Upper end cover assembly of flexible strapdown gyroscope

A cover assembly, gyro technology, applied in the direction of electric assemblies, electrical components, chassis/cover/support, etc., can solve the problem of reducing the size of the gyro, the distance between the gyro motor and the signal device, the torque device, the electromagnetic interference of the motor and the heat generation The signal device has a large influence, so as to reduce the assembly workload, reduce the volume, and facilitate the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

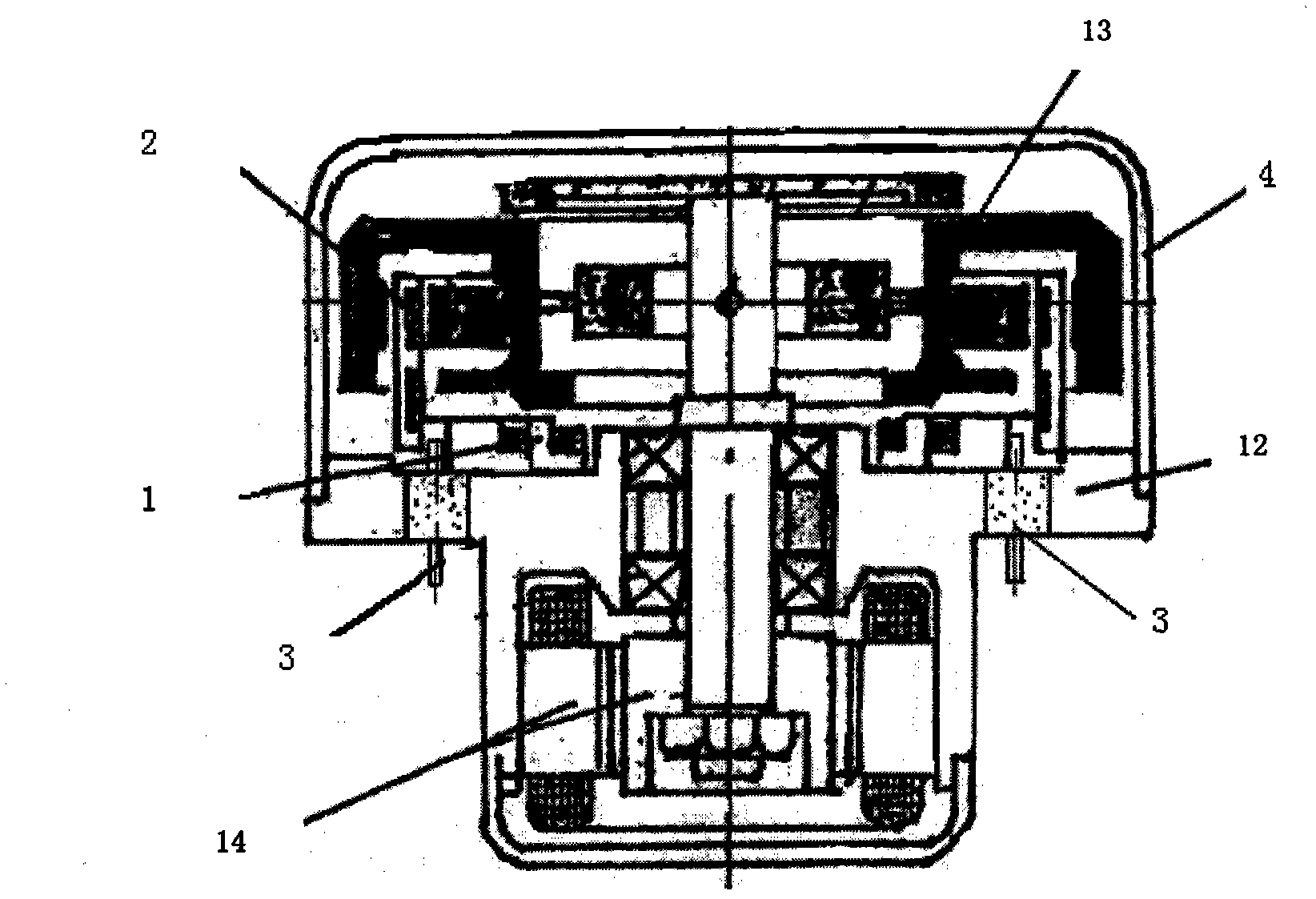

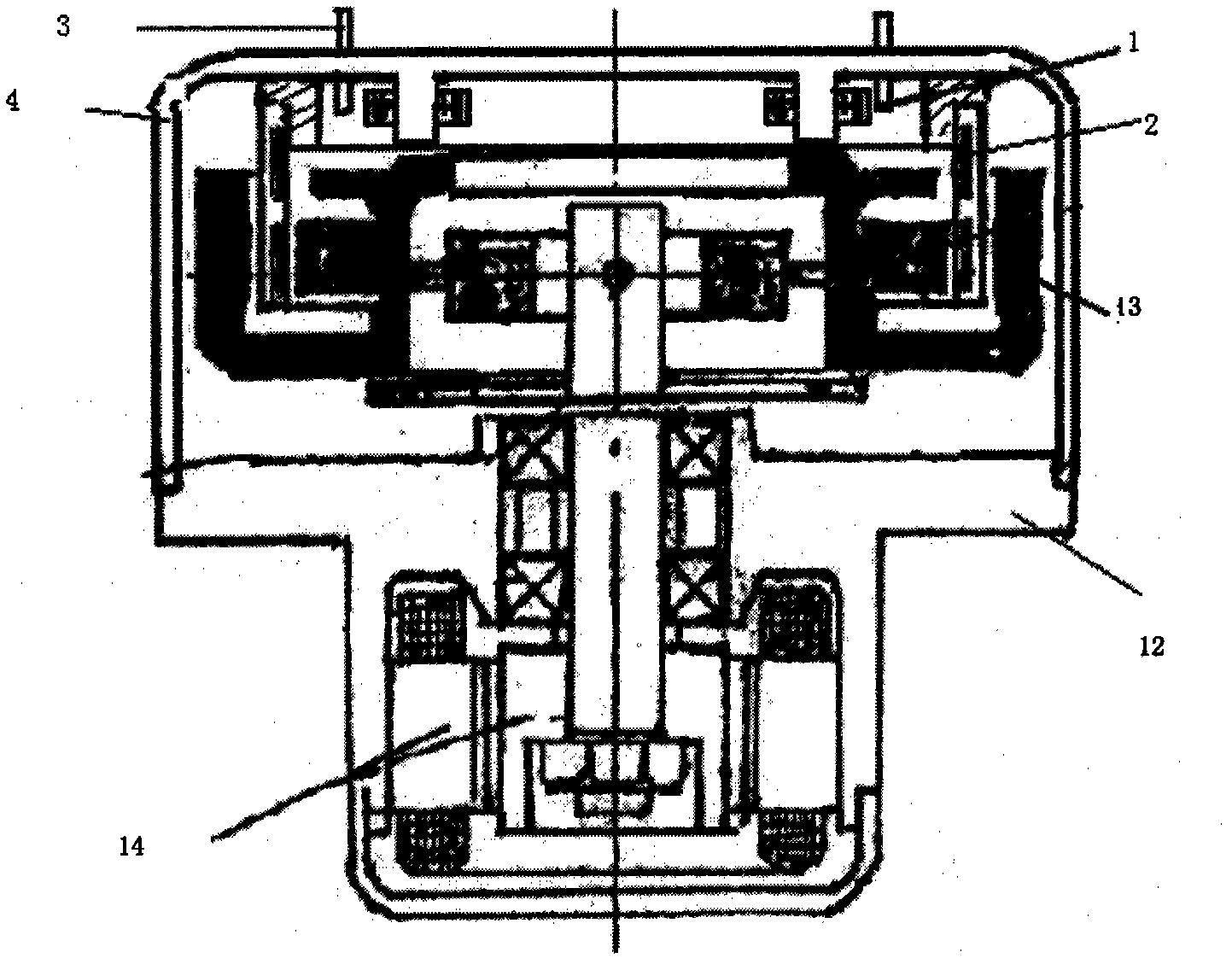

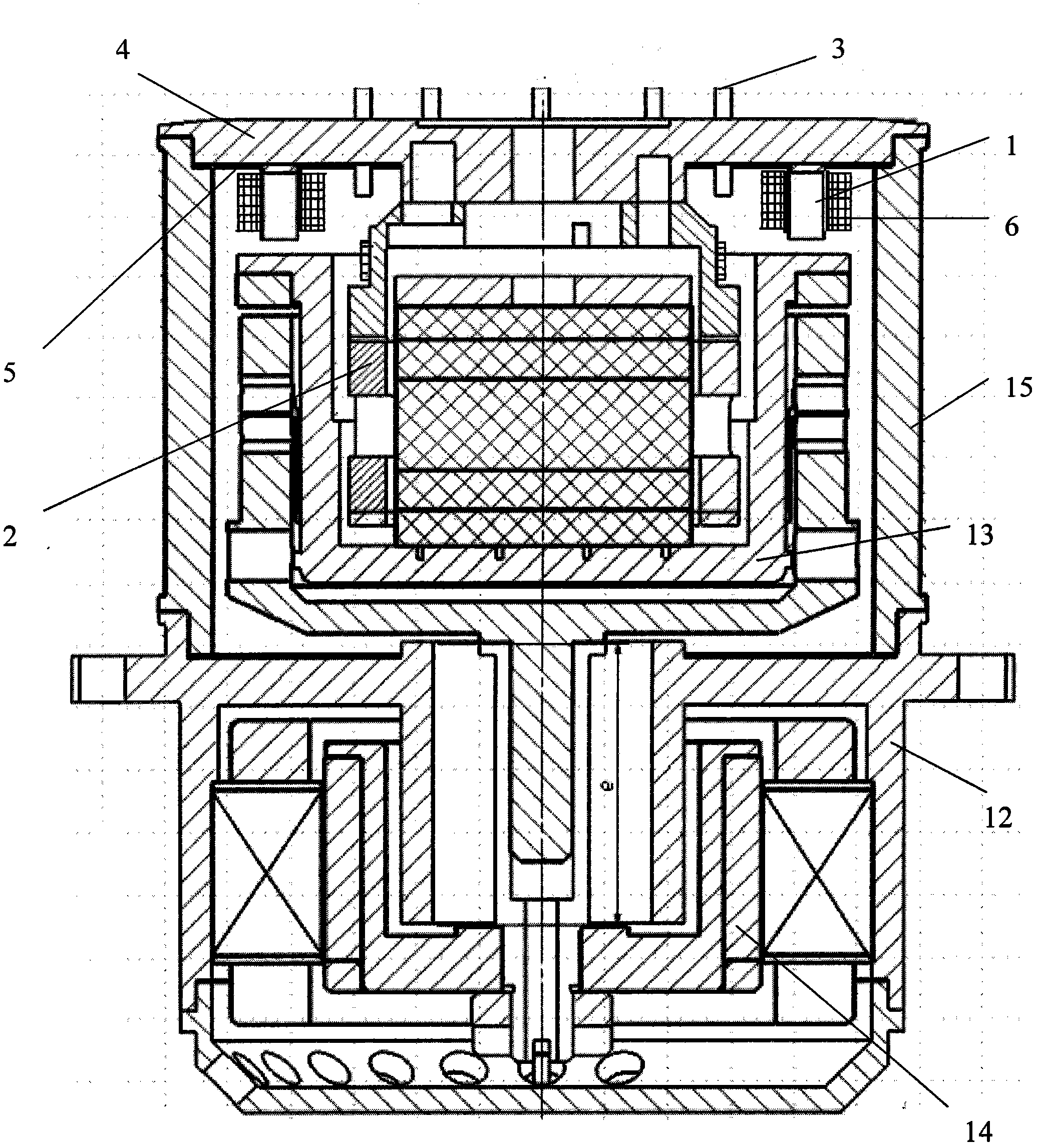

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as image 3 As shown, a flexible strapdown gyroscope upper end cover assembly includes four sets of signaler cores 1, torquer stator assembly 2, 12 insulators 3, upper end cover 4, and film cable 5. It is characterized in that four sets of U-shaped The signaler core 1 is evenly distributed on the outer ring circumference of the inner plane of the upper end cover 4, and is fixedly connected with the upper end cover 4 of the gyro as a whole and directly processed and formed. The upper end surface of the rotor 13 is used as the armature of the signaler, and the eight signaler coils 6 are sequentially formed. Set at both ends of four sets of U-shaped signal generator cores 1; 12 insulators 3 are evenly sintered in the middle of two adjacent groups of signal device cores 1 in groups of three, serving as the lead wires of signal device coil 6 and torque device coil 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com