Method for capturing specific laser processing beam spot through projection imaging

A laser processing and projection technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as control uncertainty, and achieve the effect of suppressing uncertainty and sharpening the edge of the beam spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

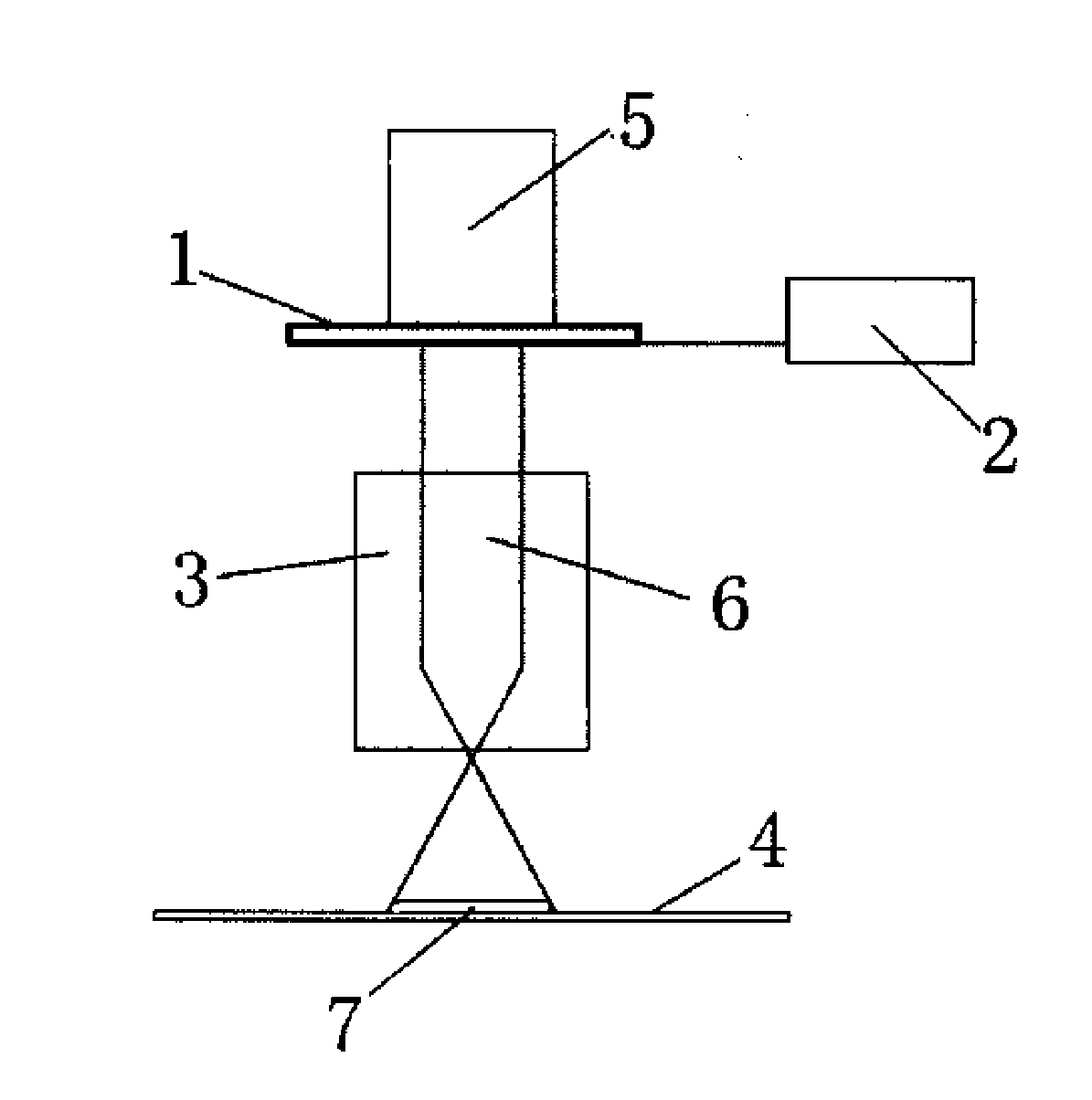

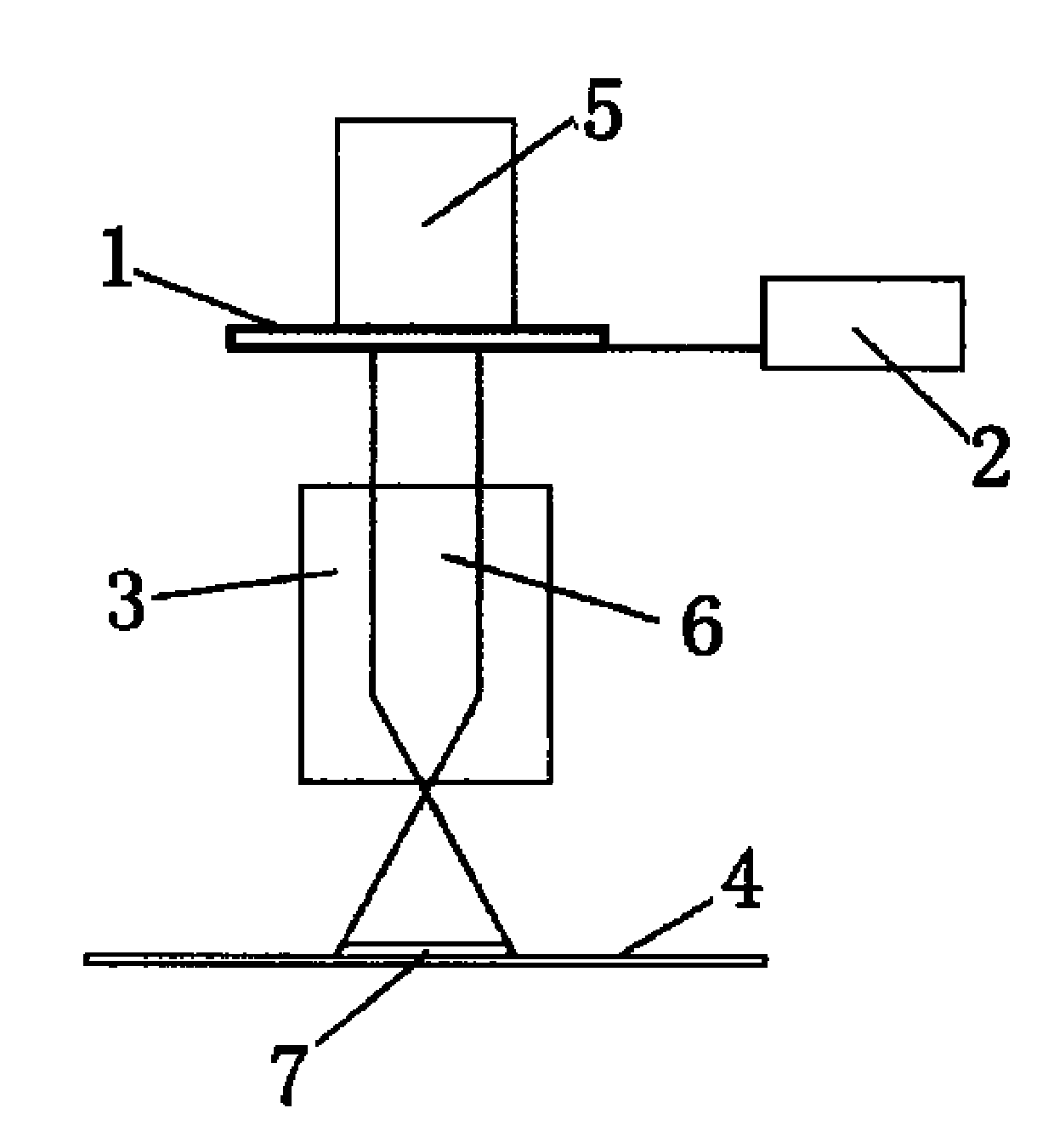

[0015] The object of the present invention is to provide a method for obtaining a specific laser processing beam spot by means of projection imaging. The present invention adopts a projection imaging system to realize the beam shaping process, in addition to obtaining the desired shape of the beam spot, it can also suppress the diffraction part at the edge of the beam spot and obtain the sharp edge of the beam spot. The composition of the projection imaging system is as follows:

[0016] The projection imaging system generally consists of three parts, one is the object, the other is the imaging lens group, and the third is the screen and image. The composition of the projection imaging system is as follows: figure 1 shown.

[0017] Among the figure, design a series of light-transmitting figures on the photolithography plate 1 (mainly adopt the figures with middle width, upwards or downwards gradually reducing to zero in geometric shape, such as trapezoid or regular polygon; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com