Strontium-silicon alterative for hypereutectic AlSi alloy

A technology of aluminum-silicon alloy and modifier, which is applied in the field of strontium-silicon modifier, can solve the problems of splitting matrix continuity, restricting the application range of hypereutectic aluminum-silicon alloy, deteriorating the comprehensive mechanical properties and cutting performance of the alloy, and achieving The modification effect is stable, the environmental pollution is small, and the effect of improving the performance of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

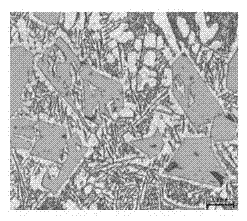

[0016] Example 1: (1) The mass percent composition of the modificator is silicon: 80%, strontium: 20%. Compact under a pressure of 1KN; (2) Put the briquette into the rapid heating furnace, and make the rapid heating furnace heat up from room temperature to 1500°C in 30 minutes, keep it warm for 60 minutes, and cool it with the furnace; (3) Put the silicon prepared in step 2 - Strontium alloy crushing, ball milling, the ball milling particle size is 200 mesh; (4) The ball milled Si-Sr modifier is heat treated at 1000°C, and the obtained modifier is Si and Si 2 Mixture of Sr.

Embodiment 2

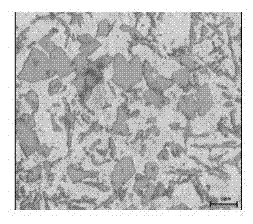

[0017] Example 2: (1) The mass percent composition of the modificator is silicon: 57.2%, strontium: 42.8%. Compact under a pressure of 1KN; (2) Put the briquette into the rapid heating furnace, and make the rapid heating furnace heat up from room temperature to 1500°C in 30 minutes, keep it warm for 60 minutes, and cool it with the furnace; (3) Put the silicon prepared in step 2 - The strontium alloy is crushed and ball milled with a particle size of 200 mesh. (4) The ball-milled Si-Sr modifier is heat-treated at 1045°C, and the obtained modifiers are SiSr and Si 2 Mixture of Sr.

Embodiment 3

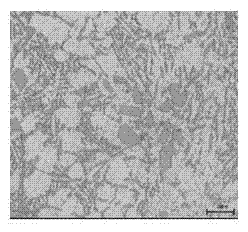

[0018] Example 3: (1) The mass percent composition of the modificator is silicon: 11.5%, strontium: 88.5%. Compact under a pressure of 1KN; (2) Put the briquette into the rapid heating furnace, and make the rapid heating furnace heat up from room temperature to 1500°C in 30 minutes, keep it warm for 60 minutes, and cool it with the furnace; (3) Put the silicon prepared in step 2 - Crushing and ball milling of strontium alloy, the particle size of the ball mill is 200 mesh; (4) Heat treatment of the ball-milled Si-Sr modifier at 700°C, and the obtained modifiers are Sr and SiSr 2 mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com