Production method of esterquats

A technology of ester-based quaternary ammonium salts and production methods, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxyl compounds, etc., and can solve problems such as high product odor, low output, and small production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

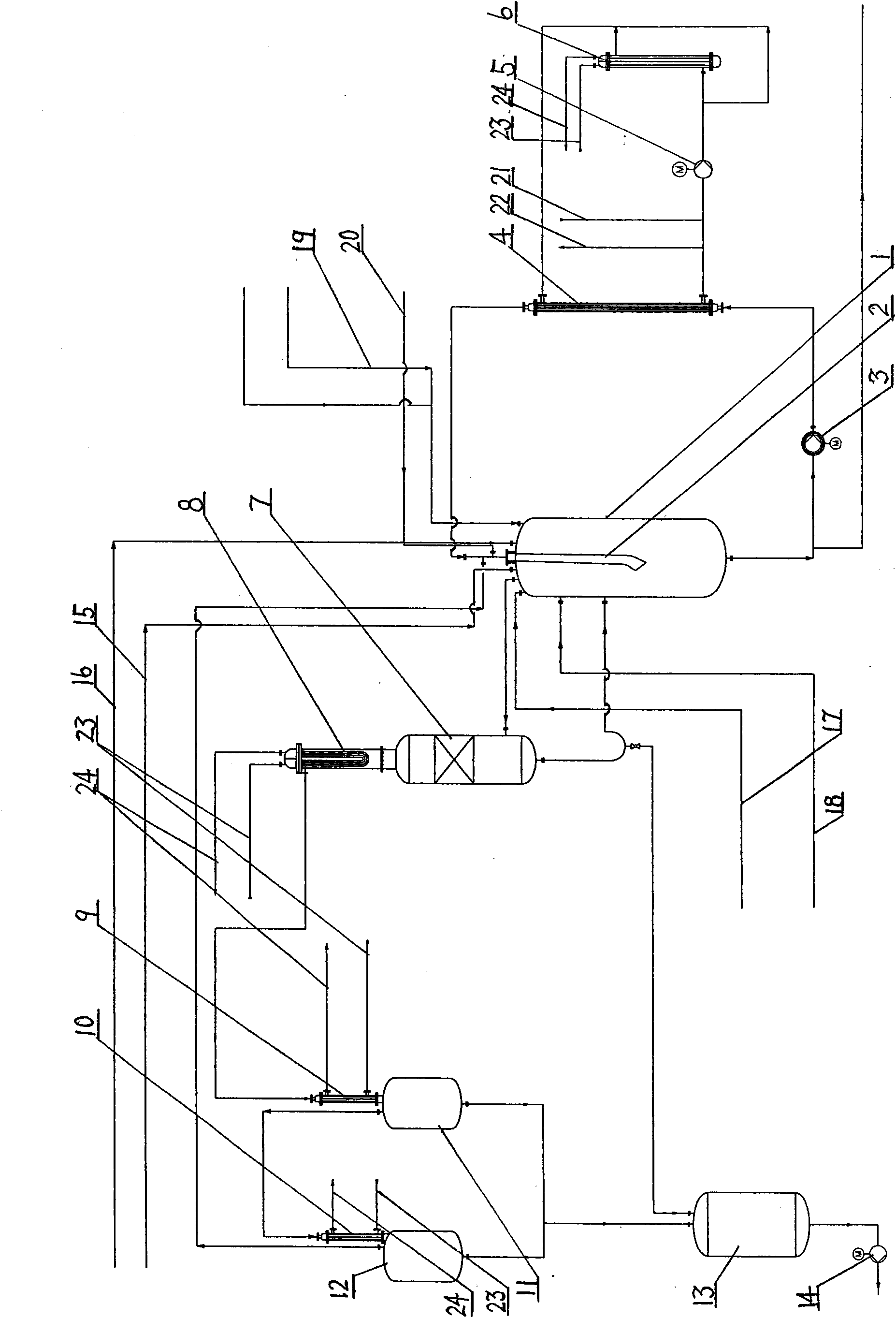

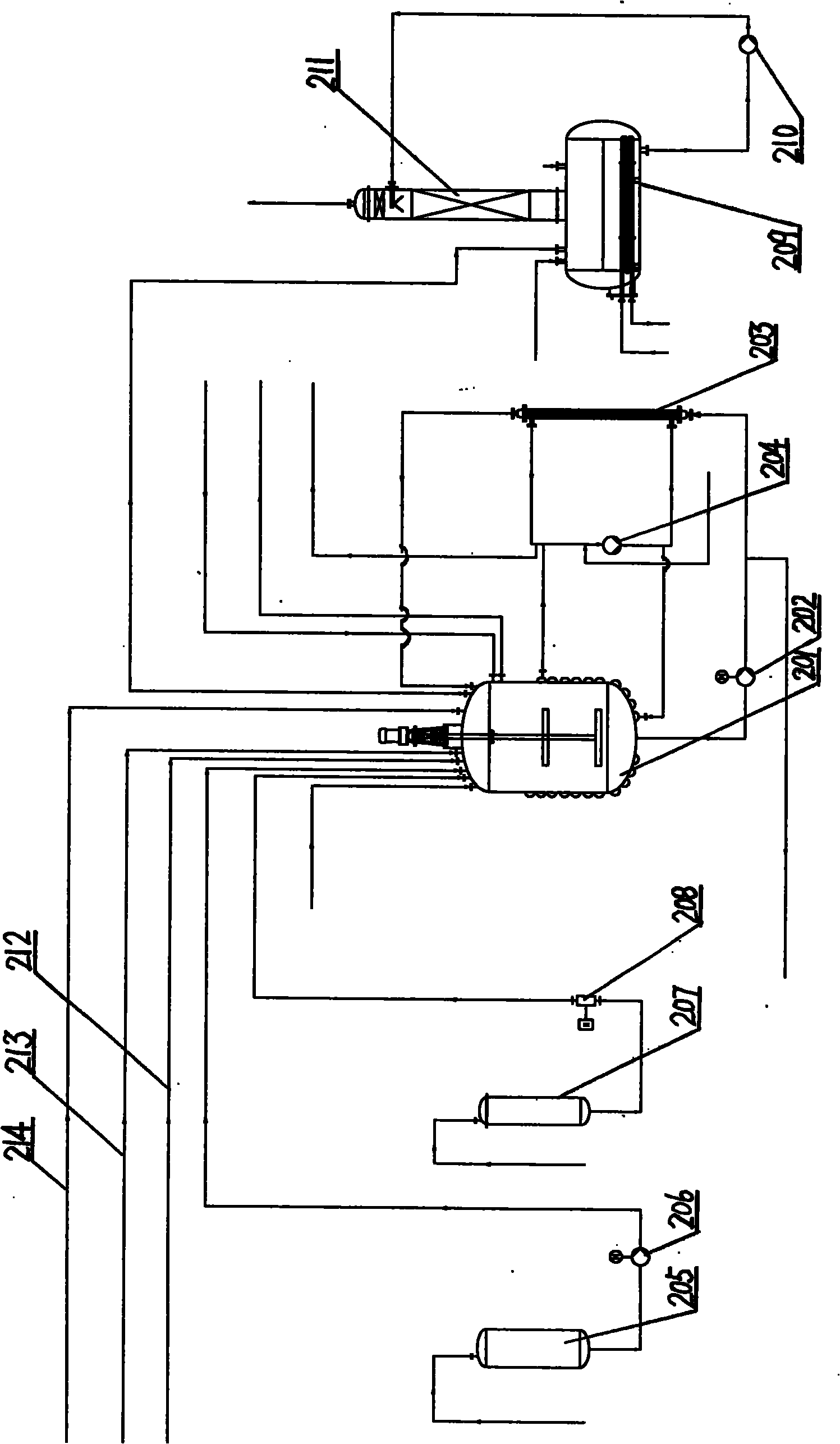

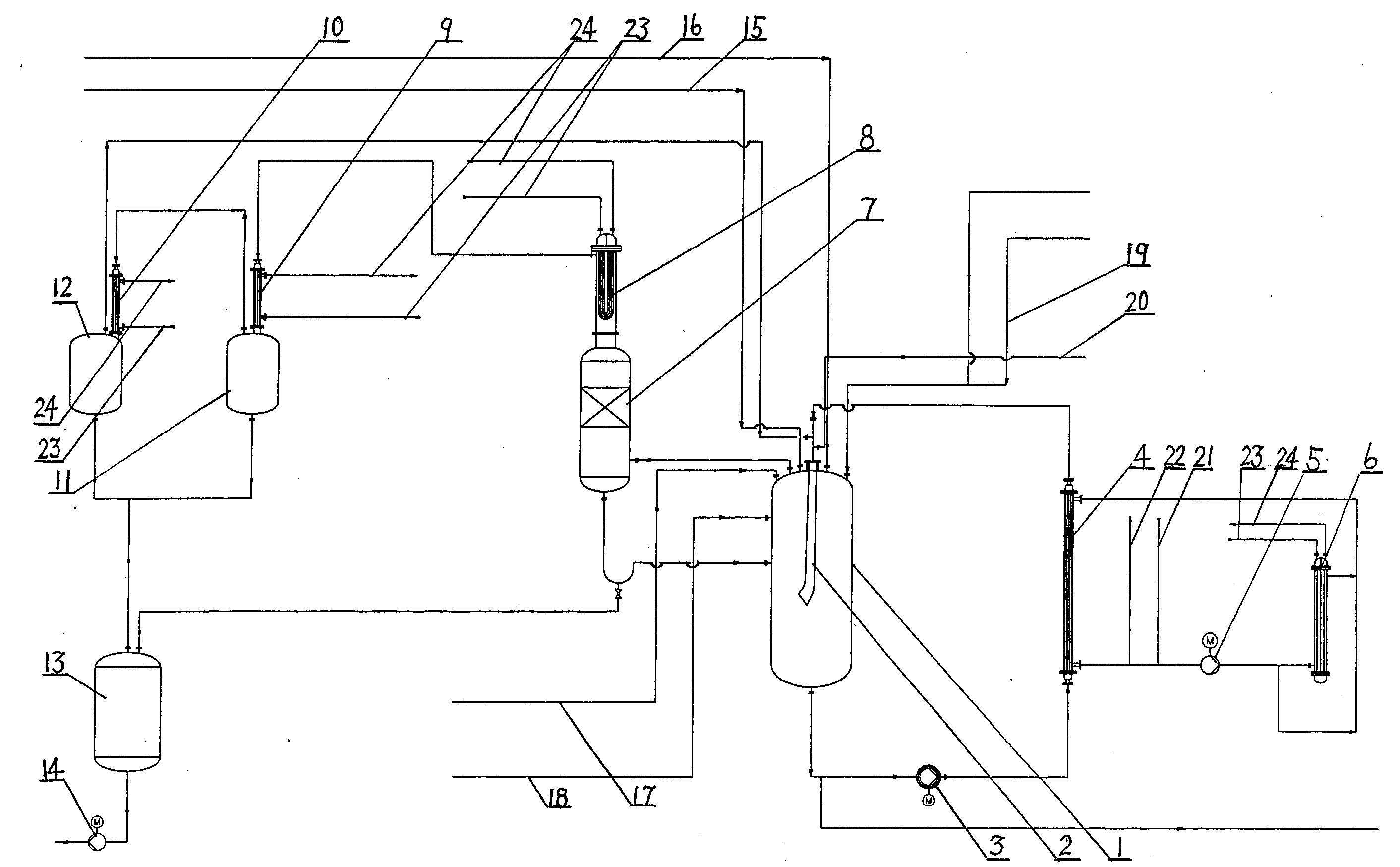

Method used

Image

Examples

Embodiment 1

[0032] A kind of production method of ester group quaternary ammonium salt, described method has production ester amine step and utilizes ester amine to produce quaternary ammonium salt step successively,

[0033] In the step of producing esteramine, add fatty acid, catalyst and conditioner to the loop reactor fully replaced with nitrogen, then raise the temperature and continuously add alkanolamine, and control the pressure in the loop reactor to be 0.05Mpa , the reaction temperature is 220°C, and the reaction time is 2.0 hours. When the acid value of the reactant is 6 mgKOH / g, the reaction is terminated, and the ester amine is obtained after passing through steam for deodorization treatment;

[0034]In the step of using esteramine to produce quaternary ammonium salt, the esteramine is cooled to 68°C, pumped into the quaternization reactor with agitator, and the alkylating agent is continuously added to the quaternization reactor. Stir and react with the esteramine under exte...

Embodiment 2

[0038] A kind of production method of ester group quaternary ammonium salt, described method has production ester amine step and utilizes ester amine to produce quaternary ammonium salt step successively,

[0039] In the step of producing esteramine, add fatty acid, catalyst and conditioner to the loop reactor fully replaced with nitrogen, then raise the temperature and continuously add alkanolamine, and control the pressure in the loop reactor to be 0.50Mpa , the reaction temperature is 180°C, the reaction time is 3.5 hours, the reaction is terminated when the acid value of the reactant is 0.5 mgKOH / g, and the ester amine is obtained after passing through steam for deodorization treatment;

[0040] In the step of using esteramine to produce quaternary ammonium salt, the esteramine is cooled to 71°C, pumped into the quaternization reactor with agitator, and the alkylating agent is continuously added to the quaternization reactor. Stir and react with the esteramine under extern...

Embodiment 3

[0044] A kind of production method of ester group quaternary ammonium salt, described method has production ester amine step and utilizes ester amine to produce quaternary ammonium salt step successively,

[0045] In the step of producing esteramine, add fatty acid, catalyst and conditioner to the loop reactor fully replaced with nitrogen, then raise the temperature and continuously add alkanolamine, and control the pressure in the loop reactor to be 0.25Mpa , the reaction temperature is 200°C, and the reaction time is 2.8 hours. When the acid value of the reactant is 3.2KOH / g, the reaction is terminated, and the ester amine is obtained after passing through steam for deodorization treatment;

[0046] In the step of producing quaternary ammonium salt by using ester amine, the temperature of ester amine is lowered to 70°C, pumped into the quaternization reactor with agitator, and the alkylating agent is continuously added to the quaternization reactor. Stir and react with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com