Optical measurement method and optical measurement device for five-degree-of-freedom rotation errors of spindle

A technology of rotation error and optical measurement, applied in measurement devices, optical devices, instruments, etc., can solve the problems of complex calculation model, complex structure, nonlinearity, etc., and achieve high CCD resolution, low implementation cost, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

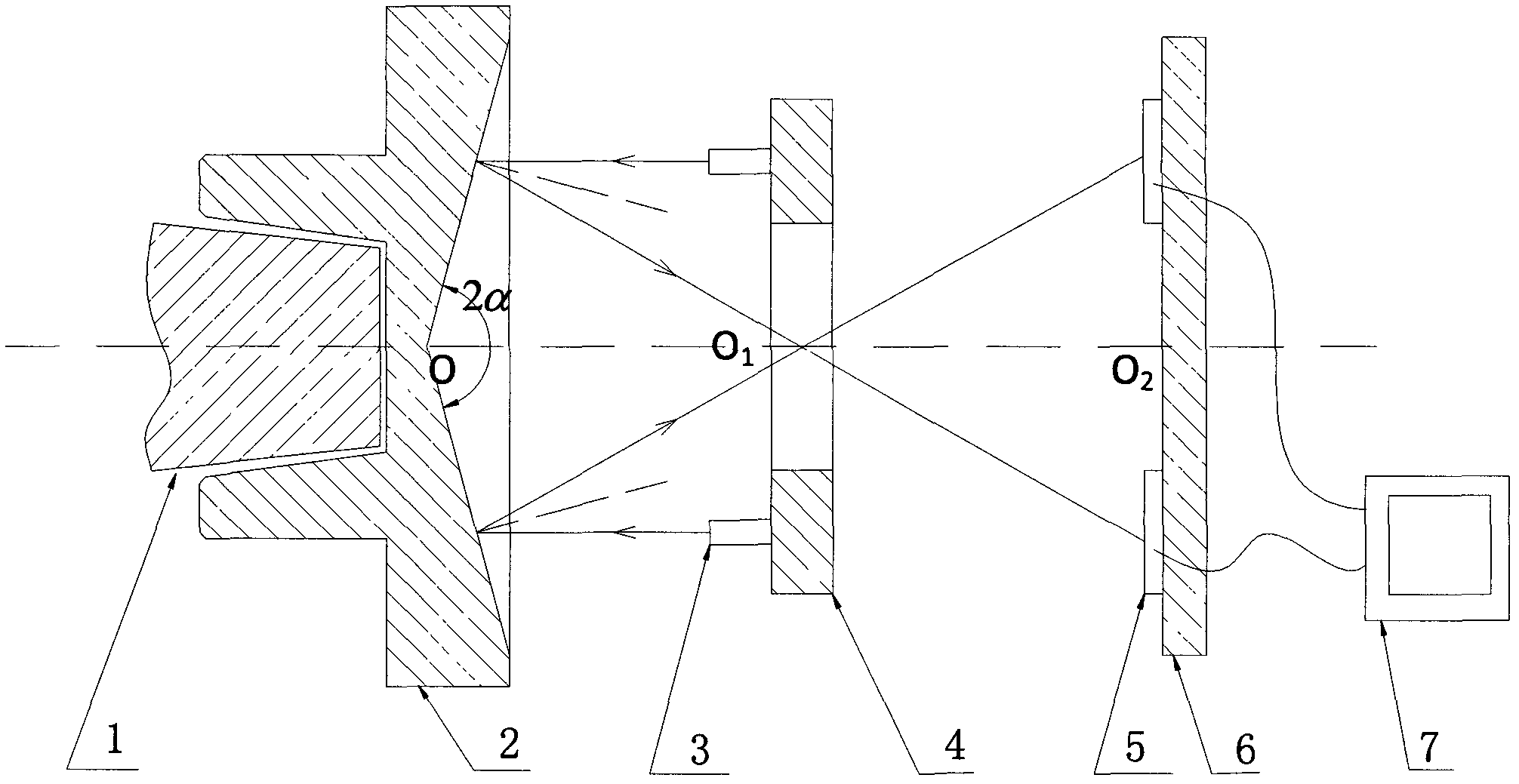

[0025] Such as figure 1 As shown, the present invention installs the flange 2 at the axial end of the main shaft 1 under test, and outside the concave conical reflective surface outside the flange 2, there are four laser generators 3 and four CCDs 5 in sequence and are installed on the respective supports. Arranged alternately, four CCDs 5, the measured spindle 1, flange 2, laser generator support 4 and CCD support 6 are coaxially arranged, and the laser generator support 4 and CCD support 6 can measure the distance in the axial direction. For fine tuning, four CCDs 5 are connected with computer 7 respectively.

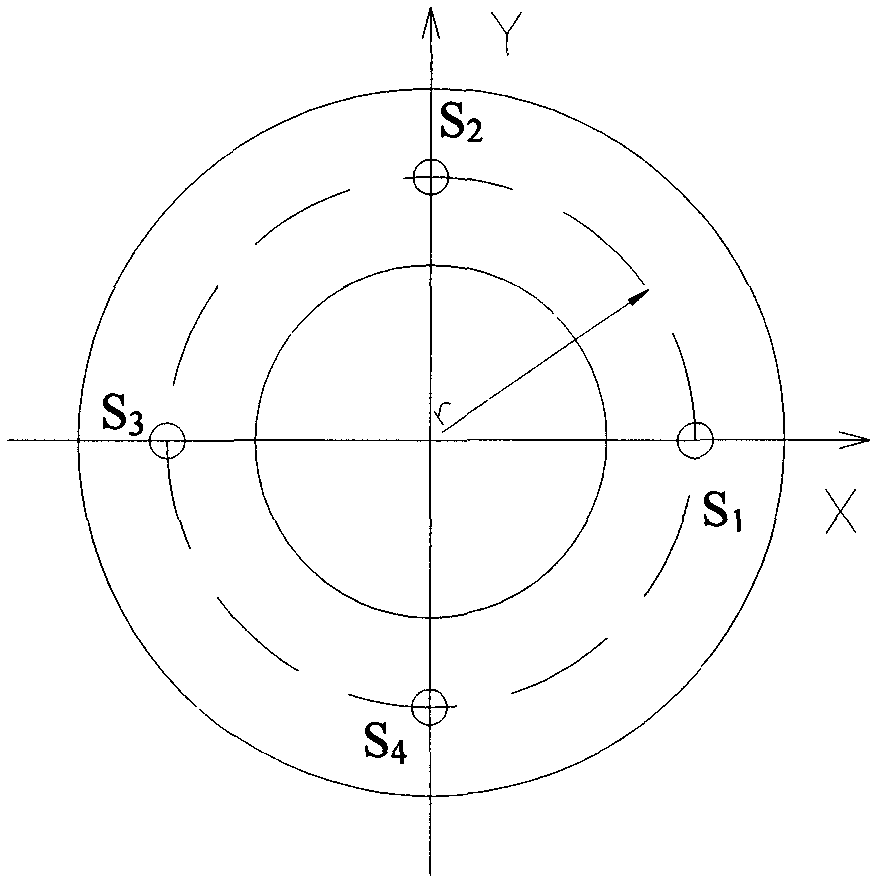

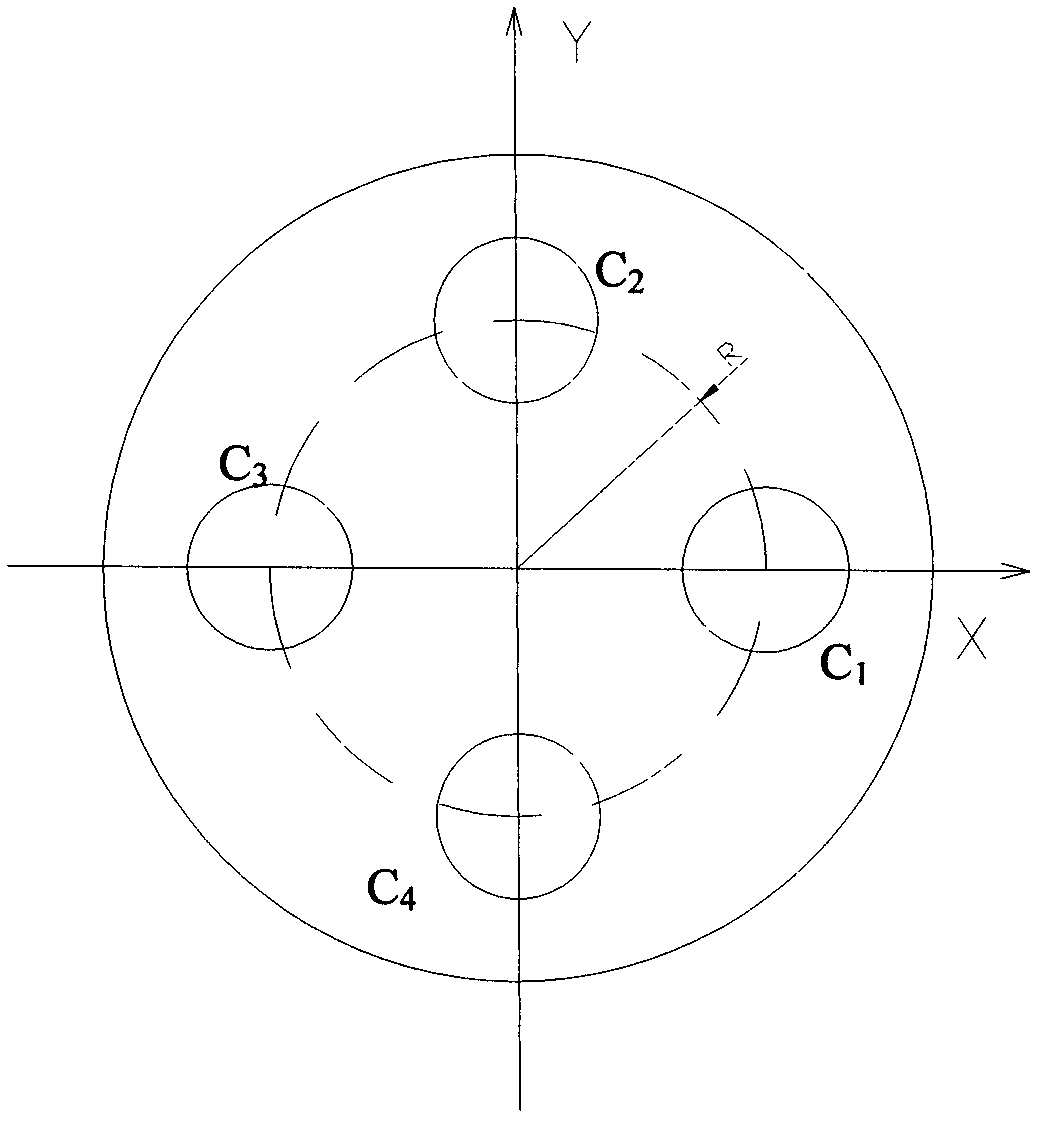

[0026] Among the four laser generators, the axes of the two point laser generators arranged diagonally on the X plane and the axes of the two CCDs arranged diagonally on the X plane among the four CCDs are in the same plane; the four laser generators The axe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com