Method for observing metallographic structure of niobium-titanium alloy

A technology of metallographic structure and niobium-titanium alloy is applied in the field of observation of metallographic structure of niobium-titanium alloy, which can solve the problems of difficult to obtain a clear structure of niobium-titanium alloy metallographic samples, achieve easy operation, reduce corrosion amount, reduce Possible effects of erosion pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

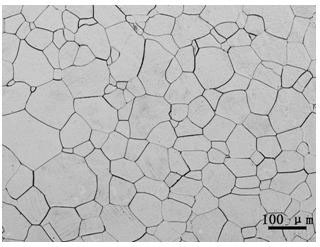

Embodiment 1

[0022] Metallographic structure observation method of 10mm×10mm niobium-titanium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed off the sand grains, and the ground sample is polished on the polishing machine first, with a volume ratio of H 2 SO 4 : HNO 3 : HF=4:1:1 solution to chemically polish the sample, polish for 3s, and finally use a volume ratio of H 2 SO 4 : HNO 3 :HF:HCl=1:1:1:0.5 solution erosion for 10s.

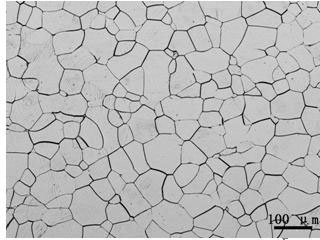

Embodiment 2

[0024] Metallographic structure observation method of 10mm×10mm niobium-titanium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed off the sand grains, and the ground sample is polished on the polishing machine first, with a volume ratio of H 2 SO 4 : HNO 3 : HF=5:1:1 solution to chemically polish the sample, polish for 4s, and finally use a volume ratio of H 2 SO 4 : HNO 3 :HF:HCl=2:1.5:1.5:0.5 solution erosion for 15s.

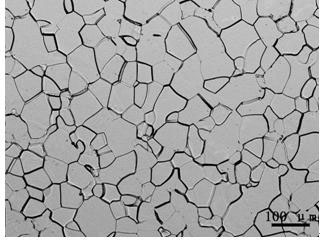

Embodiment 3

[0026] Metallographic structure observation method of 10mm×10mm niobium-titanium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed off the sand grains, and the ground sample is polished on the polishing machine first, with a volume ratio of H 2 SO 4 : HNO 3 : HF=5:2:2 solution to chemically polish the sample, polish for 5s, and finally use a volume ratio of H 2 SO 4 : HNO 3 :HF:HCl=1:1:1:1 solution erosion for 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com