Method for measuring second-grade river-crossing leveling height difference by using intelligent total station

A total station and height difference technology, which is used in measurement devices, height/level measurement, instruments, etc., can solve the problems of cumbersome measurement operations, difficult to guarantee accuracy, and long detours, so as to achieve a simple measurement operation process and improve accuracy. , the effect of offsetting the atmospheric refraction difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

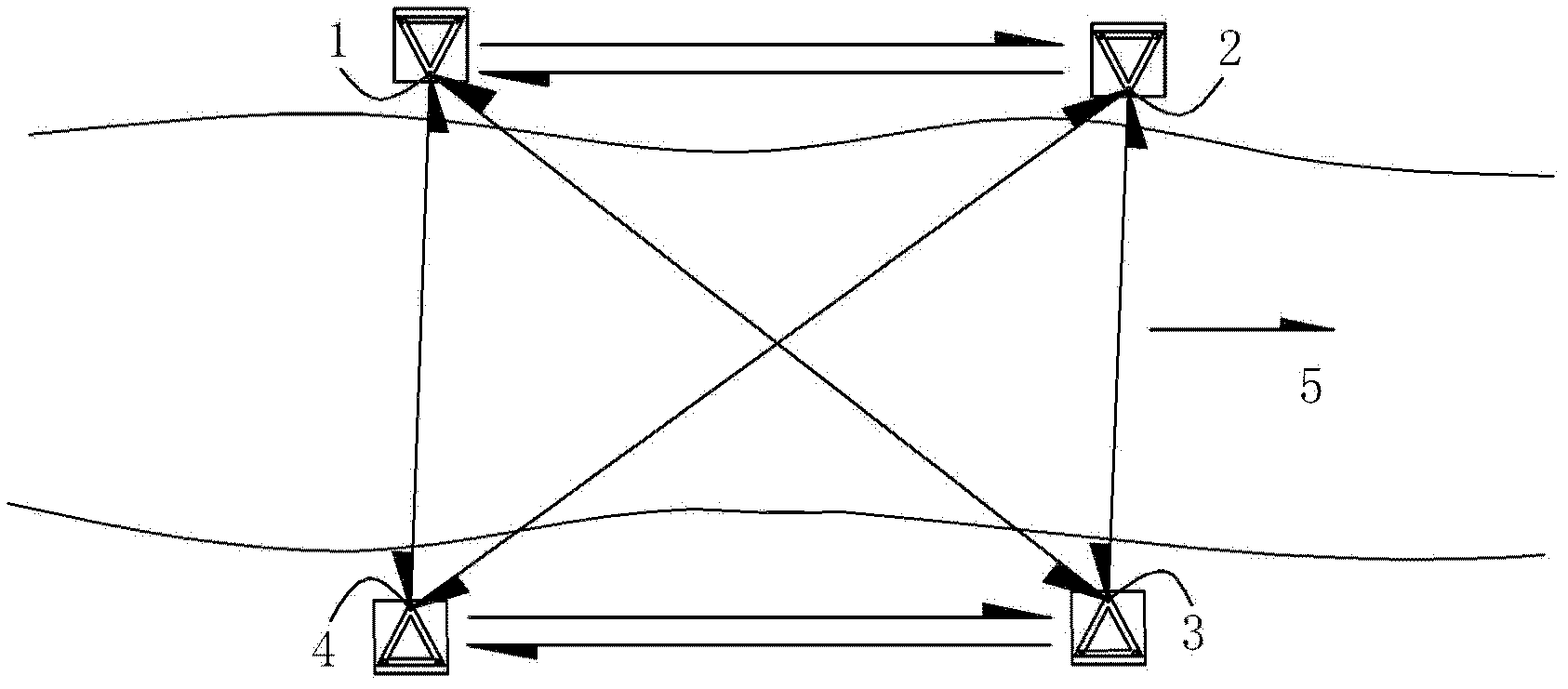

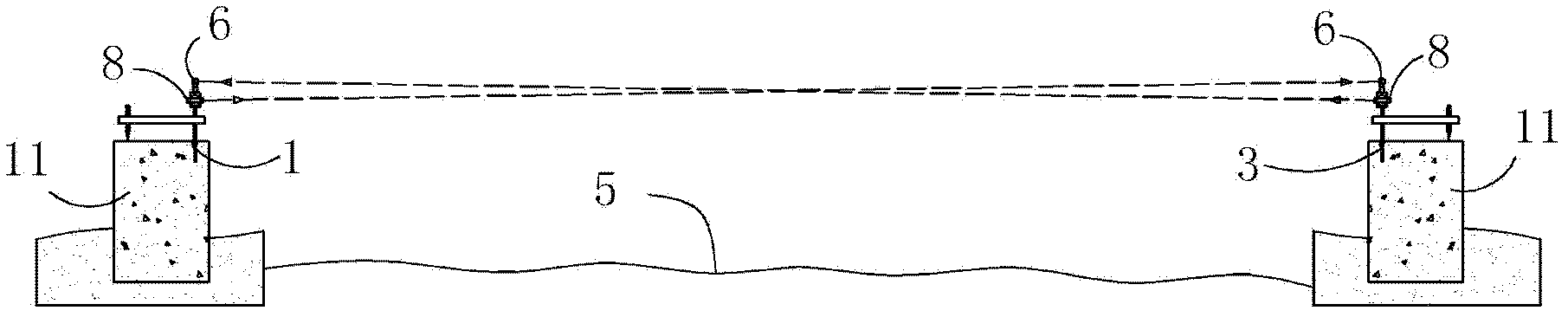

[0026] see figure 1 , figure 2 and image 3 , the method for utilizing the intelligent total station in the present embodiment to measure the second-class cross-river level difference is to proceed as follows:

[0027] a. Set the cross-river benchmarks

[0028] On the river 5, each benchmarking point is set with the two banks of the crossed river section as the cross-river benchmarking point area, and each benchmarking point includes: the first benchmarking point 1 and the second benchmarking point located on one bank of the river and 1-5m away from the bank 2. The distance between the first benchmarking point 1 and the second benchmarking point 2 is 80-120m; and the third benchmarking point 3 and Fourth Benchmark 4.

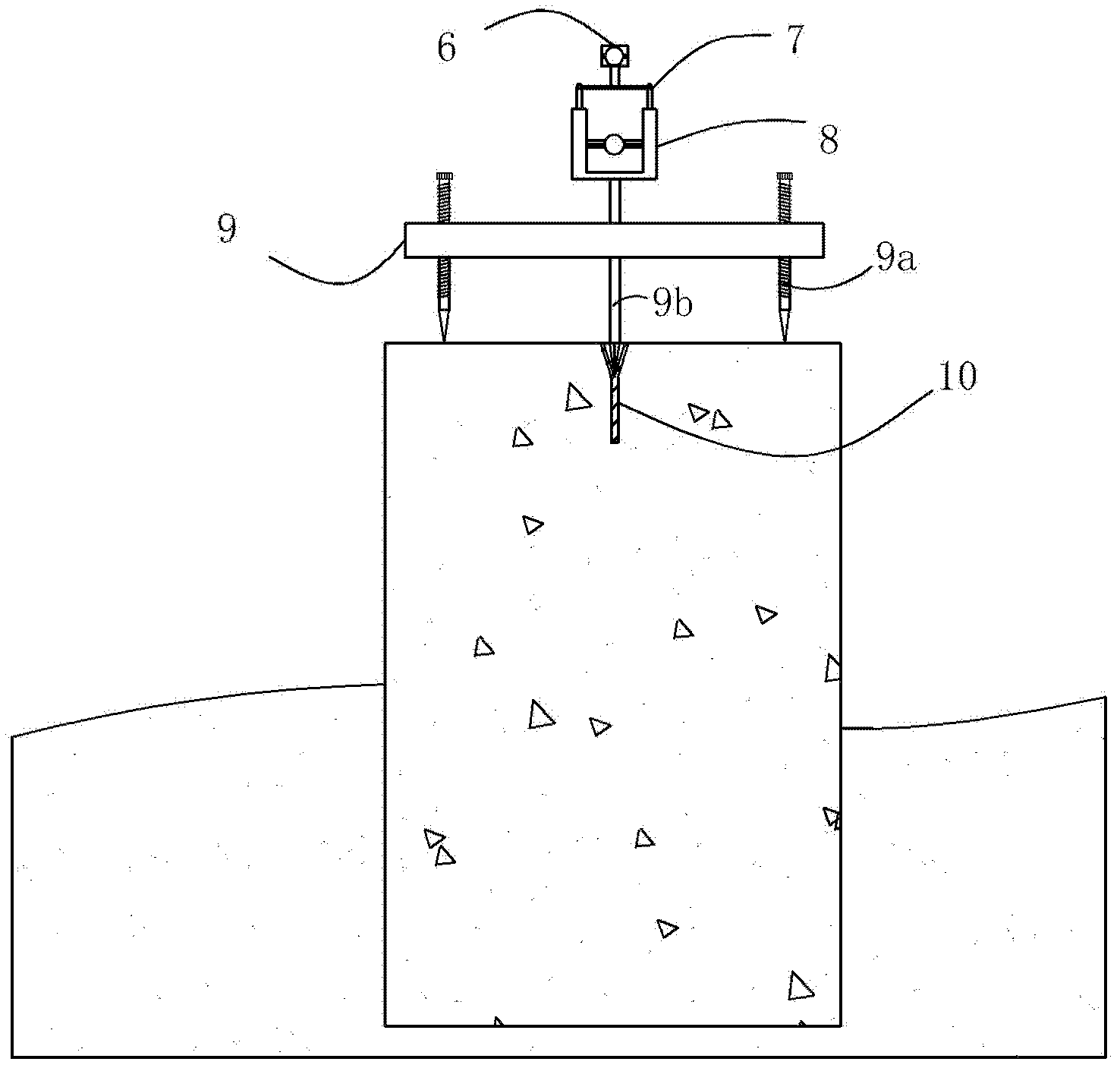

[0029] The setting of each benchmarking point: Observation pier 11 is respectively arranged at the position of each benchmarking point, and a benchmarking point base 10 with cone socket is buried on the top surface of observation pier 11, and the centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com