Cement asphalt mortar with high elastic damping

A technology of mortar and cement, which is applied in the field of cement asphalt mortar, can solve the problems of low early strength of cement emulsified asphalt mortar, poor stability of emulsified asphalt, and needs to be improved, so as to improve crack resistance, volume stability, stable performance, and good damping performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

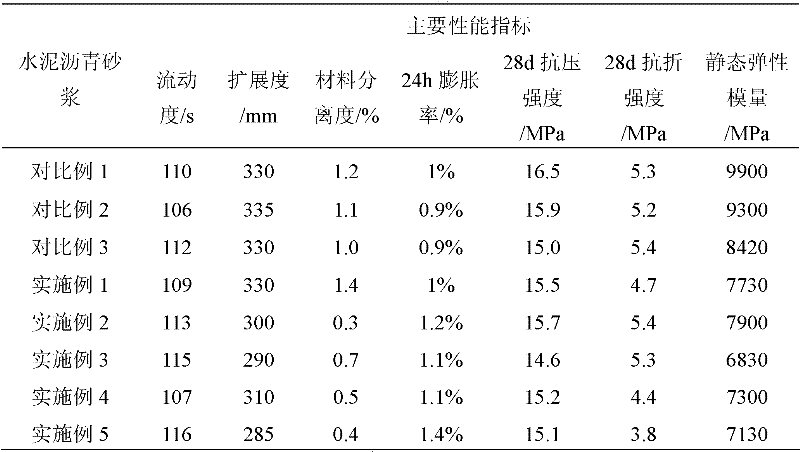

Examples

Embodiment 1

[0024] Embodiment 1, the preparation of cement asphalt mortar

[0025] (1) Preparation of dry powder: mix P I 42.5 cement, UEA expansion agent, river sand (fineness modulus 1.4), aluminum powder (200 mesh) and rubber powder (30 mesh particle size) and stir evenly to obtain dry powder ; Wherein, the ratio of mass and number of PI 42.5 cement, UEA expansion agent, river sand, aluminum powder and rubber powder is 90: 10: 132: 0.005: 3;

[0026] (2) Preparation of cement asphalt mortar: mix slow-cracking anionic emulsified asphalt, water, polycarboxylate water reducer and silicone defoamer and stir evenly to obtain a liquid mixture, and put the liquid mixture into the dry powder obtained in the previous step The cement asphalt mortar can be obtained after being stirred evenly in the material; wherein, the mass-number ratio of PI 42.5 cement, UEA expansion agent, river sand, emulsified asphalt, water, water reducer, defoamer, aluminum powder and rubber powder is 90: 10:132:37:19:1...

Embodiment 2

[0028] Embodiment 2, the preparation of cement asphalt mortar

[0029] (1) Preparation of dry powder: mix and stir PI 52.5 cement, UEA expansion agent, river sand (fineness modulus 1.4), aluminum powder (200 mesh), rubber powder (200 mesh particle size) and polypropylene fiber Obtain dry powder evenly; Wherein, the mass and number ratio of PI 52.5 cement, UEA expansion agent, river sand, aluminum powder, rubber powder and polypropylene fiber is 90: 10: 132: 0.005: 3: 1.5;

[0030] (2) Preparation of cement asphalt mortar: mix slow-cracking anionic emulsified asphalt, water, polycarboxylate water reducer and silicone defoamer and stir evenly to obtain a liquid mixture, and put the liquid mixture into the dry powder obtained in the previous step The cement asphalt mortar can be obtained by mixing it evenly in the material; among them, the mass parts of P I 52.5 cement, UEA expansion agent, river sand, emulsified asphalt, water, water reducer, defoamer, aluminum powder, rubber po...

Embodiment 3

[0032] Embodiment 3, the preparation of cement asphalt mortar

[0033] (1) Preparation of dry powder: PII42.5 cement, UEA expansion agent, river sand (fineness modulus is 1.4), aluminum powder (200 mesh), rubber powder (particle size is 150 mesh) and polypropylene fiber are mixed and Stir evenly to obtain dry powder; wherein, the mass-number ratio of PII 42.5 cement, UEA expansion agent, river sand, aluminum powder, rubber powder and polypropylene fiber is 90:10:180:0.01:1:1;

[0034] (2) Preparation of cement asphalt mortar: mix slow-cracking anionic emulsified asphalt, water, polycarboxylate water reducer and silicone defoamer and stir evenly to obtain a liquid mixture, and put the liquid mixture into the dry powder obtained in the previous step The cement asphalt mortar can be obtained by mixing it evenly in the material; among them, the mass parts of PII 42.5 cement, UEA expansion agent, river sand, emulsified asphalt, water, water reducer, defoamer, aluminum powder, rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com