box device

A technology of installation position and vehicle box, which is applied in the box device field of SCR box, can solve problems such as leakage at the floating valve, achieve reliable ventilation, and prevent crystal formation and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

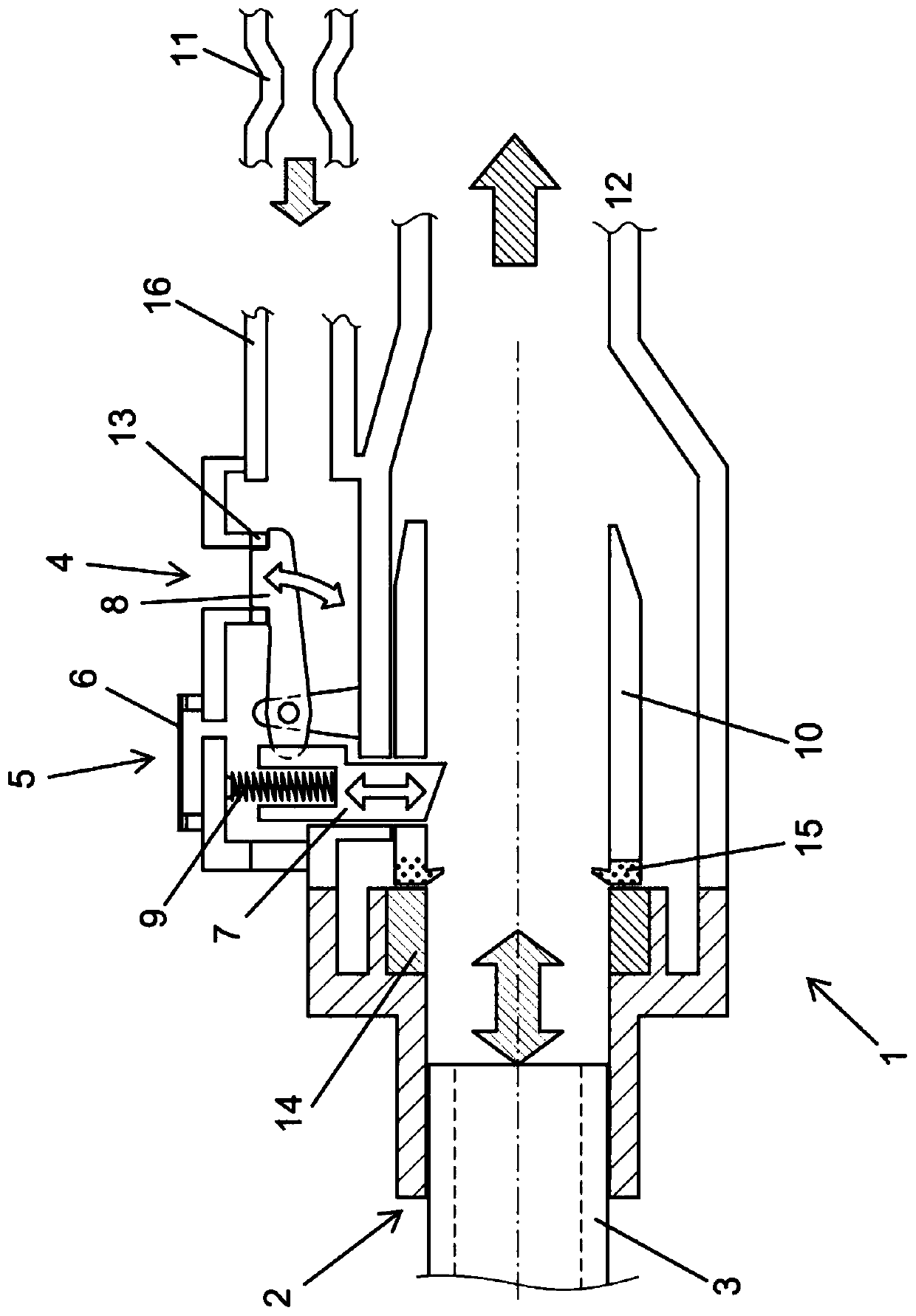

[0024] The box device according to the invention is in figure 1 shown in , which is provided as a motor vehicle tank for filling an SCR tank, in particular a urea tank.

[0025] The tank arrangement comprises, in addition to the motor vehicle tank (not shown), a filling head 1 for filling the motor vehicle tank, which forms a connection to the filling pipe 12 in the region of the indicated arrow at the right end of the filling head 1 . Transition Department.

[0026] In the fill tube head 1's figure 1 The left end of the is provided with a filling opening 2 for introducing a nozzle 3 to fill the motor vehicle tank through the nozzle 3.

[0027] The filling opening 2 of the filling nozzle 1 forms a transition to the flow guiding device 10 via an annular magnet 14 and a likewise radial lip seal 15 .

[0028] During the introduction of the nozzle 3, the filling ventilation opening 4 is open, the filling ventilation opening 4 is formed radially on the outside of the flow guidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com