High-efficiency combined water purifier

A water purifier and high-efficiency technology, applied in the field of water treatment, can solve the problems of high energy consumption of pump stations, heavy maintenance workload, and large head loss of pipelines, etc., to achieve expanded filtration area, small footprint, and short water production time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

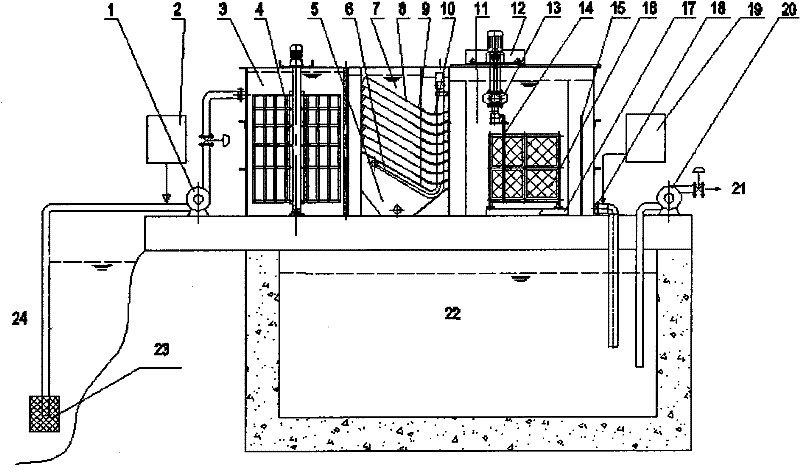

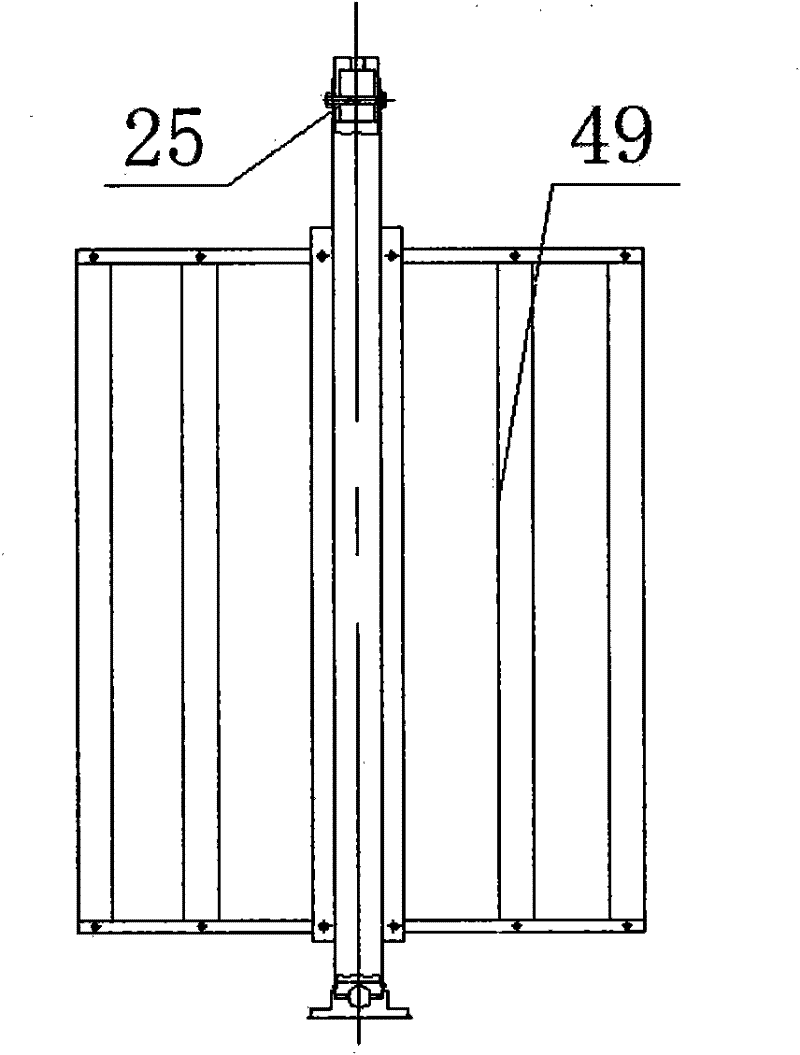

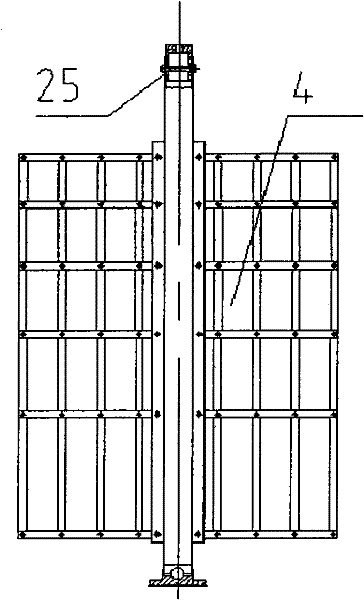

[0045] like figure 1 As shown, the device consists of water inlet pump 1, coagulant dosing device 2, reaction tank 3, grid variable hole stirring paddle 4, sludge bucket 5, forced outlet pipe 6, sedimentation tank 7, co-current swash plate 8. Sedimentation water collector 9, clean water outlet hose 10, filter tank 11, dredging truck 12, dredging pump 13, dredging pipe 14, water outlet weir 15, blanket filter 16, water collecting trunk 17, Clean water outlet 18, disinfectant dosing device 19, clean water lifting pump 20, user water 21, clean water pool 22, water intake 23 and river course 24 are formed. The reaction tank 3 mainly carries out the coagulation process. The raw water is drawn by the water inlet pump 1, and the raw water and the chemical agent are fully mixed and stirred, and then enters the sedimentation tank 7, and the sedimentation tank 7 carries out preliminary precipitation, and most of the settled sludge is discharged from the bottom of the sedimentation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com