A kind of high-performance α-pinene isomerization catalyst and its application

A catalyst and isomerization technology, applied in the direction of physical/chemical process catalysts, isomerization hydrocarbon production, molecular sieve catalysts, etc., can solve the problem of low total selectivity and achieve the effect of excellent performance, good selectivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

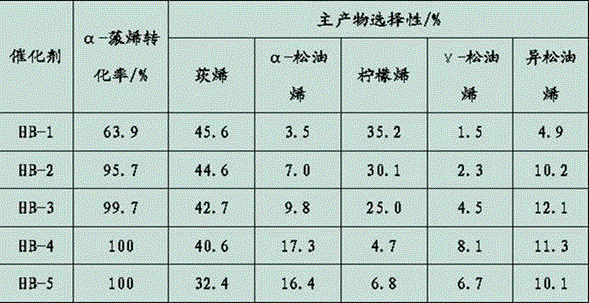

Embodiment 1

[0016] 3 g of commercial Beta molecular sieves were poured into a certain amount of NH 4 Cl solution at 70 o Exchange at C for 2h, suction filter, wash, 110 o C drying, 550 o C was calcined for 5 hours, and the catalyst was designated as HB-1.

[0017] Pour 3g of commercial Beta molecular sieve into a certain amount of NaOH solution (0.1, 0.2mol / L) at 65 o C stirring for 30min, suction filtration, washing, 110 o C drying, 550 o C was calcined for 5 hours, and the obtained catalysts were designated as HB-2 and HB-3, respectively.

[0018] 3g of HB-1 before roasting was poured into a certain amount of citric acid (0.5mol / L) at 85 o C stirring for 4h, suction filtration, washing, 110 o C drying, 550 o C roasting for 5h, then add a certain amount of NaOH solution (0.2mol / L) to the obtained material at 65 o C for 30min, suction filtration, washing, 110 o C drying, 550 o C was calcined for 5 hours, and the obtained material was designated as HB-4.

[0019] 3g of HB-1 bef...

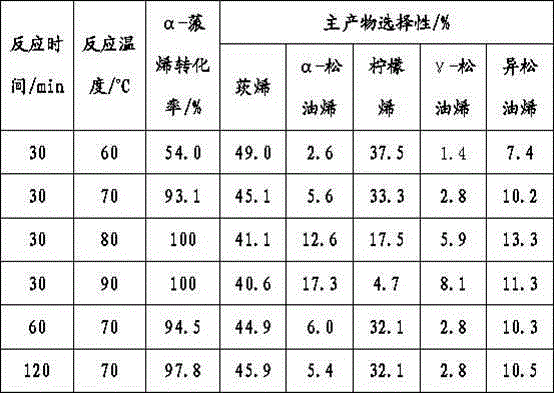

Embodiment 2

[0024] By the HB-4 catalyst prepared in embodiment 1, at 60-90 oC The isomerization reaction of α-pinene was carried out for 30min respectively, and at 70 o C for 60 min and 120 min of isomerization. Other conditions are with embodiment 1. The results are shown in Table 2: HB-4 catalyzed α-pinene isomerization reaction results.

[0025] Table 2

[0026]

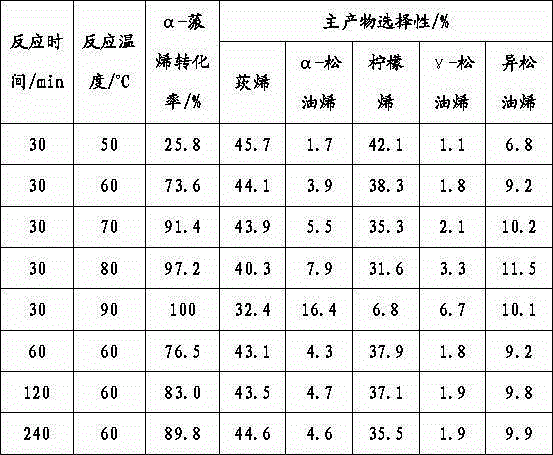

Embodiment 3

[0028] By the HB-5 catalyst prepared in embodiment 1, at 50-90 oC Under the reaction temperature of α-pinene, carry out the isomerization reaction of 30min respectively, and at 60 o C for 60 min, 120 min and 240 min of isomerization. Other conditions are with embodiment 1. The results are shown in Table 3: HB-5 catalyzed α-pinene isomerization reaction results.

[0029] table 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com