Automatic box-type or utensil-type kitchen-catering liquid material controller capable of being automatically sealed

A liquid material automatic control and automatic sealing technology, which is applied in kitchen utensils, household utensils, applications, etc., can solve the problem that soft plastic bottle caps cannot be adapted to various bottle bodies, unsatisfactory, hygienic liquid outlets and air intake pipes Inconvenient to use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

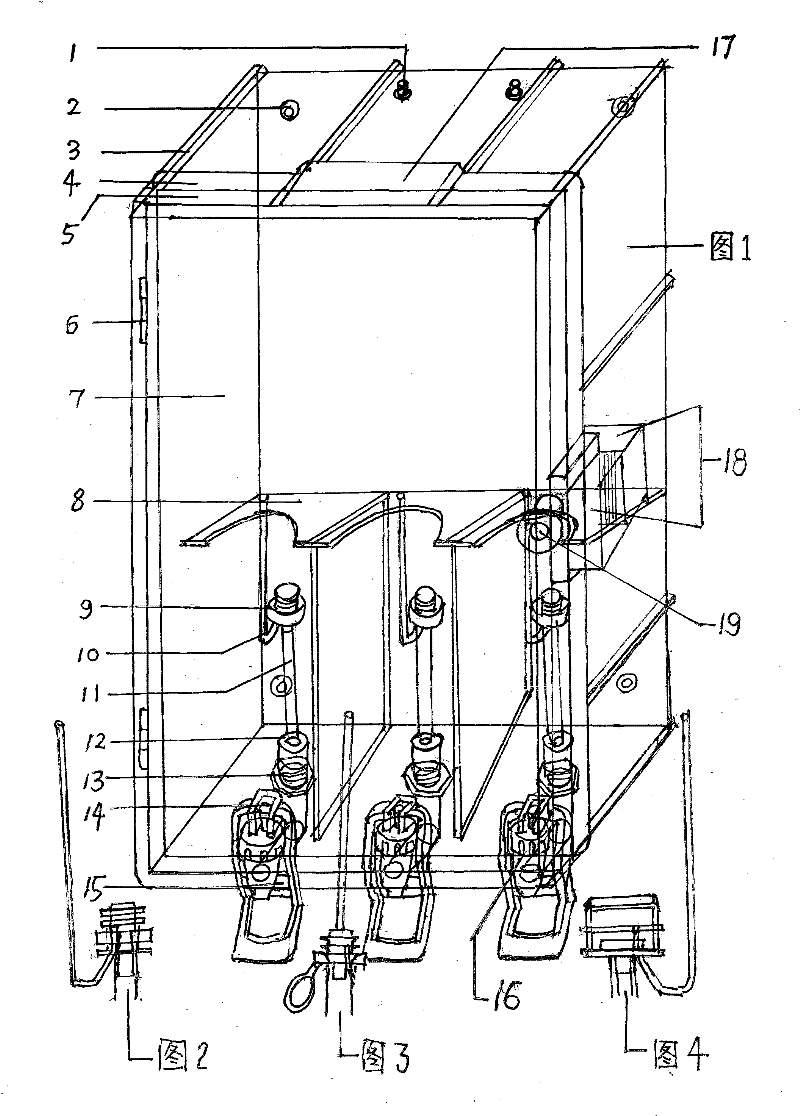

[0023] exist figure 1 Among them, the box-type liquid material self-control consists of vent plug hole 1, box wall nail hole 2, box reinforcement rib 4, box mouth thick frame 5, box cover thick frame 6, and transparent box cover surface 7. There are three gears Mouth cushion layer 8, soft rubber bottle cap 9, air intake elbow 10, silicone infusion tube 11, threaded elbow upward part 12, handle cap with silk opening 13, upper end of hydraulic control guide plate with sealing plate The pin 14 that plays a connecting role between the hole position and the central rod hole position, the sealing plate 15, the automatic valve bonnet and the valve body and the central rod and the spring 16 in the silicone plug and the plunger, and the upper edge of the box body. Handle position 17, the upper and lower assembly 18 that magnetic force sucks touch, case cover handle 19 is formed.

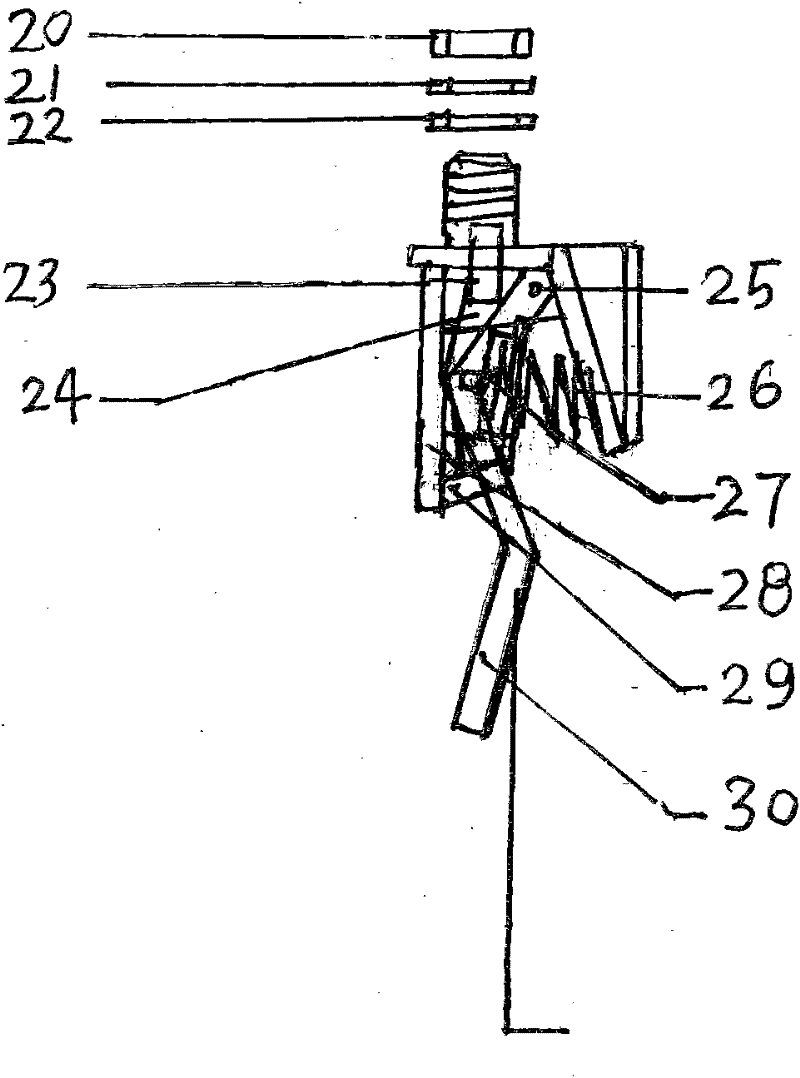

[0024] exist Figure 7 Among them, the pan-type liquid material automatic controller consists of a threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com