Lens module and portable electronic device using same

A lens module and lens barrel technology, applied in installation, television, electrical components, etc., can solve problems such as unfavorable miniaturization and large thickness of camera devices, and achieve the effects of avoiding electromagnetic interference, reducing volume, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

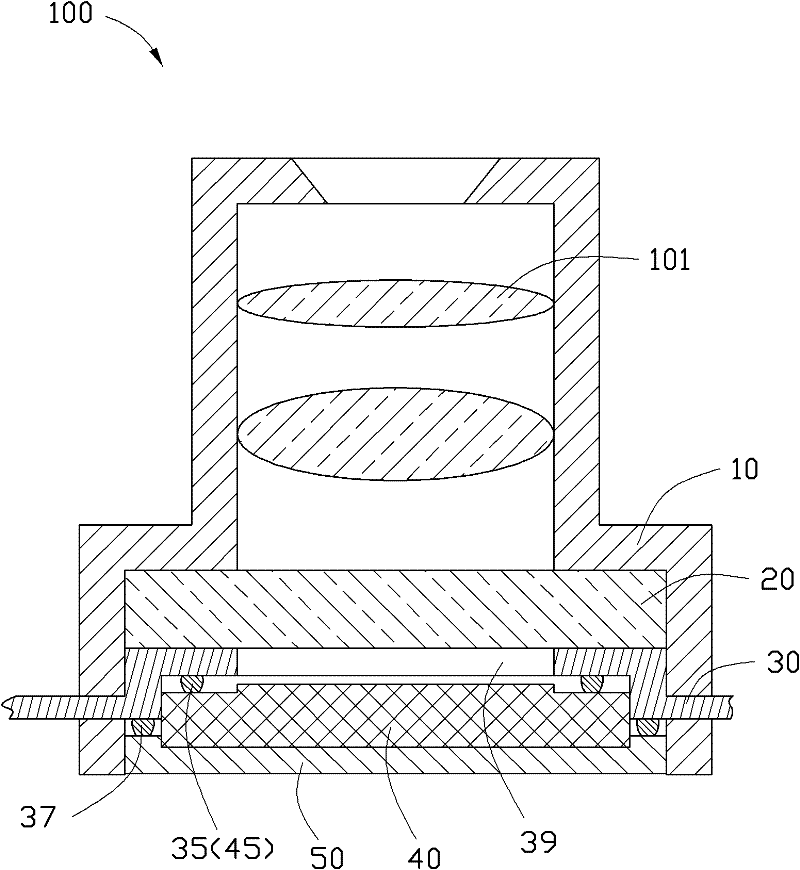

[0054] see Figure 4 , the second embodiment of the present invention provides a lens module 200 . The lens module 200 is basically the same as the lens module 100 of the first embodiment, except that one end of the flexible circuit board 30a protrudes from the bottom of the lens barrel 10a, and the edge of the other end of the flexible circuit board 30a is in contact with the lens barrel. The inside of the lens barrel 10a abuts against and is accommodated in the second receiving cavity 13a, so that there is no need to open a through hole 15 on the lens barrel 10a for the flexible circuit board 30a to pass through.

no. 3 approach

[0056] see Figure 5 and Figure 6 , the third embodiment of the present invention provides a lens module 300 . The lens module 300 is basically the same as the lens module 200 of the second embodiment, except that a pivot shaft 17b and a locking hole 19b are provided at the bottom of the lens barrel 10b, and the pivot shaft 17b connects from the lens barrel 10b extends from the bottom. The electromagnetic shielding cover 50b includes a bottom portion 51b and a plurality of side portions 53b connected in succession, and the cross section of the side portion 53b along the direction of the optical axis L is trapezoidal. Two protrusions 55b are arranged on the top surface of the side part 53b, and pivot holes 550b are correspondingly opened on the two protrusions 55b. It is pivotally connected with the lens barrel 10b and can rotate relative to the lens barrel 10b. An elastic hook 19b is provided on the top surface of the side part 53b opposite to the pivot shaft 17b, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com