Field emission illumination light source

A lighting source and emitter technology, applied in the field of field emission lighting sources, can solve the problems of high driving voltage, low utilization rate of anode reflective layer, low luminous efficiency of diode structure and grid structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

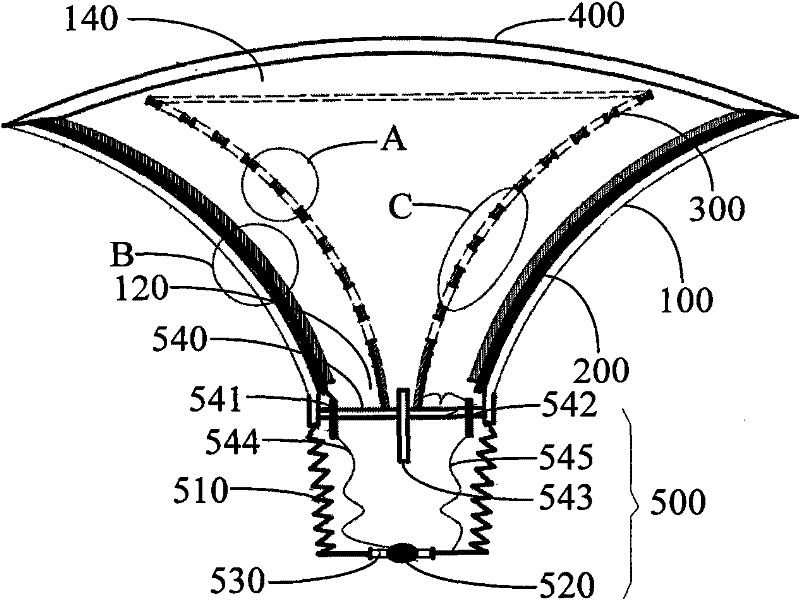

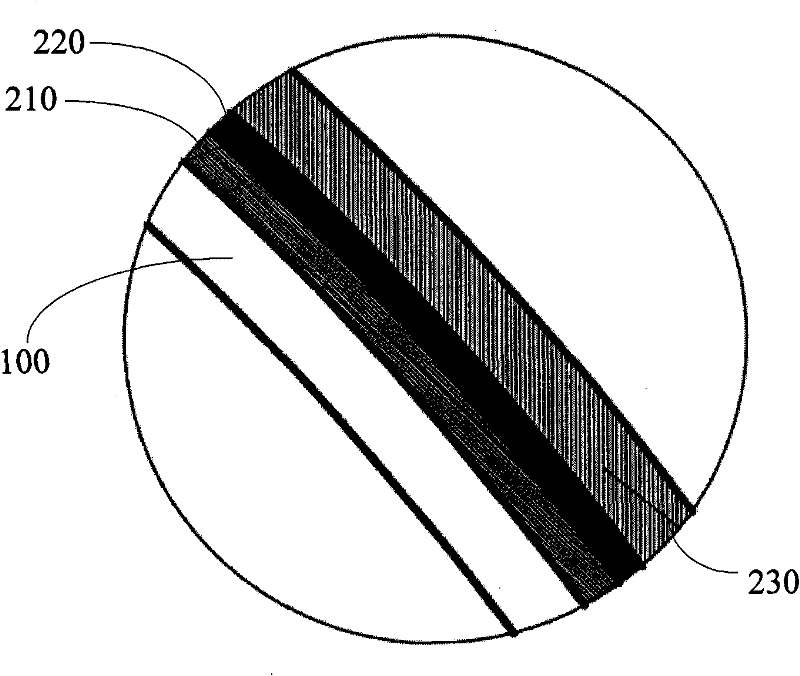

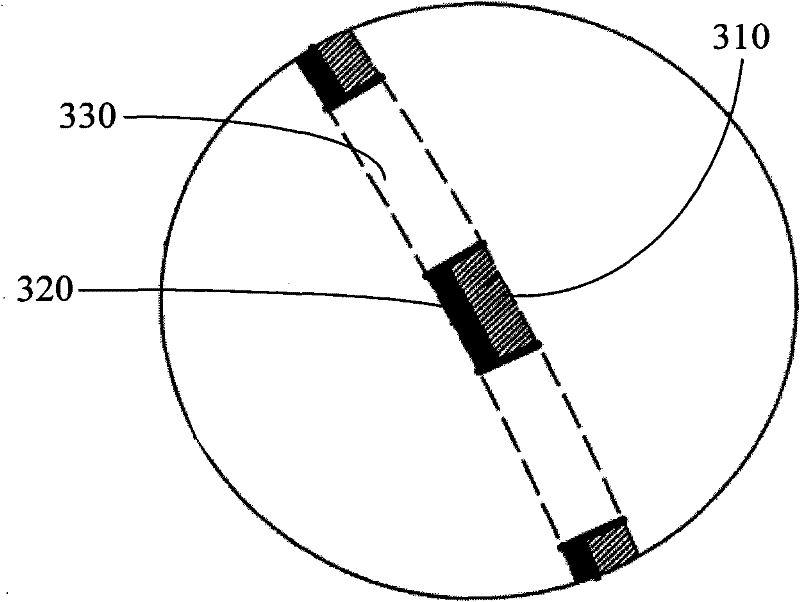

[0021] Such as figure 1 As shown, the field emission lighting source of an embodiment includes a hollow cylindrical housing 100 , an anode 200 , a cathode 300 , a transparent member 400 and a lamp cap 500 . One end of the casing 100 is connected to the lamp cap 500 , and the other end is closed by the transparent member 400 . The anode 200 is arranged in the side wall of the housing 100, the cathode 300 and the anode 200 are both adapted to the shape of the side wall of the housing 100, the cathode 300 is fixed on the lamp holder 500 and is opposite to the anode, and a plurality of light-transmitting holes are opened on the cathode .

[0022] The casing 100 is roughly funnel-shaped. Two ends of the housing 100 are respectively provided with an installation opening 120 and a light outlet 140 . The sidewall of the housing 100 is arc-shaped. The width of the housing 100 gradually increases along the axial direction away from the installation opening 120 , so that the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com