Light emitting semiconductor device with complementary electrode layer and manufacturing method thereof

A technology of light-emitting semiconductor and electrode layer, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of easy electrode loss of chips, and achieve the effect of avoiding electrode loss, improving utilization rate and reducing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

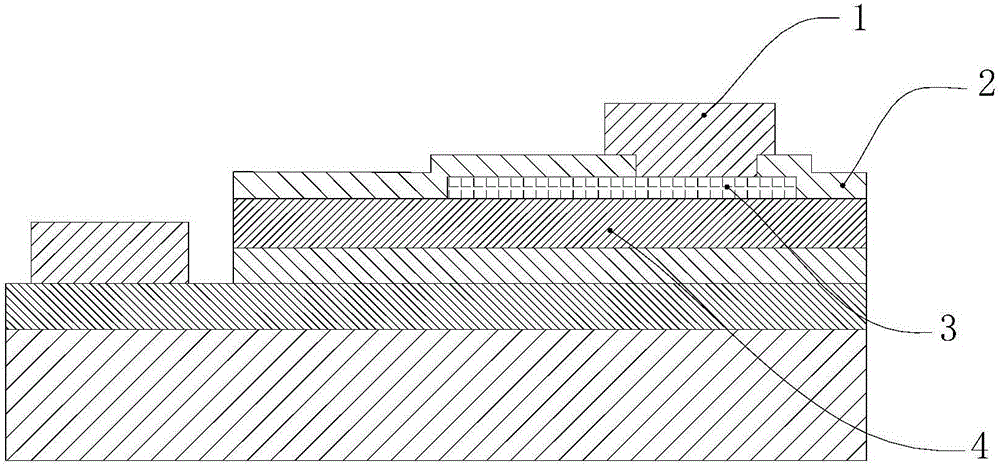

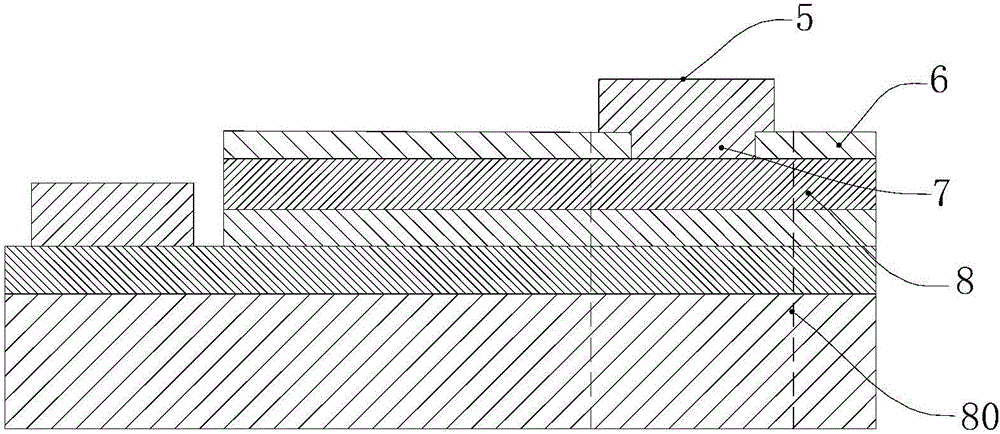

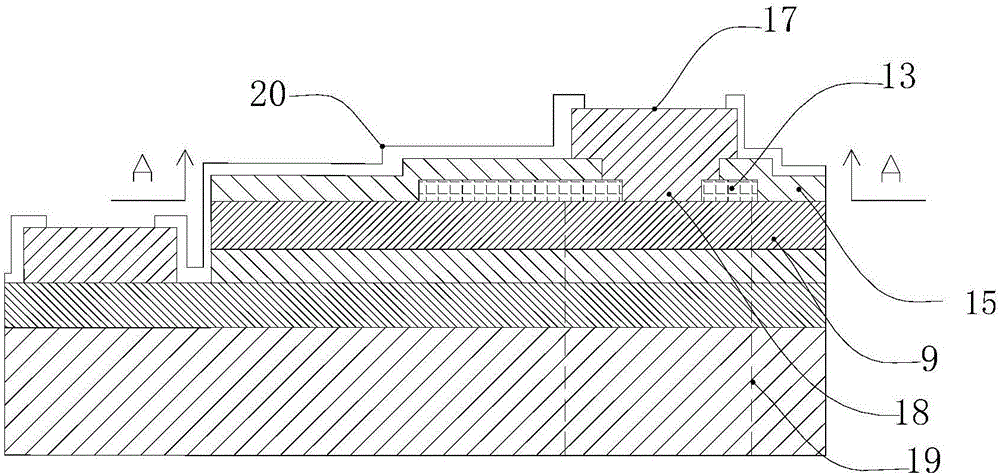

[0032] The present invention proposes a light-emitting semiconductor device with a complementary electrode layer, including a P electrode, a current diffusion layer is formed on the P electrode, a P electrode pad is formed on the current diffusion layer, and an insulating pad is formed under the P electrode pad. layer, the insulating layer is arranged around the electrode pad, and the projection of the P electrode pad is within the projection range of the insulating layer, and is arranged between the current diffusion layer and the P electrode; the P electrode pad is in contact with the P electrode A communication part, which passes through the current diffusion layer and the insulating layer and is in contact with the P electrode.

[0033] The present invention proposes a method for manufacturing a light-emitting semiconductor device with complementary electrode layers, which comprises the following steps: growing a gallium nitride-based semiconductor multilayer structure on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com