Method for sampling ultrahigh flow aerosol and sampler

A sampler and aerosol technology, applied in the direction of sampling devices, etc., can solve the problems that the sampling volume cannot meet the requirements, it is difficult to change the sampling location, the volume and weight of the sampler are large, etc., and it is convenient for flow measurement and concentration calculation. Location, effect of reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

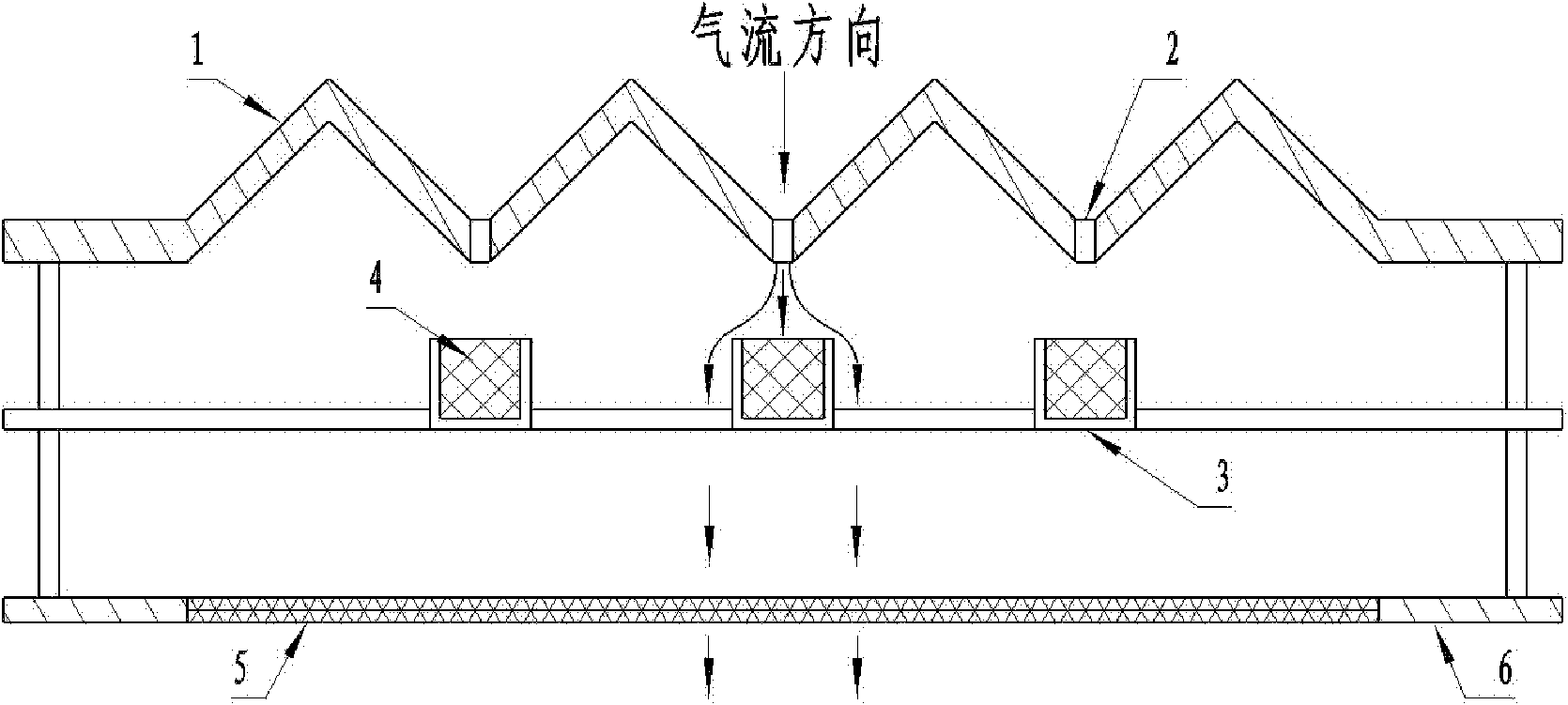

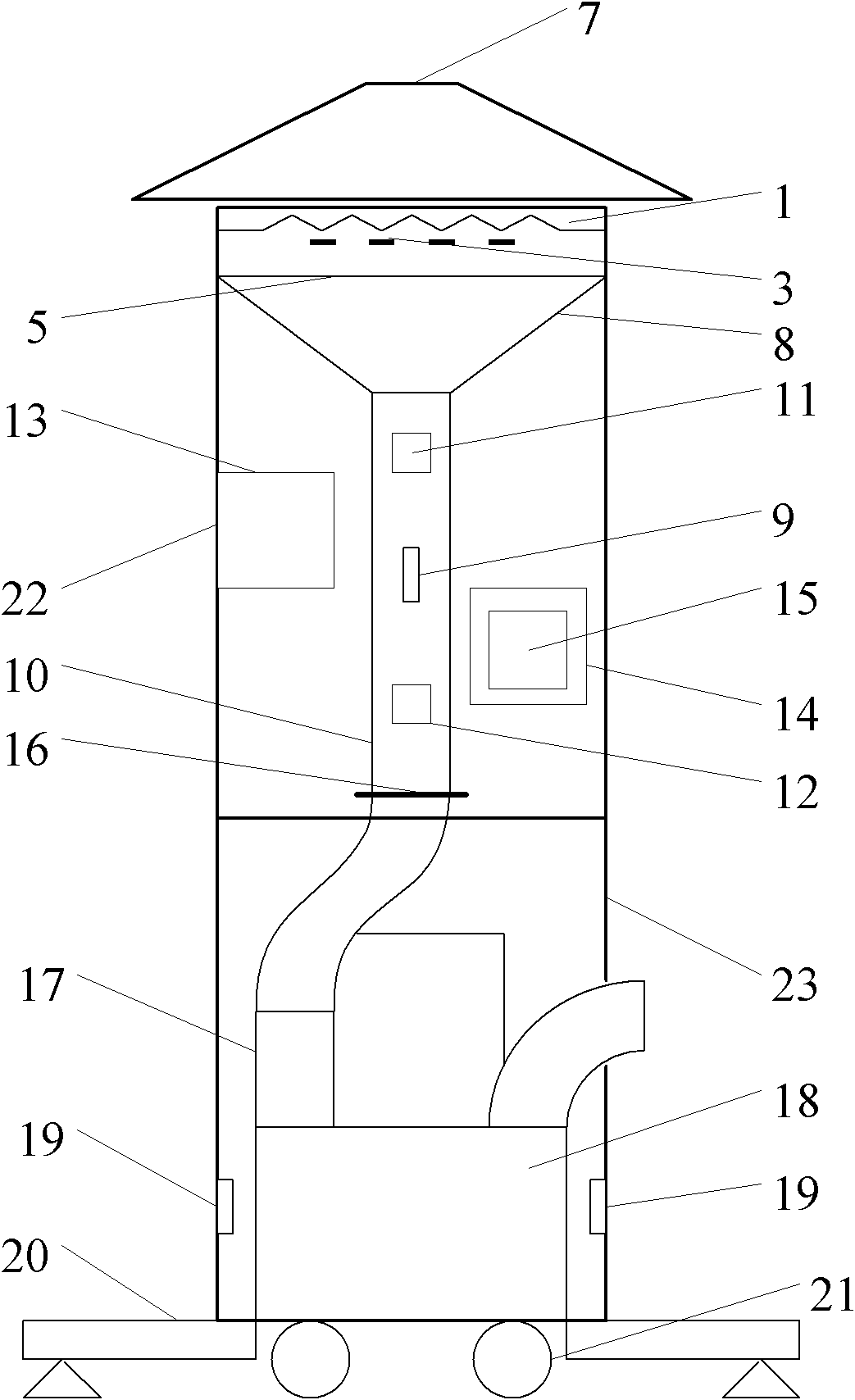

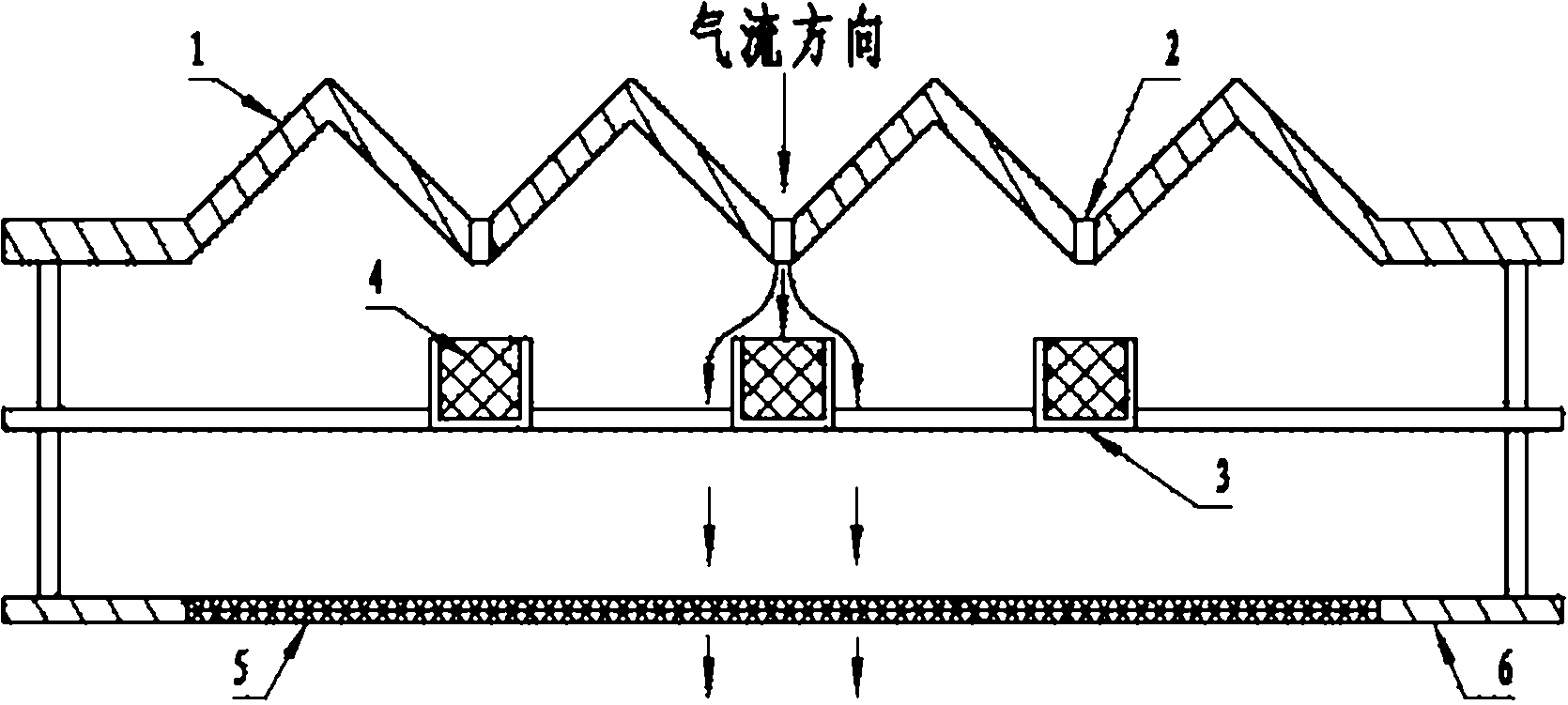

[0027] Such as figure 1 and figure 2 As shown, the main body of the ultra-aerosol sampler includes the wind cap 7, the sampling pipeline box 22 and the power box 23. All three parts can be disassembled, and can be used as a sampler when integrated, and can be disassembled when transported. Air cap 7 is assembled for four boards, can be disassembled when needed and is convenient to transport. The hood 7 is located directly above the sampling pipeline box 22, and is connected with the sampling pipeline box 22 with sleeve-type bolts. There are loose-leaf and locking mechanisms at the top of the bolts. The four sides of the sampling pipeline box 22 are detachable, which is convenient. For transportation and maintenance, the air inlet of the sampling pipeline box 22 is provided with an impactor, and the impactor includes a wave-shaped upper plate 1 and a plurality of collection tanks 3 with built-in non-woven fabrics 4 arranged under the upper plate 1, for non-woven fabrics To c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com