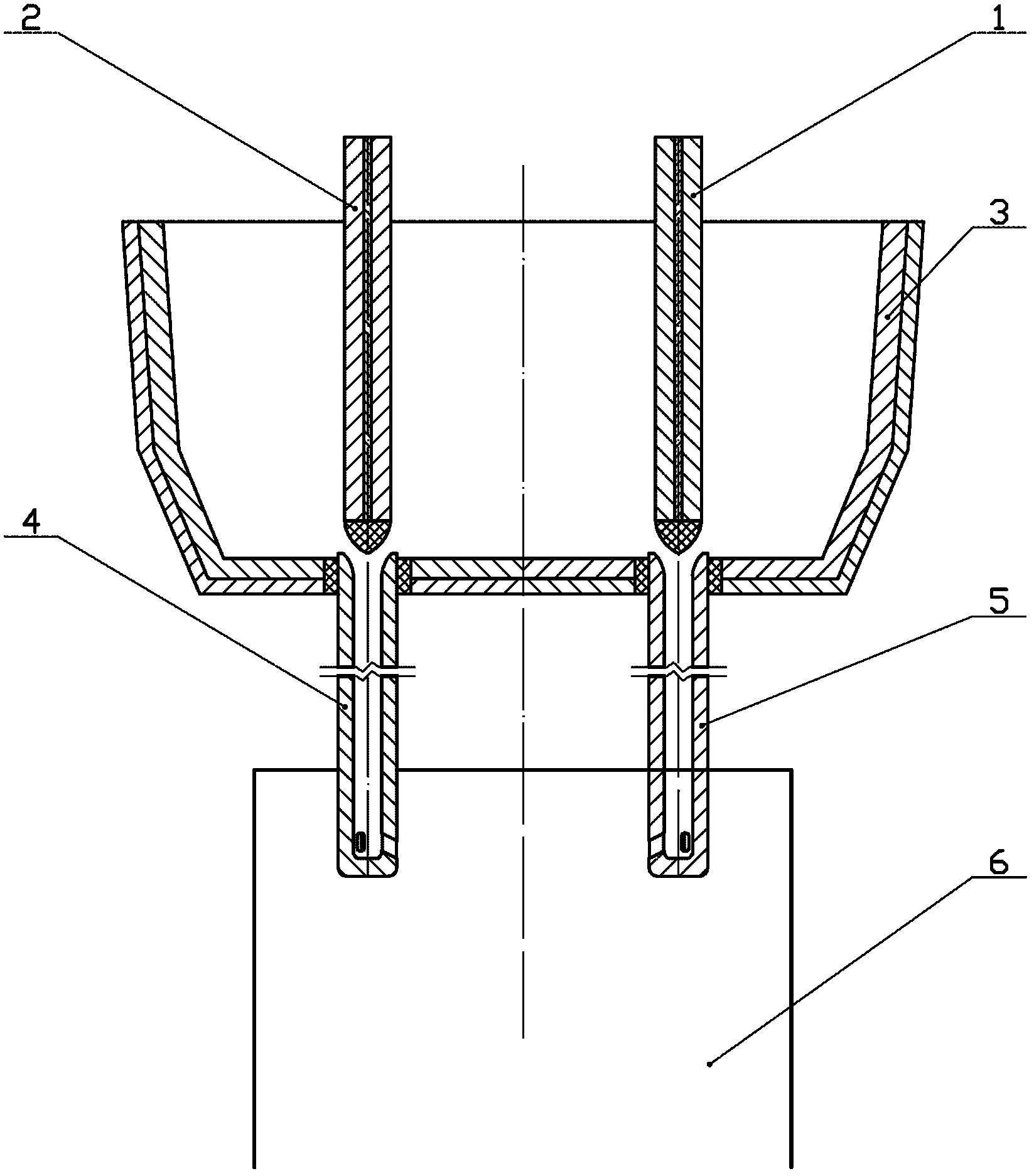

[0034] In the continuous casting method for pouring extra-thick slabs with double nozzles of the present invention, two submerged nozzles (the first submerged nozzle 4 and the second submerged nozzle 5) are vertically inserted into an ultra-thick slab continuous casting crystallizer 6 For pouring, the upper end of each nozzle is connected with the tundish 3 respectively, and the side hole at the lower part of each nozzle is connected with the crystallizer 6, thereby forming two independent passages between the tundish 3 and the crystallizer 6; The molten steel is injected into the crystallizer 6 through two independent passages; a stopper rod (first stopper rod 1 or second stopper rod 2) is used to control the flow of the nozzle above each nozzle in the tundish 3 In order to realize the liquid level control of the crystallizer.

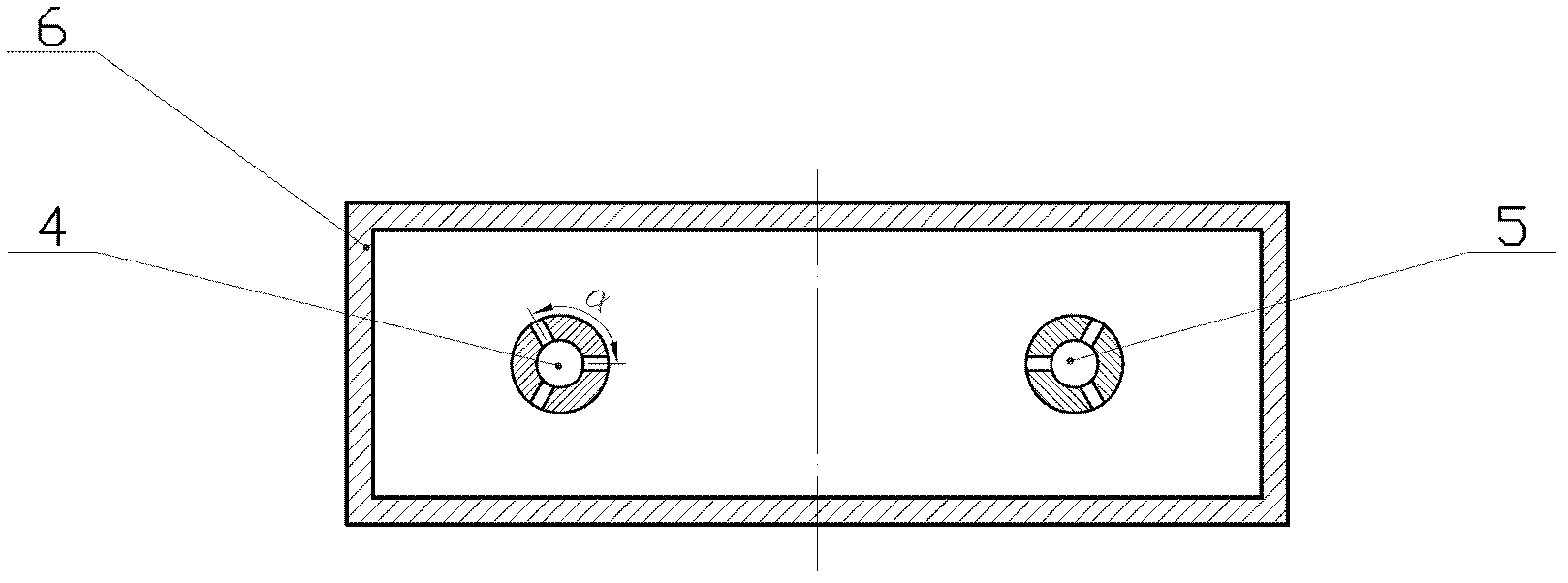

[0035] The two nozzles are arranged on the axis of symmetry between the two wide surfaces of the crystallizer 6, and are axisymmetric to the axis of ...

Embodiment 2

[0042] The continuous casting device for casting extra-thick slabs with double nozzles of the present invention mainly includes: a first stopper 1, a second stopper 2, a tundish 3, a first submerged nozzle 4, a second submerged nozzle 5, and a crystallizer 6; the first submerged nozzle 4 and the second submerged nozzle 5 are vertically inserted into the crystallizer 6, arranged on the axis of symmetry between the two wide faces of the crystallizer 6, and with the symmetry between the two narrow faces The axis is axisymmetric, and the distance between the centers of the circular sections of the two nozzles is 600-1200mm; the upper end of each nozzle is connected to the tundish 3, and the side hole at the lower part of each nozzle is connected to the crystallizer 6, thus in the tundish 3 Two independent channels are formed between the crystallizer and the crystallizer 6; the first stopper rod 1 and the second stopper rod 2 are arranged in the tundish 3, and a stopper rod is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com