Method and device for the angle sensor-free position detection of the rotor shaft of a permanently excited synchronous machine based on current signals and voltage signals

A synchronous motor and rotor shaft technology, applied in motor generator control, control of electromechanical transmissions, electric/electrical converters, etc., can solve problems such as inaccurate rotor angles, insufficient machine models, etc., and achieve real-time calculation and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

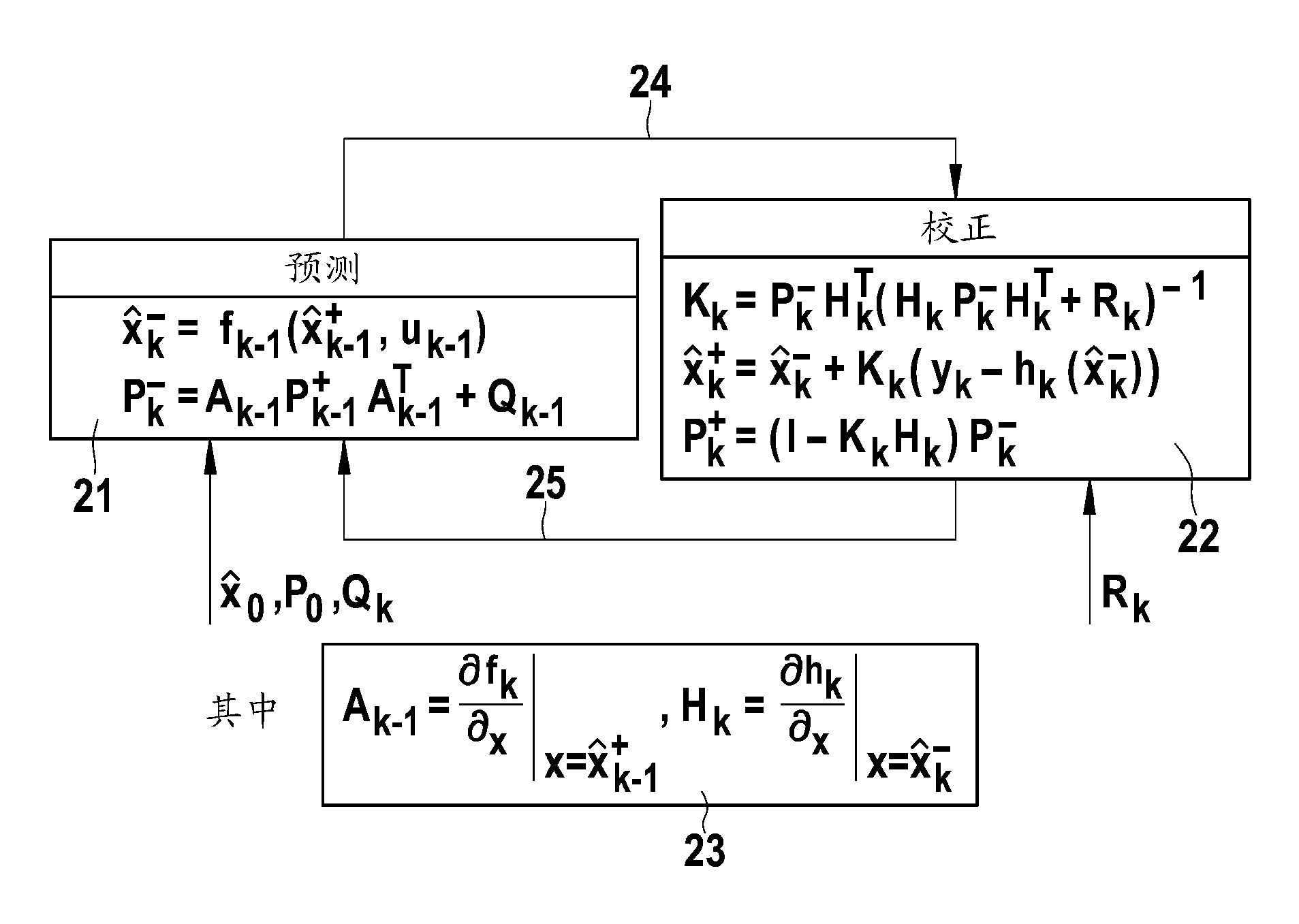

[0070] exist figure 1 The schematic structure of the dq fundamental model with input / output transformation is shown in . Motor input or machine voltage U in the αβ coordinate system fixed relative to the stator or relative to the location αβ 14 through the rotation matrix T ( ) 11 is transformed into the input signal U in the dq coordinate system fixed relative to the rotor dq .

[0071] The transformed input signal U dq is input to the machine model ∑ dq 12 in. Machine model∑ dq 12 as output with the estimated rotation angle (position) 16 and machine current I dq . Machine current I fixed relative to the rotor dq By inverse rotation matrix T -1 ( ) 13 is converted back to the fixed machine current I relative to the stator αβ 15, which is converted back to the output quantity. rotation angle 16 is fed here to the rotation matrix T ( )11 and the inverse rotation matrix T -1 ( ) 13, where applicable:

[0072] and .

[0073] figure 2 The predictor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com