Dealkalized wet desulfurization waste fertilizer and preparation method thereof

A technology of wet desulfurization and waste, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., to achieve the effect of increasing self-repair, avoiding secondary pollution, and ensuring fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

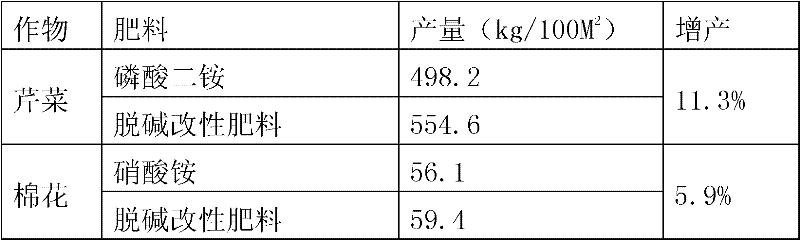

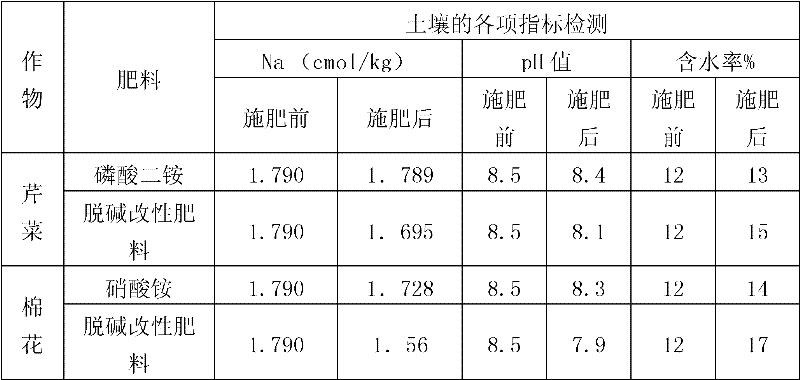

Examples

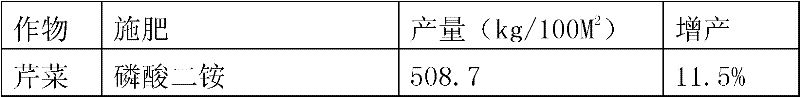

Embodiment 1

[0050] (1) Preparation of dealkalization modified fertilizer

[0051] 1. Desulfurization gypsum: The wet desulfurization waste collected from thermal power plants is naturally dried for 50 days, and the moisture content is determined to be 5.1%. After crushing, the desulfurization gypsum with a particle size of less than 200 meshes is screened.

[0052] 2. Weigh 1kg chitosan and dissolve it in 2kg industrial grade acetic acid, stir evenly to obtain acid-soluble chitosan. Among them, chitosan is prepared by chemical method, and the degree of deacetylation is more than or equal to 98%.

[0053] 3. Weigh 10 kg of diammonium phosphate, 10 kg of urea, 5 kg of ammonium sulfate, and 5 kg of ammonium nitrate, mix and pulverize them, and stir them evenly to obtain fertilizer materials.

[0054] 4. Weigh 1 kg of potassium nitrate, 1 kg of zinc acetate, and 1 kg of ferric nitrate, mix and pulverize, and stir evenly to obtain additives.

[0055]5. Weigh 40kg of desulfurized gypsum, 1kg ...

Embodiment 2

[0071] (1) Preparation of dealkalization modified fertilizer

[0072] 1. Desulfurization gypsum: The wet desulfurization waste collected from thermal power plants is naturally dried for 50 days, and the moisture content is measured to be 7%. After crushing, the desulfurization gypsum with a particle size of less than 200 meshes is screened.

[0073] 2. Weigh 2kg chitosan and dissolve it in 2kg industrial grade acetic acid, stir evenly to obtain acid-soluble chitosan. Among them, chitosan is prepared by chemical method, and the degree of deacetylation is more than or equal to 98%.

[0074] 3. Weigh 15 kg of diammonium phosphate, 20 kg of urea, 10 kg of ammonium sulfate, and 10 kg of ammonium nitrate, mix and pulverize them, and stir to obtain fertilizer materials.

[0075] 4. Weigh 0.2 kg of potassium nitrate, 2 kg of zinc acetate, and 2 kg of ferric nitrate, mix and pulverize, and stir evenly to obtain additives.

[0076] 5. Weigh 50kg of desulfurized gypsum, 2.5kg of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com