MOF-74 hybrid shell structure material and ZIF-90@MOF-74 hybrid core-shell material

A ZIF-90, MOF-74 technology, applied in the field of metal organic frameworks, can solve the problems of long synthesis reaction process and time-consuming, inflexible control of the size and structure of core-shell crystal materials, and increased complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The first aspect of the present invention provides a method for preparing a MOF-74 hybrid shell structure material, comprising:

[0073] 1) Provide ZIF-90, dissolve ZIF-90 in alcohol to form ZIF-90 alcohol suspension;

[0074] 2) providing a precursor solution, which includes an organic ligand, an organic solvent, a nickel salt, water, a growth regulator, and an alkali;

[0075] 3) Mix the ZIF-90 alcohol suspension provided in step 1) with the precursor solution provided in step 2); prepare the MOF-74 hybrid shell structure material after reacting at 80-120°C for 3-9 minutes .

[0076] In the preparation method of the MOF-74 hybrid shell structure material provided by the present invention, in the step 1), ZIF-90 is provided, and ZIF-90 is dissolved in alcohol to form a ZIF-90 alcohol suspension. In one embodiment, the preparation method of ZIF-90 comprises: heating imidazole-2-carboxaldehyde and polyvinylpyrrolidone in a metal bath in a solvent, and then adding zinc ...

Embodiment 1

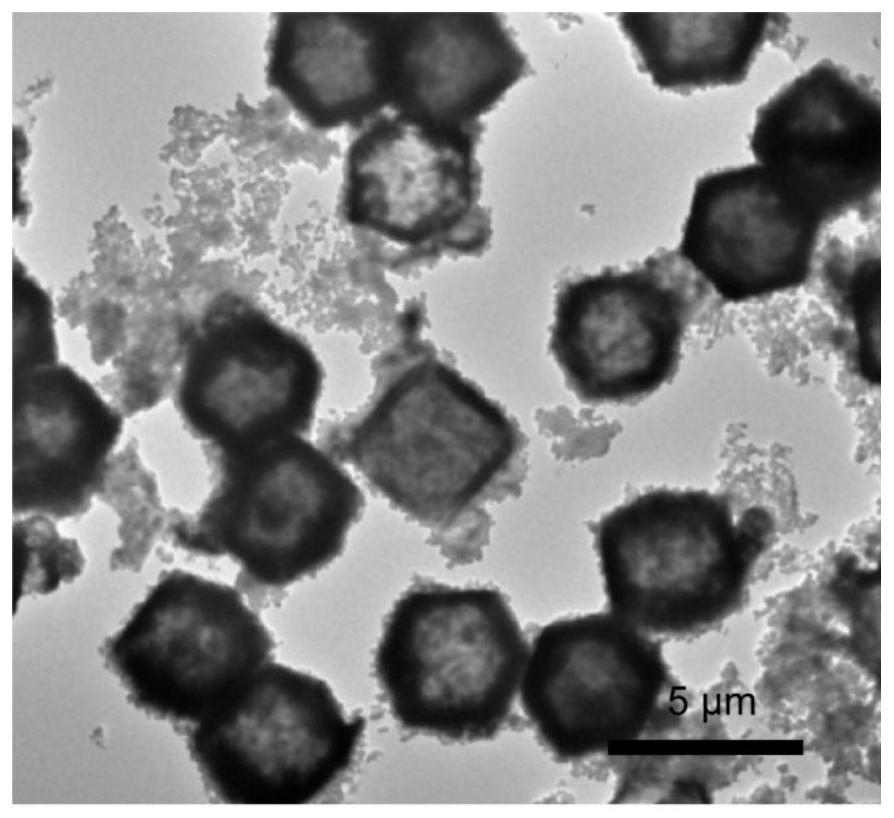

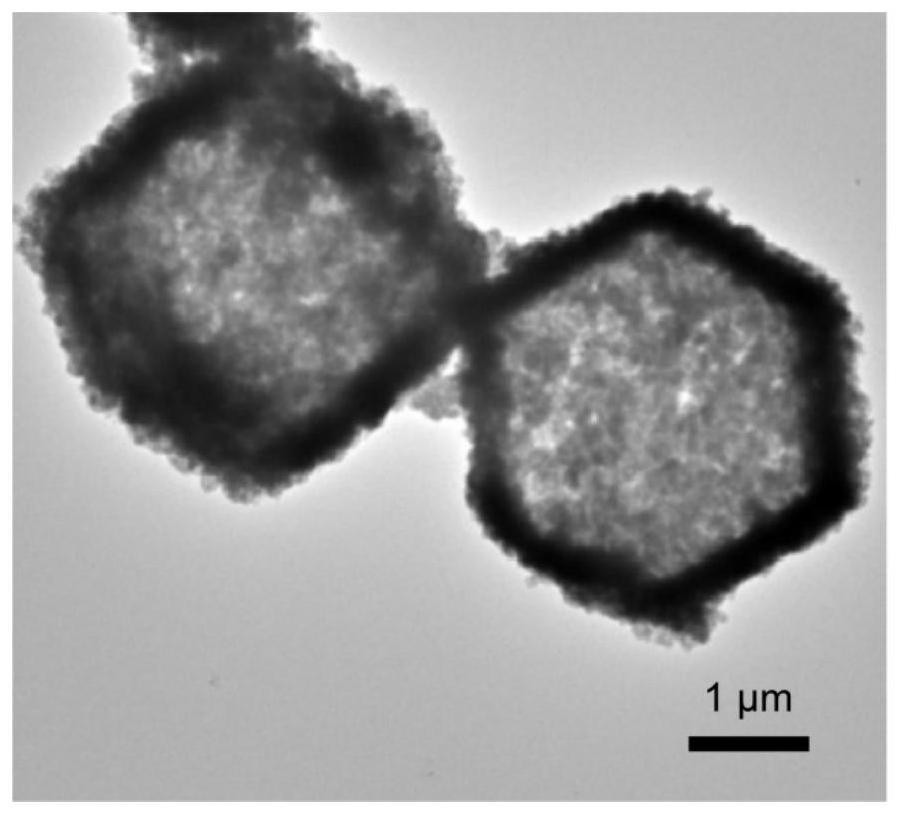

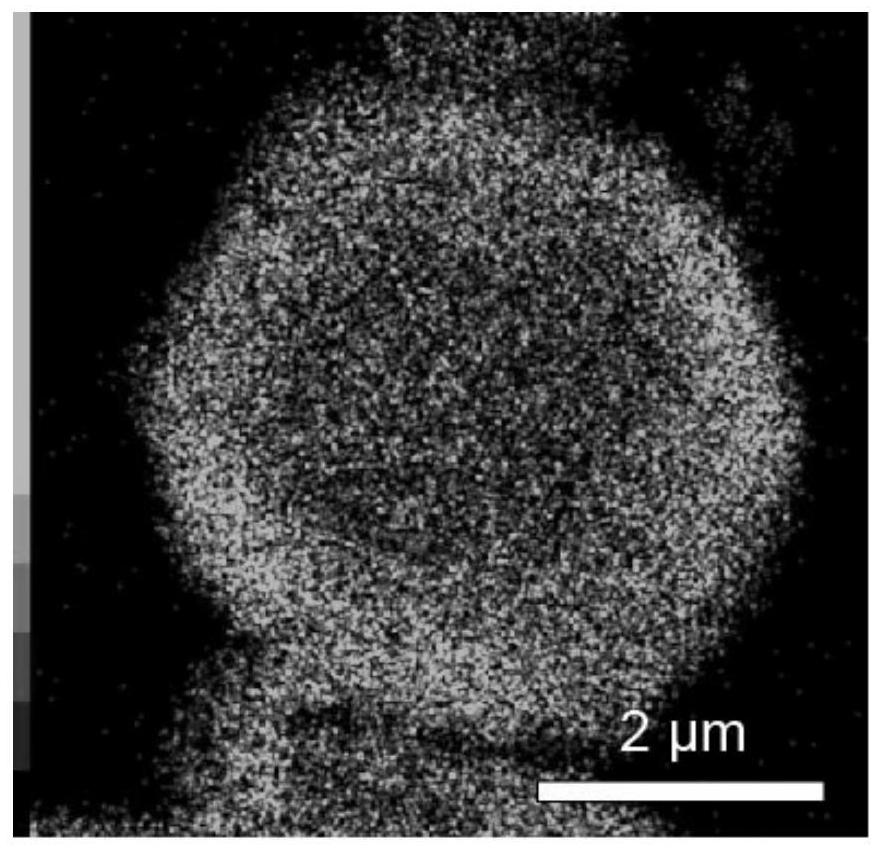

[0137] 1) Synthesis of 3-4 μm ZIF-90

[0138] Dissolve 360 mg of imidazole-2-carbaldehyde and 37.5 mg of PVP in 12.5 mL of deionized water, stir and heat in a metal bath at 80 °C to dissolve completely, and cool to 40 °C after complete dissolution. Add 1.25 mL of 0.62 mol / L zinc nitrate solution, and stir on a magnetic stirrer for 10 minutes (500 rpm). The product was washed twice with ethanol, collected by centrifugation (5000rpm / min, 5min), and ultrasonically dispersed in 0.6mL of ethanol.

[0139] 2) Synthesis of 3-4 μm MOF-74 hybrid shell material

[0140] Add 0.688 mL of 0.073 mol / L 2,5-dihydroxyterephthalic acid in N,N-dimethylformamide solution, 0.45 mL of 1 mol / L aqueous solution of nickel nitrate hexahydrate, 14.25 μL of acetic acid and 0.375mL of 1mol / L sodium hydroxide standard solution, ultrasonically homogenize the flocculent precipitate produced in the above solution or until the solution is clear, add 0.6mL of the ZIF-90 ethanol suspension synthesized above,...

Embodiment 2

[0144] 1) Synthesis of 8-9μm ZIF-90

[0145] Dissolve 720mg of imidazole-2-carbaldehyde and 75mg of PVP in 25mL of deionized water, stir and heat in a metal bath at 80°C to completely dissolve, add 1mL of PBS buffer solution after complete dissolution, and cool to 40°C. Add 2.5 mL of 0.62 mol / L zinc nitrate solution, and stir on a magnetic stirrer for 10 minutes (500 rpm). The product was washed twice with ethanol, collected by centrifugation (5000rpm / min, 5min), and ultrasonically dispersed in 0.6mL of ethanol.

[0146] 2) Synthesis of 8-9 μm MOF-74 hybrid shell material

[0147] Add 0.688 mL of 0.073 mol / L 2,5-dihydroxyterephthalic acid in N,N-dimethylformamide solution, 0.45 mL of 1 mol / L nickel nitrate hexahydrate aqueous solution, 14.25 μL of acetic acid and 0.375mL of 1mol / L sodium hydroxide standard solution, ultrasonically homogenize the flocculent precipitate produced in the above solution or until the solution is clear, add 0.6mL of the ZIF-90 ethanol suspension sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com