Vibration monitoring and diagnosing device based on oil film thickness

A vibration monitoring and diagnosis device technology, applied in the field of measurement, can solve problems such as blade fracture and fatigue cracks in rotating parts, and achieve the effects of high sampling accuracy and sampling rate, fast calculation speed, and large storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

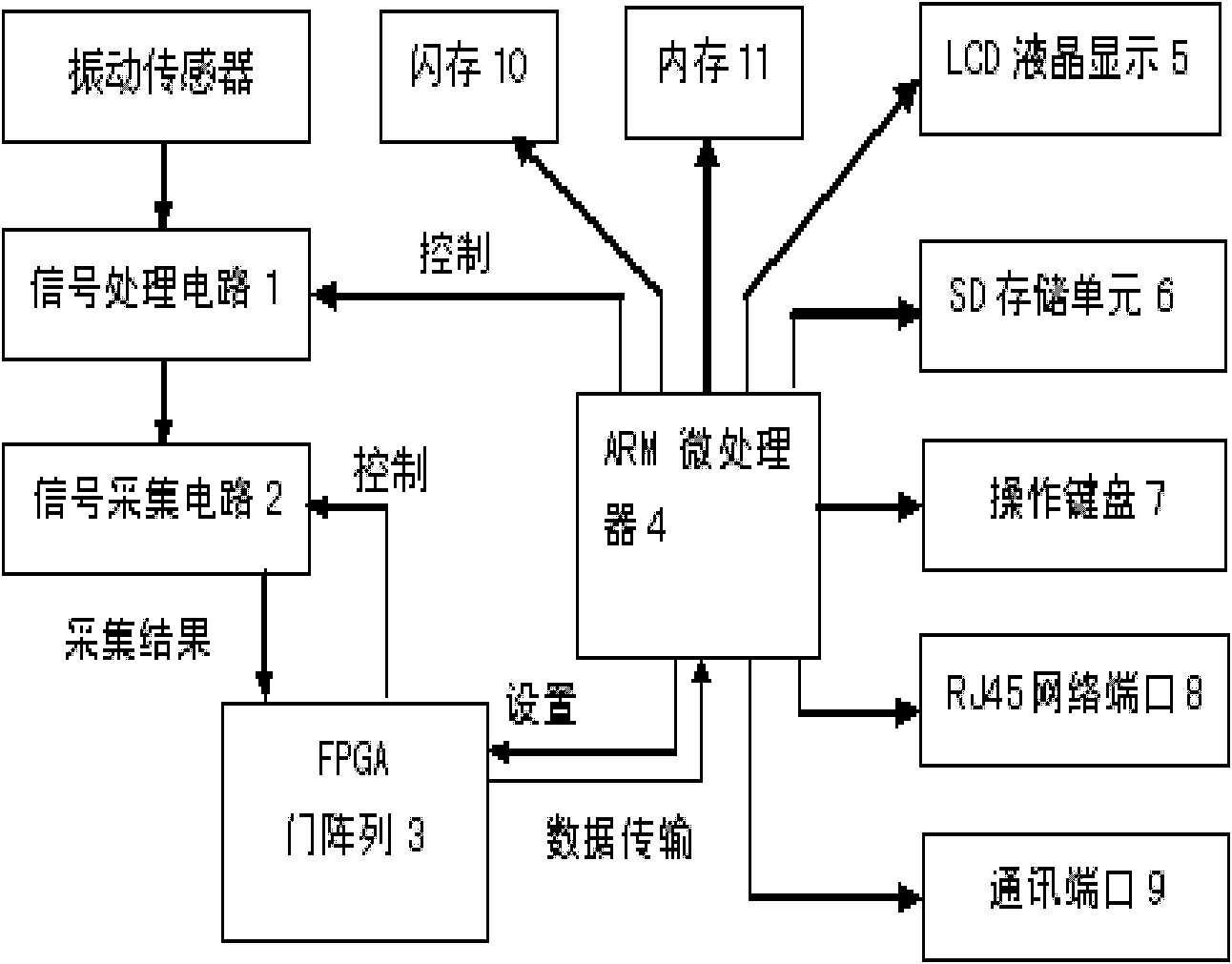

[0039] refer to figure 1 , The vibration monitoring and diagnosis device based on oil film thickness of the present invention includes signal processing circuit 1, signal acquisition circuit 2, FPGA gate array 3, ARM microprocessor 4, LCD liquid crystal display 5, SD storage unit 6, operation keyboard 7, RJ45 network Port 8, communication port 9, FLASH flash memory 10 and RAM memory 11. It can realize online monitoring of oil film thickness, shaft vibration amplitude and pad vibration amplitude and comprehensive fault diagnosis of counter-rotating machine vibration state.

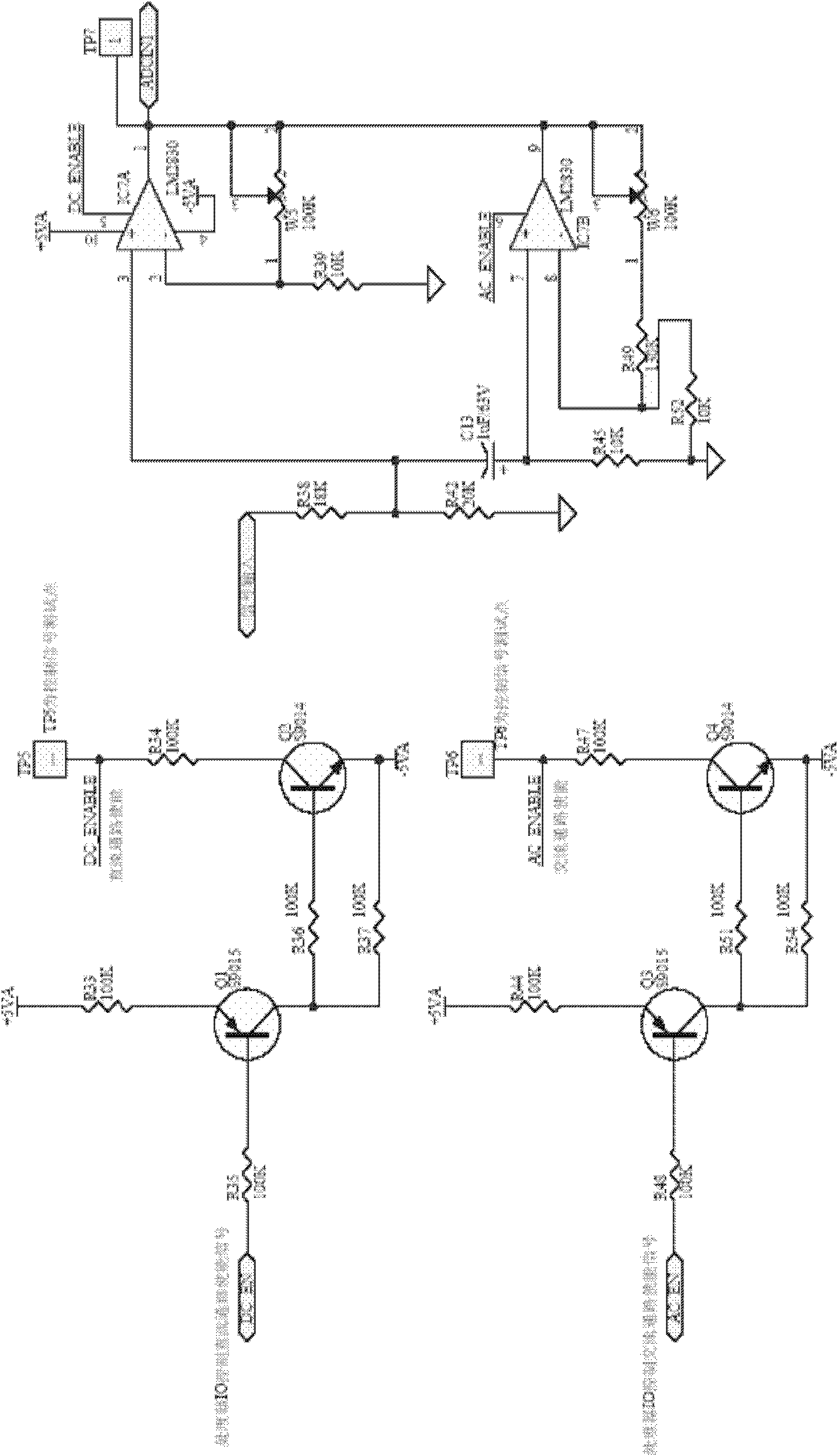

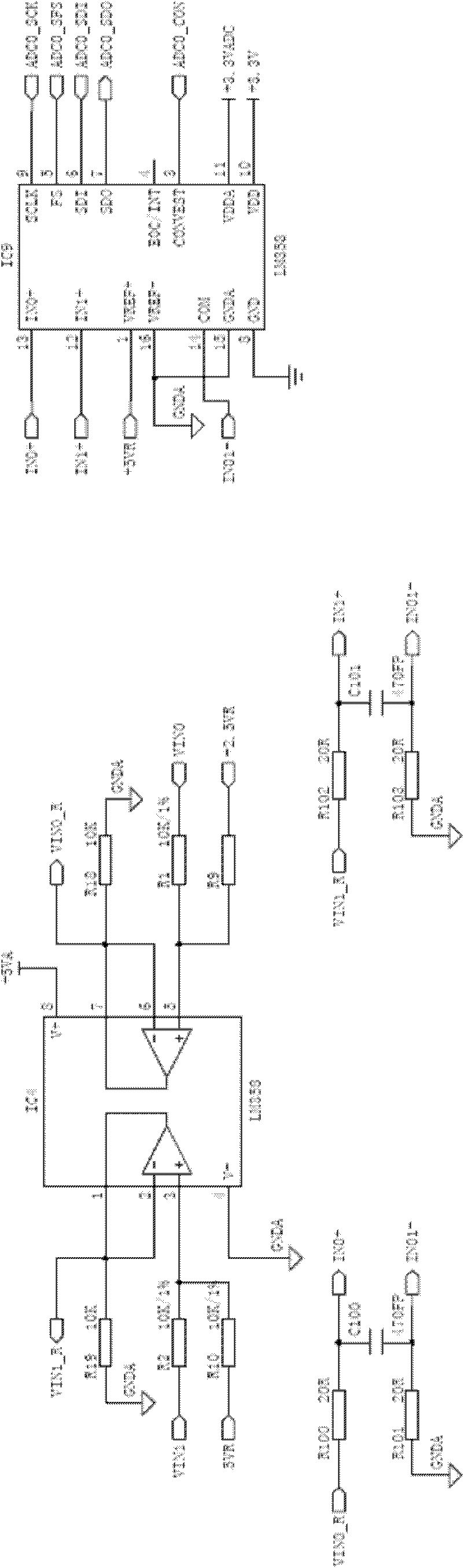

[0040] refer to figure 1 with 2, the signal processing circuit 1 can simultaneously process eight channels of vibration sensor signals, and complete the AC-DC switching output of the required sensor signals. Take the single channel as an example, including model LM2830 chip IC7, model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com