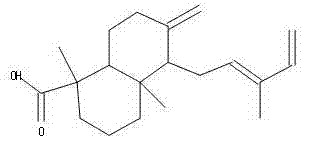

Method for extracting carboxylic acid from juniperus chinensis

A technology of cypress acid and cypress, applied in the preparation field of extracting cypress acid from plants, achieving the effects of less pollution, large-scale production operations, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get cypress bark 10Kg, pulverize, add to CO 2 In the supercritical extractor, ethanol is used as the entrainer, the entrainer accounts for 1% by volume of the total extraction solvent, the extraction pressure is 10MPa, the temperature is 40°C, CO 2 The flow rate is 1ml / g crude drug·min, the extraction time is 80min, and the extract is obtained, which is adsorbed by D101 macroporous adsorption resin, washed with water to remove impurities, eluted with 30% ethanol, collected 3 times the column volume eluate, passed through a 201×7 type Strongly basic styrene-type anion-exchange resin adsorption, eluted with 0.4mol / L NaOH solution, collected and eluted, filtered, passed through 001×7 type strongly acidic styrene-type cation-exchange resin, collected effluent, filtered, Concentrate, add ethyl acetate to crystallize, separate and crystallize, wash and dry to obtain 26.7g of acanthusic acid, which is detected by HPLC with a purity of 95.5%, UV, IR, MS, 2 HNMR, 13 The data c...

Embodiment 2

[0026] Get cypress bark 10Kg, pulverize, add to CO 2 In the supercritical extractor, ethanol is used as the entrainer, the entrainer accounts for 3% by volume of the total extraction solvent, the extraction pressure is 30MPa, the temperature is 50°C, CO 2 The flow rate is 3ml / g crude drug·min, the extraction time is 120min, and the extract is obtained, adsorbed by D101 macroporous adsorption resin, eluted with water to remove impurities, eluted with 50% ethanol, collected 8 times the column volume eluate, passed through a 201×4 type Strongly basic styrene-type anion-exchange resin adsorption, eluted with 0.4mol / L NaOH solution, collected and eluted, filtered, passed through 001×4 strong acidic styrene-type cation-exchange resin, collected effluent, filtered, Concentrate, add ethyl acetate to crystallize, separate and crystallize, wash and dry to obtain 28.9g of acanthusic acid, detected by HPLC, the purity is 93.4%, UV, IR, MS, 2 HNMR, 13 The data characterizing its physical...

Embodiment 3

[0028] Get cypress bark 10Kg, pulverize, add to CO 2 In a supercritical extractor, ethanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 2%, the extraction pressure is 20MPa, the temperature is 45°C, CO 2 The flow rate is 2ml / g crude drug·min, the extraction time is 100min, and the extract is obtained, which is adsorbed by D101 macroporous adsorption resin, washed with water to remove impurities, eluted with 40% ethanol, collected 5 times the column volume eluate, passed through D201 strong base Adsorbed with a strong styrene-type anion exchange resin, eluted with 0.4mol / L NaOH solution, collected and eluted, filtered, passed through a D001 type strongly acidic styrene-type cation-exchange resin, collected the effluent, filtered, concentrated, and added acetic acid Ethyl ester was crystallized, separated and crystallized, washed, and dried to obtain 24.2 g of cinnamon acid, which was detected by HPLC with a purity of 97....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com