Operating fuel tank

A technology of working fluid and container, which is applied in the field of working fluid container, and can solve problems such as pressure compensation element function hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

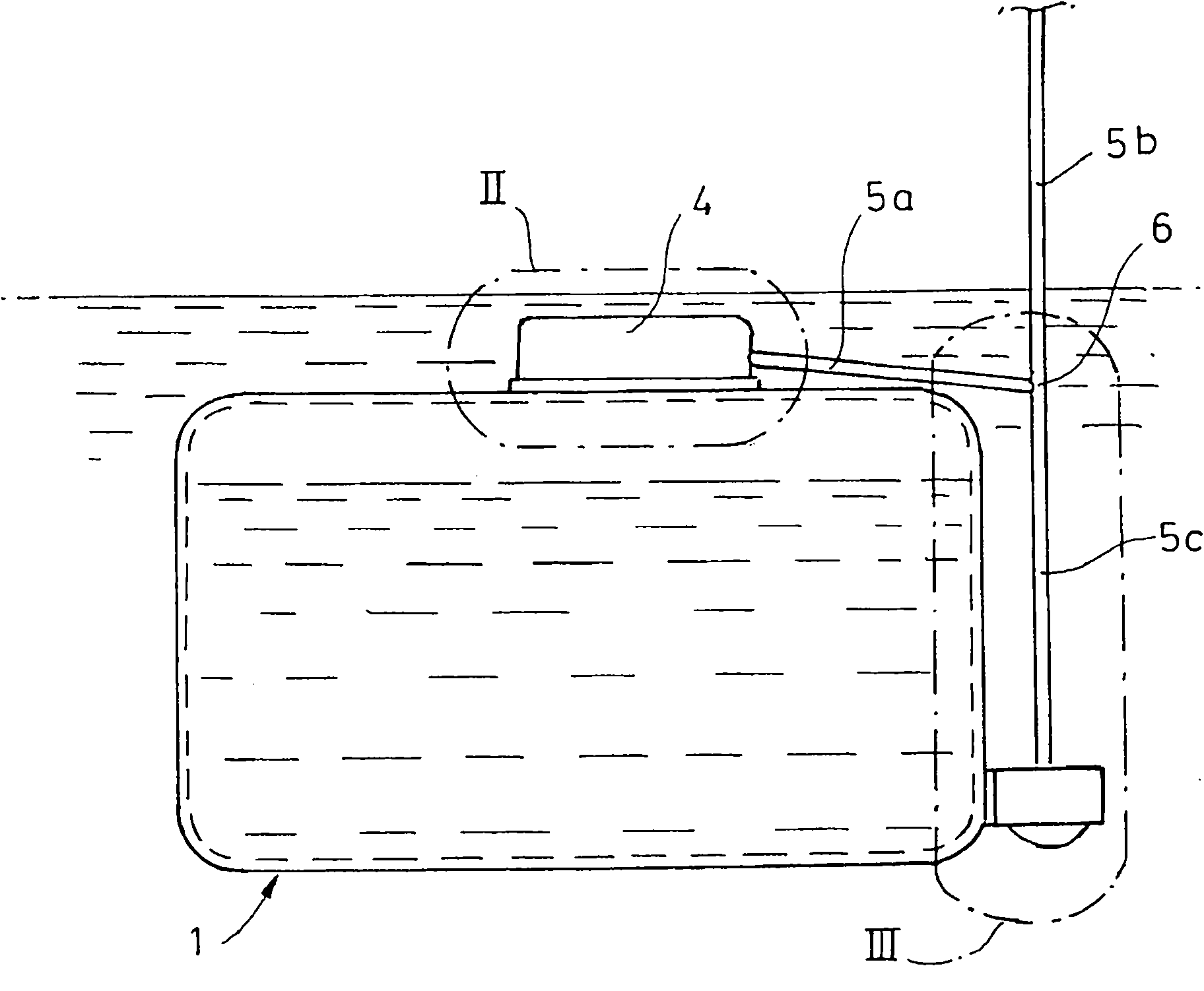

[0018] Reducing agent container 1, if it is in figure 1 As shown in, it can be composed of any material and made in any manner and method. However, the reducing agent container 1 is preferably composed of a thermoplastic and obtained by extrusion blow molding. The reducing agent container can be arranged concealed in the rear area of the motor vehicle body or in the engine compartment of the motor vehicle, for example. The reducing agent container 1 serves to contain urea present in an aqueous solution, which urea is sprayed into the exhaust line of a motor vehicle upstream of a so-called SCR catalyst. Ammonia and carbon dioxide are produced from the urea aqueous solution through a hydrolysis reaction. Ammonia can reduce nitrogen oxides in exhaust gas at a corresponding temperature in the SCR catalyst.

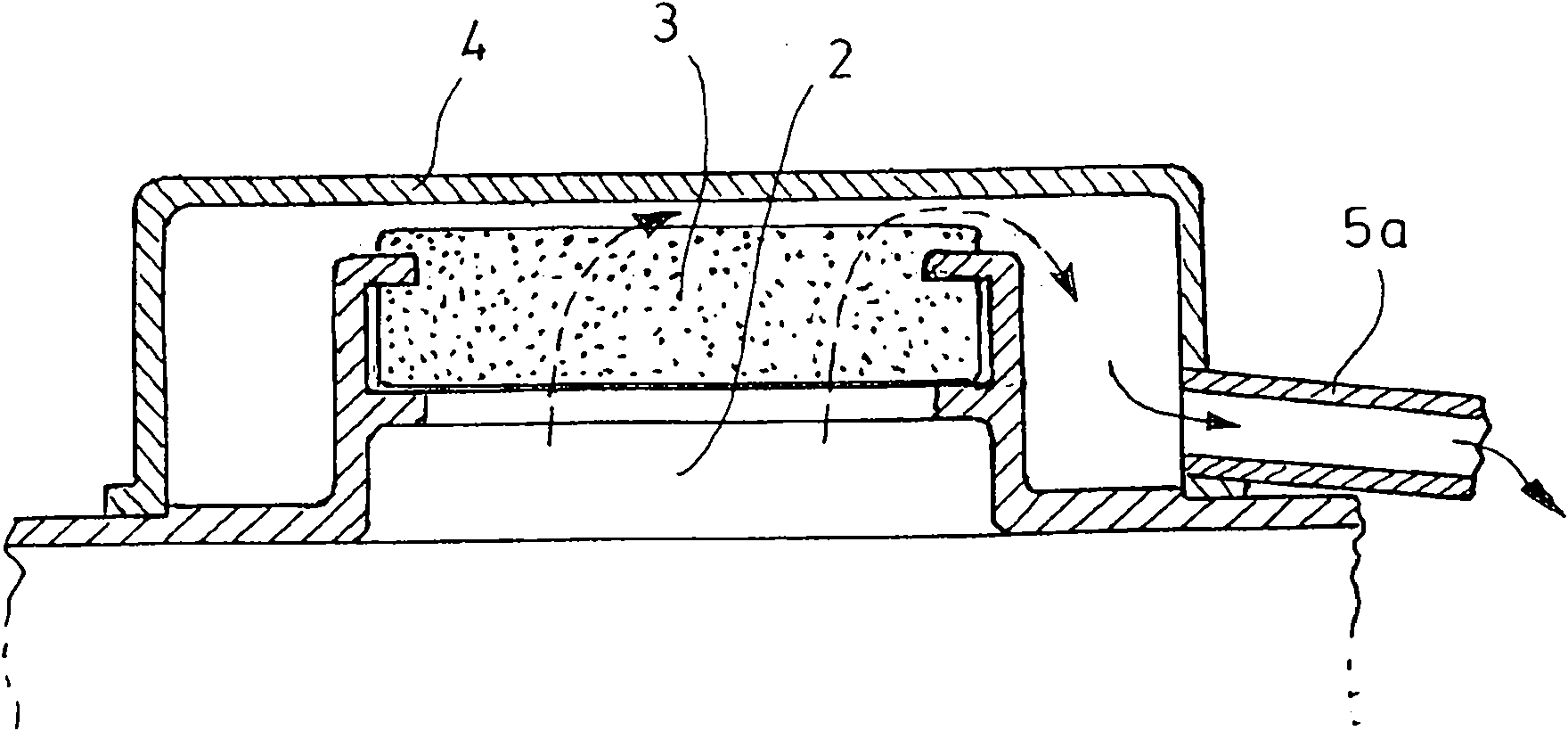

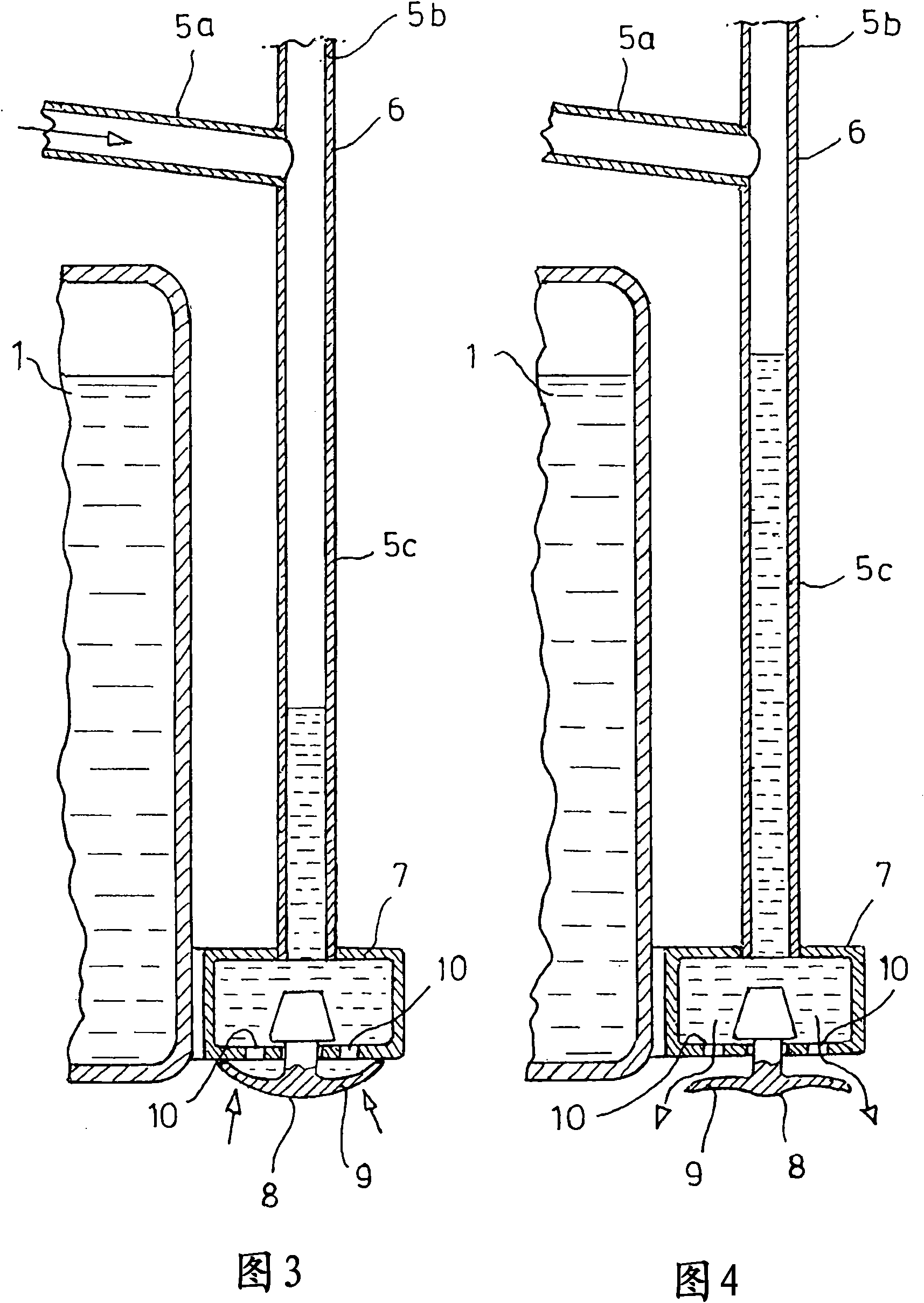

[0019] As this can be particularly drawn from the drawings, a central air inlet and outlet opening 2 is provided on the upper side of the reducing agent container 1 in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com