Process for synthesizing benzoquinones by direct oxidation of phenols

A technology of phenols and processes, applied in the preparation of oxidized quinones, organic chemistry, etc., can solve problems such as tar formation and target product yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

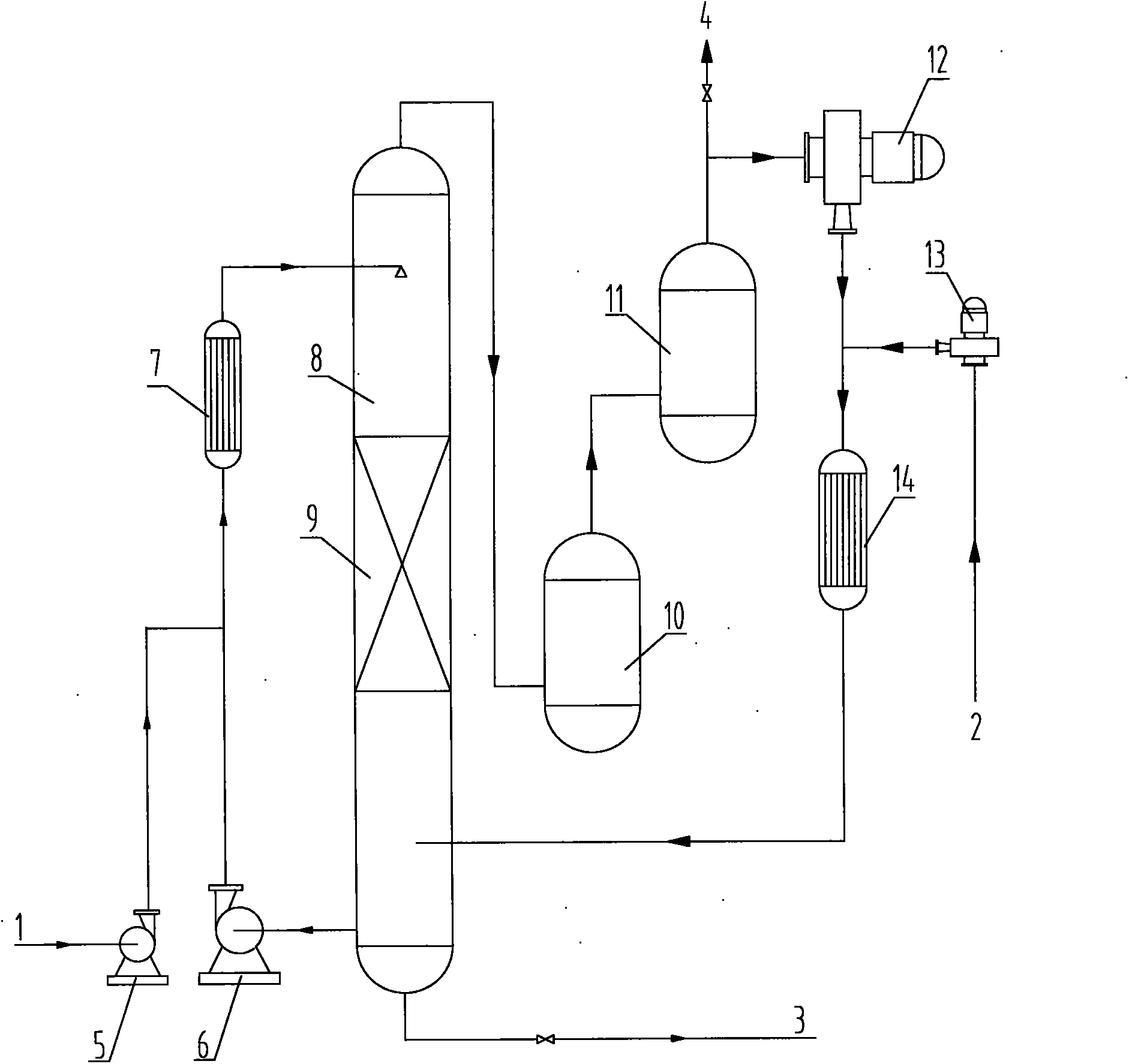

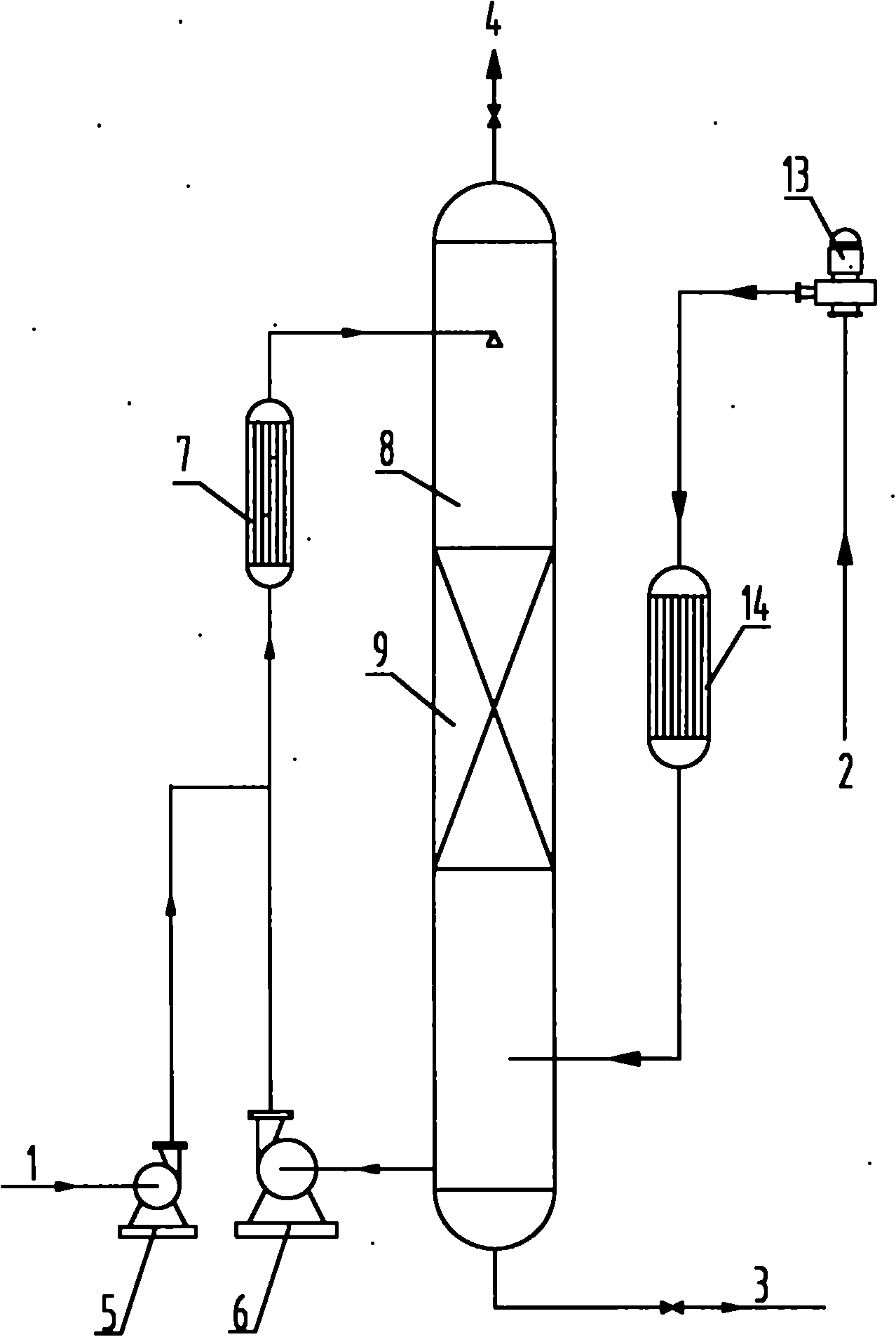

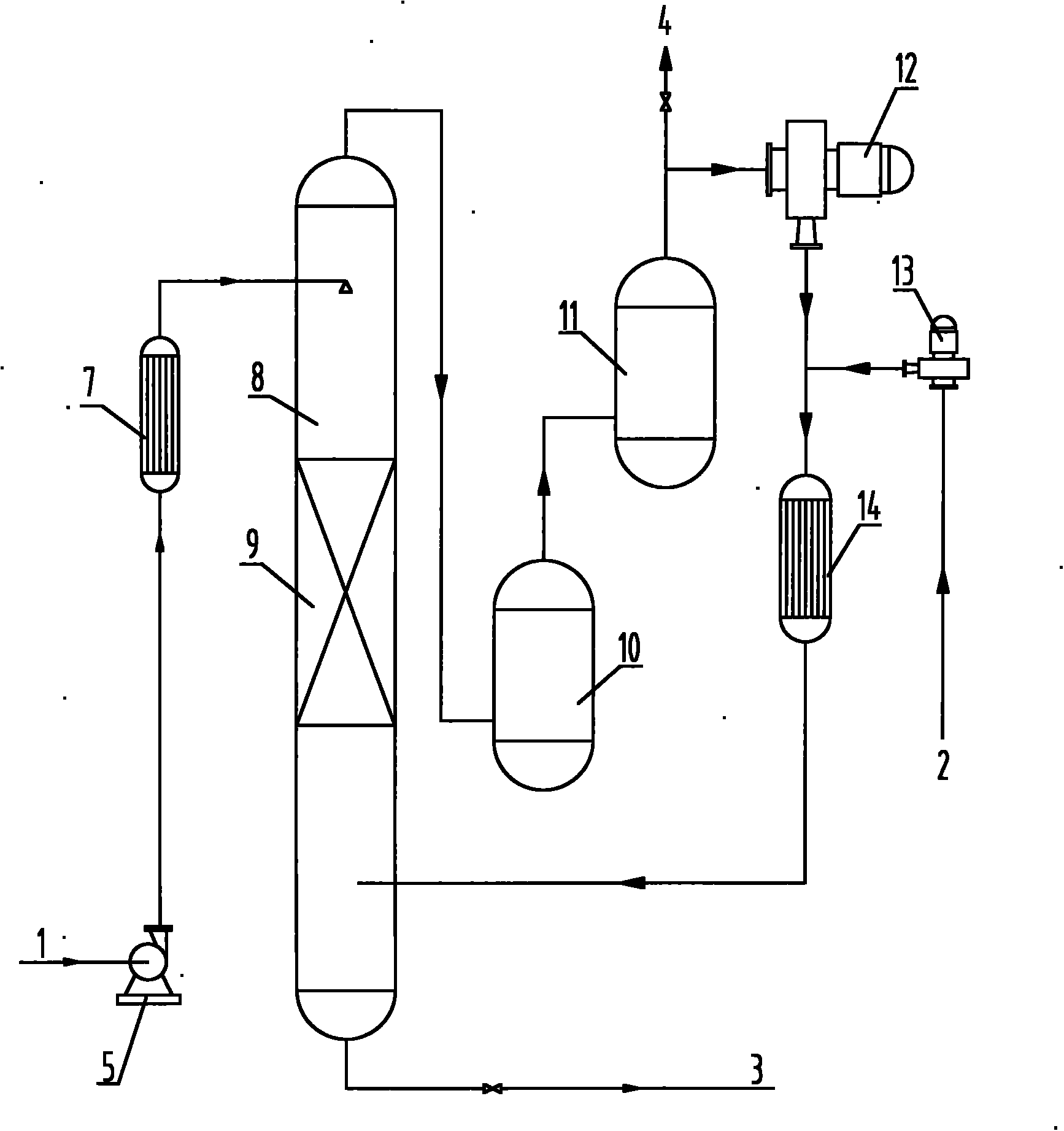

Method used

Image

Examples

Embodiment 1

[0101] In distilled water, add 5% phenol (weight ratio based on liquid phase feed), and 2.5% CuCl 2 / NaCl (molar ratio)=1: 3 mixture (weight ratio based on liquid-phase feed) as catalyzer, control reaction temperature is 70-80 ℃, and reaction pressure is 3.0-3.2MPa, respectively in reactor (below Referred to as No. 1 reactor for short), traditional reaction tower (filler and large grain copper are housed in the reaction tower, particle diameter 3-10mm) (hereinafter referred to as No. 2 reactor), reaction tower of the present invention (with copper wire as filler , the diameter of the copper wire≤2mm) (hereinafter referred to as No. 3 reactor), the reaction tower (atomized feed) of the present invention (hereinafter referred to as No. 4 reactor), the reaction tower of the present invention (with copper wire as filler , simultaneously in the reactor of atomized feed form) (hereinafter referred to as No. 5 reactor), carry out oxidation reaction with oxygen as oxygenant, and react...

Embodiment 2

[0104] The distilled water among the embodiment 1 is replaced with methyl alcohol, other conditions are constant, and reaction result is as shown in the table below:

[0105]

Embodiment 3

[0107] The distilled water among the embodiment 1 is replaced with ethanol, other conditions are constant, and reaction result is as shown in the table below:

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com