Independent-aeration high-voltage pulse discharging water treatment reactor and sewage treatment method thereof

A high-voltage pulse discharge and reactor technology, applied in the field of ion technology in the field of environmental pollution control, can solve the problems of insufficient ozone utilization, fragile film, unfavorable separation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

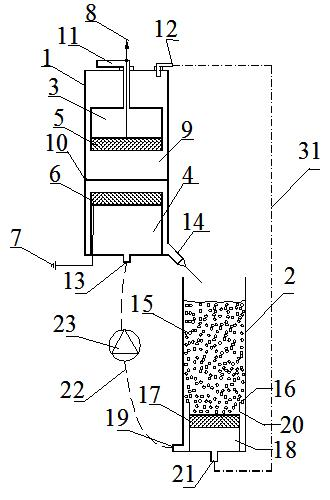

[0034] Such asfigure 1 As shown, an independent aeration high-voltage pulse discharge water treatment reactor includes a high-voltage pulse discharge reaction device 1 and an independent aeration device 2 lower than the high-voltage pulse discharge reaction device. The high-voltage pulse discharge reaction device includes an upper The gas chamber 3 and the lower liquid chamber 4, the gas chamber 3 is embedded with an upper porous titanium plate 5 as a high-voltage electrode, and the liquid chamber is embedded with a lower porous titanium plate 6 as a ground electrode, and the high-voltage electrode is passed through a high-voltage wire 8 is connected to a high-voltage power supply, the ground electrode is connected to the ground wire 7 through a wire, the polarity of the high-voltage electrode and the ground electrode can be reversed, and the part between the upper porous titanium plate electrode and the lower porous titanium plate is a discharge area 9 , the top of the high-vo...

Embodiment 2

[0047] The high-voltage pulse discharge reaction device and the independent aeration device in this embodiment are basically the same as those in Embodiment 1, the difference is that in this embodiment, a multi-stage reactor is formed by changing the connection mode of the pipelines in the device.

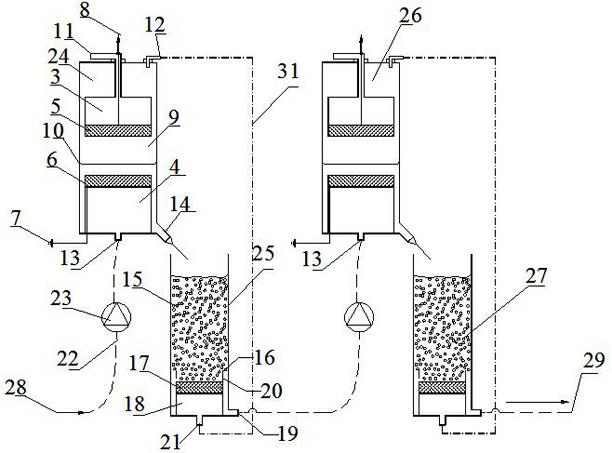

[0048] Such as figure 2 As shown, the reactor in this embodiment is a multi-stage reactor composed of at least two sets of the above-mentioned high-voltage pulse discharge reaction devices and independent aeration devices. The aeration device 25, the lower-level high-voltage pulse discharge reaction device 26, and the lower-level independent aeration device 27, wherein the liquid inlet on the uppermost high-voltage pulse discharge reaction device and the external water source 28 are communicated through a silica gel conduit 22, and the silica gel conduit 22 is provided with There is a peristaltic pump 23, and the liquid is pumped by the peristaltic pump. The liquid outlet 19 of th...

Embodiment 3

[0062] The high-voltage pulse discharge reaction device and independent aeration device in this embodiment are basically the same as in Example 1, the difference is that this embodiment includes one of the above-mentioned high-voltage pulse discharge reaction devices and at least two independent aeration devices, and changes the device The connection method of the pipeline.

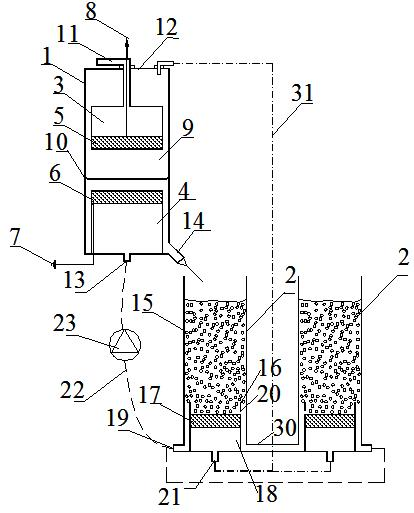

[0063] Such as image 3 As shown, the reactor includes one of the above-mentioned high-voltage pulse discharge reaction devices and at least two independent aeration devices, and the liquid outlets 19 of the independent aeration devices are connected to each other and connected to the liquid inlet 13 of the high-voltage pulse discharge reaction device. It communicates with the silica gel conduit 22, and the silica gel conduit 22 is provided with a peristaltic pump 23. The aeration inlets 21 of the independent aeration devices communicate with each other and communicate with the gas outlet 12 of the high-v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com