Melt filter for online circulating screen cleaning of recycled plastics, with large filter screen area and implemented without material interruption

A technology for recycling plastic and super large filter screen, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of unusable, clogging, small working area of the filter screen, etc., to avoid material loss, improve cleaning efficiency, and large filter area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

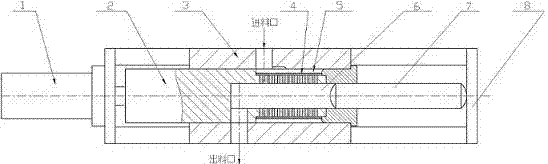

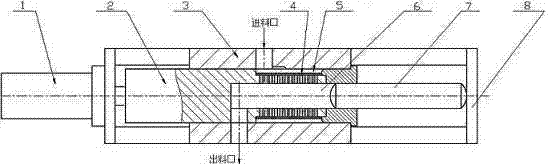

[0009] Control attached figure 1 , its structure is to include a hydraulic cylinder 1, a large plunger 2, a filter body 3, a filter screen 4, an annular columnar flow channel 5, an inner flow channel 6, a small plunger 7, and a limit plate frame 8; wherein the filter body 3 There are two or more round holes for accommodating the large plunger 2 and the inlet and outlet flow channels. The two or more large plungers are arranged in parallel and installed in the filter body in a dynamic fit. Driven by hydraulic cylinder 1 to realize axial reciprocating sliding; polygonal cylinder or cylindrical filter 4 sets are fixed on the large plunger 2, and the area of the polygonal cylinder or cylindrical filter is 4-20 times the cross-sectional area of the large plunger , the large plunger has multiple groups of radial channel holes in the section corresponding to the filter screen, and intersects with the coaxial inner flow channel of the large plunger; the small plunger 7 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com