Test structure for analyzing through-hole type metal-interconnected electromigration reliability

A test structure, metal interconnection technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of destroying the integrity of the test structure, unfavorable comprehensive analysis of chips, etc., to achieve convenient and quick positioning, improve efficiency, and save use time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

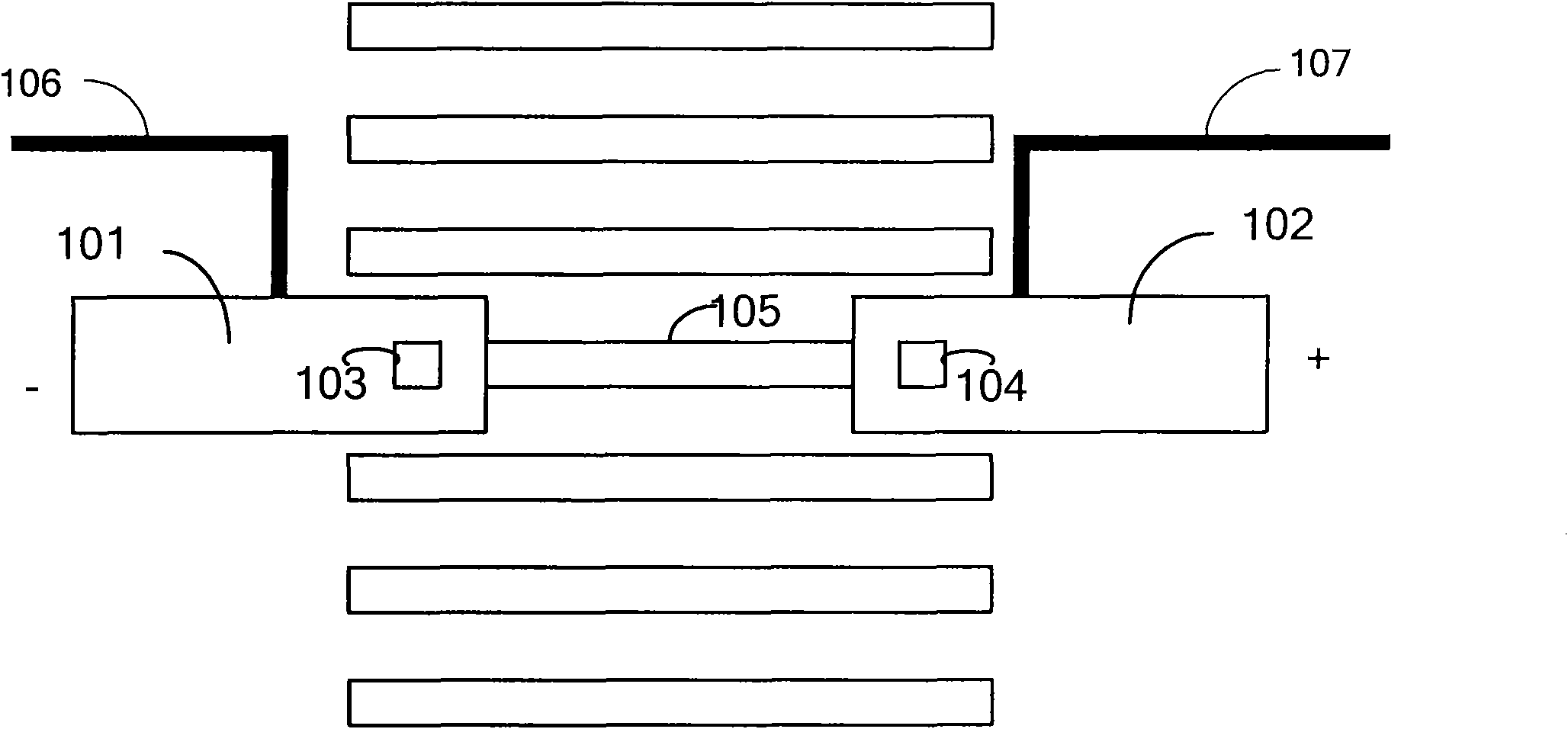

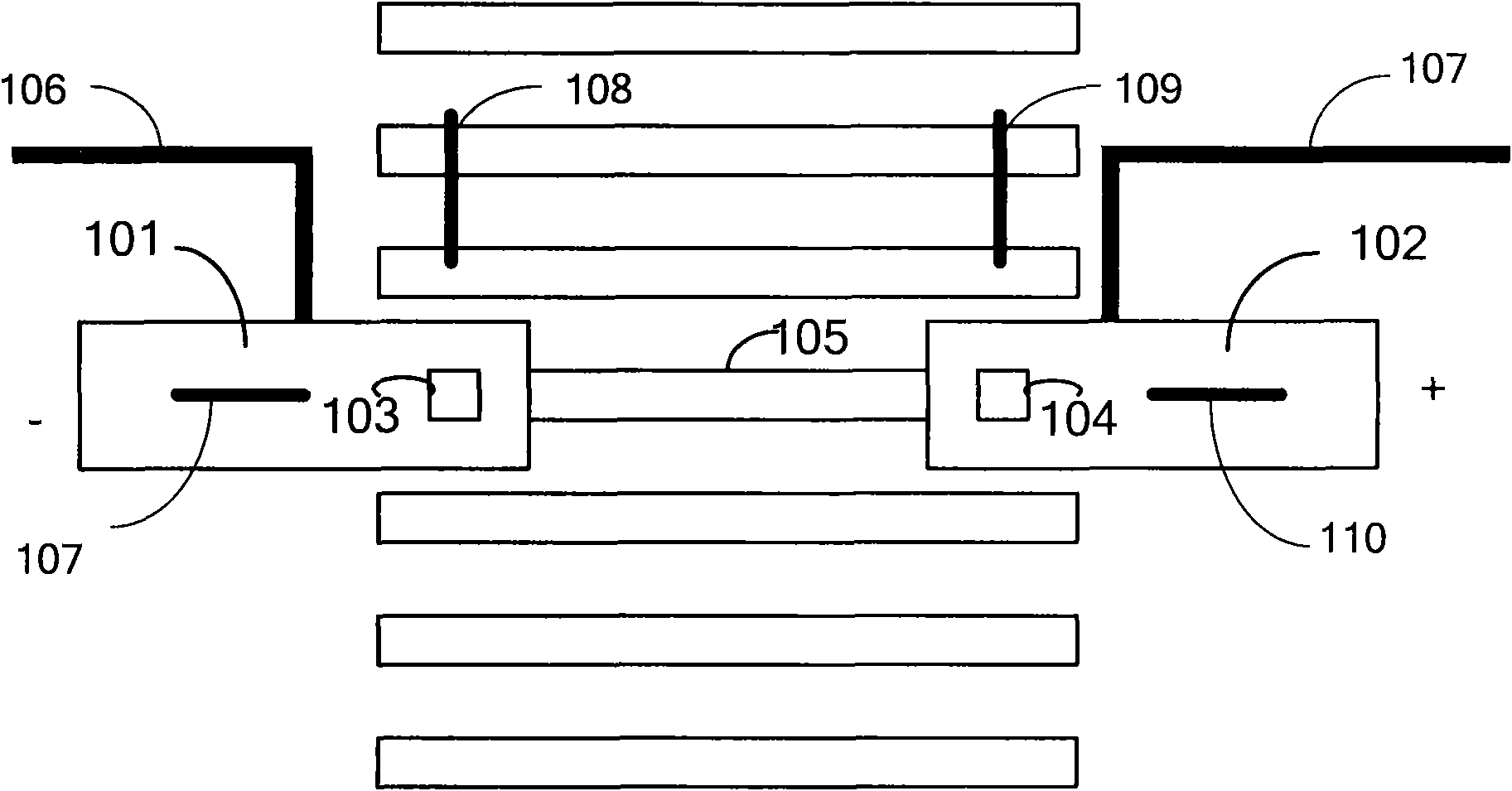

[0022] The top view of the test structure for analyzing the electromigration reliability of through-hole metal interconnection proposed by the embodiment of the present invention is as follows image 3 shown. The test structure includes at least two layers of metal wires, an insulating medium layer is filled between adjacent metal wires in each layer, the metal wires of adjacent layers are separated by an insulating medium layer, and the metal wires of adjacent layers Conduction is realized by metal vias, and at least one insulating dielectric layer is covered on the top layer metal line. and figure 2 Compared with the top view of the existing test structure shown, the difference is that the insulating dielectric layer covering the top metal line of the test structure contains a metal mark for indicating the position of the metal via.

[0023] The shape of each metal marker is preferably a rectangle (or other shapes similar to a rectangle, such as a rounded rectangle, or a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com