Catalyst component for vinyl polymerization and catalyst comprising the same

A technology of ethylene polymerization and catalyst, which is applied in the field of catalyst components, can solve the problem of unsatisfactory hydrogen adjustment sensitivity, etc., and achieve the effect of less subdivision content and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

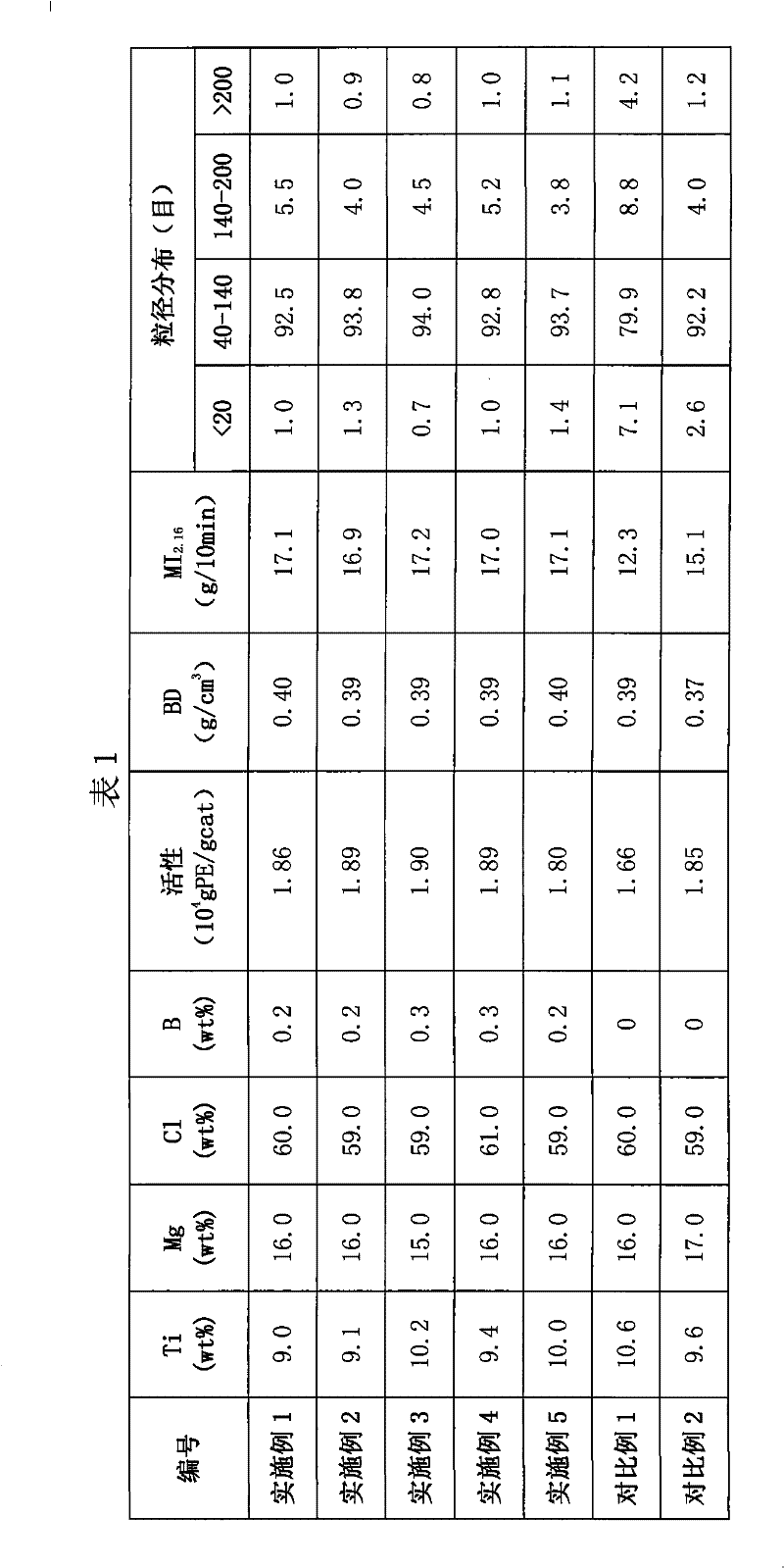

Examples

Embodiment 1

[0042] (1) Preparation of catalyst components: In a reactor fully replaced by high-purity nitrogen, 4.0g magnesium dichloride (0.042mol), 60ml toluene, 19.2g (0.084mol) tetraethoxytitanium, 6.9ml (0.1176mol) ethanol, 2.1ml (0.0126mol) triethoxyborane, heated to 70°C for reaction under stirring, and reacted at 70°C for 1 hour after the solid was completely dissolved to form a uniform solution. Cool down to 65°C, slowly add 21ml of 2M monochlorodiethylaluminum heptane solution dropwise, and maintain the reaction at 65°C for 1 hour, then raise the temperature to 90°C and continue the reaction for 1 hour. Cool the system to 30°C, let the solid precipitate, filter the filtrate, and wash the solid twice with 60ml hexane, add 60ml hexane to the solid and stir, slowly add 60ml titanium tetrachloride dropwise, and react at 30°C for 1 hour. Stirring was stopped, and the suspension was left to stand, the suspension was quickly separated into layers, the upper clear layer was removed, was...

Embodiment 2

[0046] (1) The synthesis of catalyst is the same as in Example 1. Only the amount of ethanol was changed from 6.9ml to 4.9ml.

[0047] (2) Ethylene polymerization is with embodiment 1. The catalyst composition and polymerization results are shown in Table 1.

Embodiment 3

[0049] (1) The synthesis of catalyst is the same as in Example 2. Just change diethylaluminum chloride to isobutylaluminum dichloride.

[0050] (2) Ethylene polymerization is with embodiment 1. The catalyst composition and polymerization results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com