Method for producing and processing preform, preform and optical fiber

A technology for prefabricated parts and optical fibers, applied in the field of optical fibers, can solve problems such as cost increase, and achieve the effects of good processing reliability, cost reduction, and processing reliability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

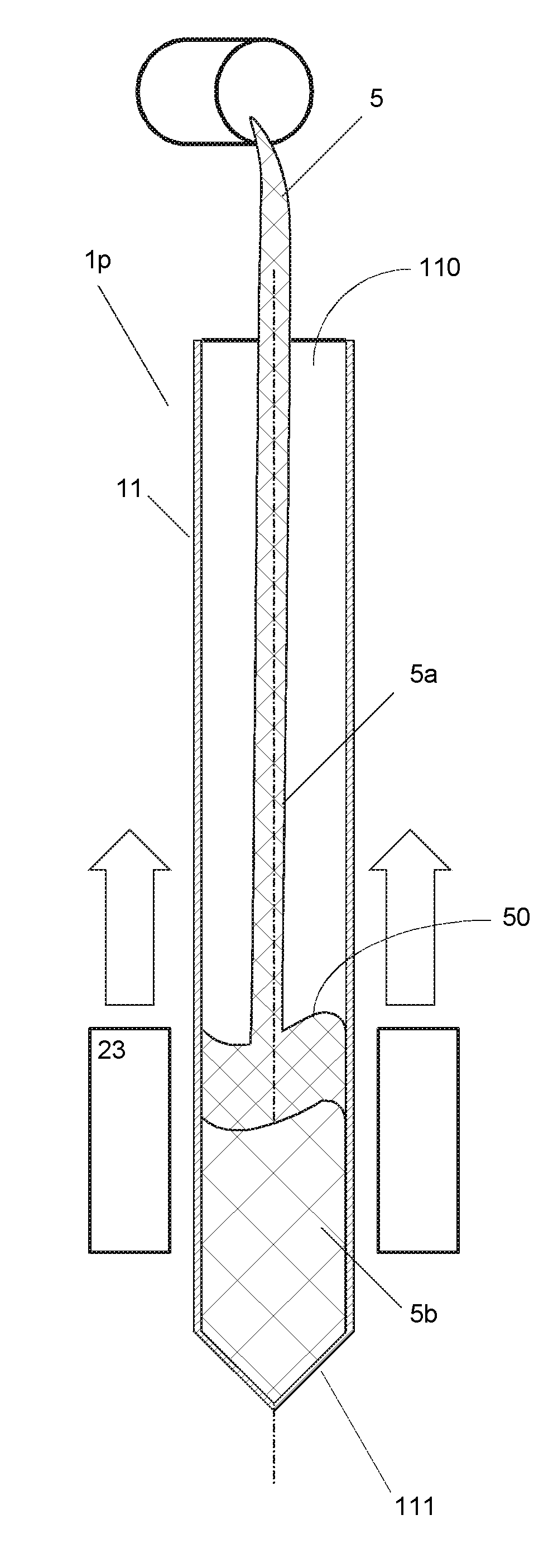

[0055] Figure 1a shows the SiO 2 Manufactured thin-walled quartz tube 11 having a main axis x, an inner space 110 and a conical closure 111 at its lower end. The diameter d10 of the wall of the quartz tube 11 is very small compared to the diameter of the quartz tube 11 so that a relatively larger part of the preform will comprise high quality silica particles.

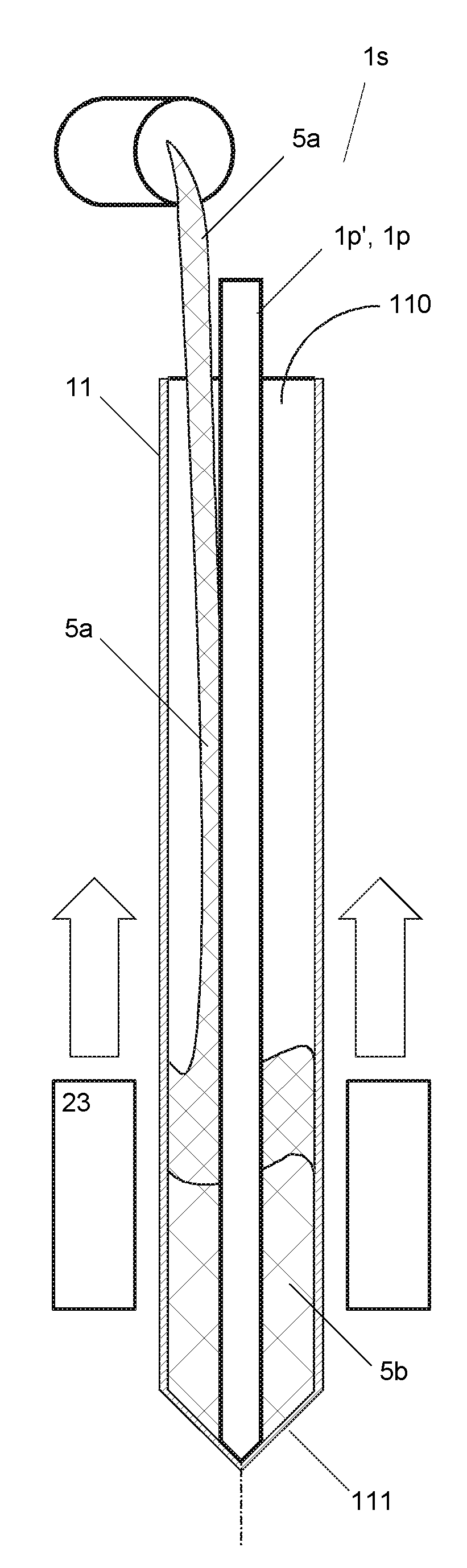

[0056] Fig. 1b shows the quartz tube 11 of Fig. 1a, wherein the inner space 110 is completely filled with silica particles 5 to obtain a raw primary preform 1p'. As shown in Figure 1b, the filling process was not accompanied by the heating process.

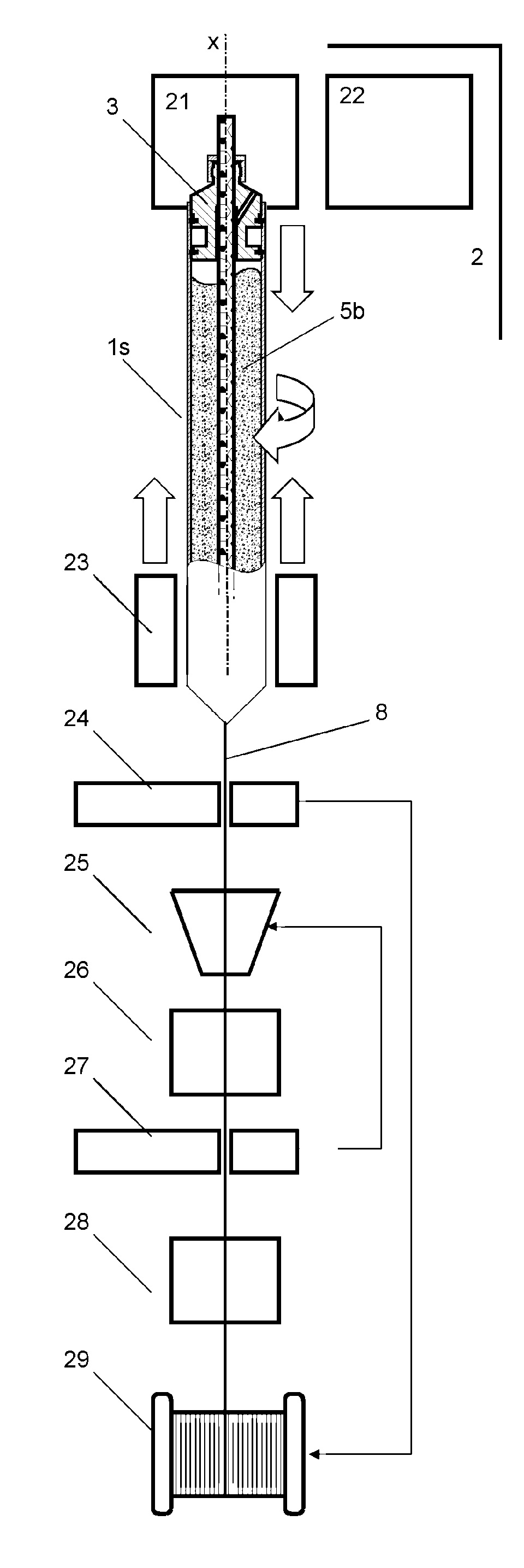

[0057] Fig. 1c shows the raw primary preform 1p' of Fig. 1b being closed by means of an abutment 3. The abutment 3 comprises a first channel 31 and a second channel 32 . A first channel 31 designed to optionally receive a primary preform 1p', 1p or a glass blank is closed by a cover 4. The second channel 32 is connected to a vacuum pump 22 which evacuates the quartz tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com