Hydraulic control of a dual clutch transmission

A hydraulic controller, dual clutch technology, applied in clutch, transmission control, components with teeth, etc., can solve the problem of safe operation of transmission, and achieve the effect of reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

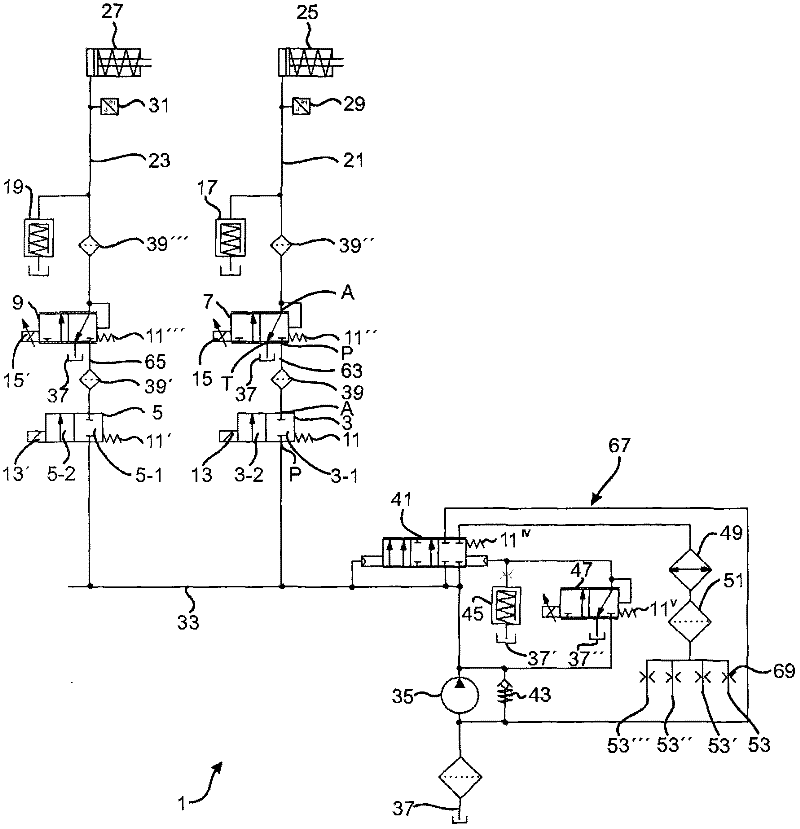

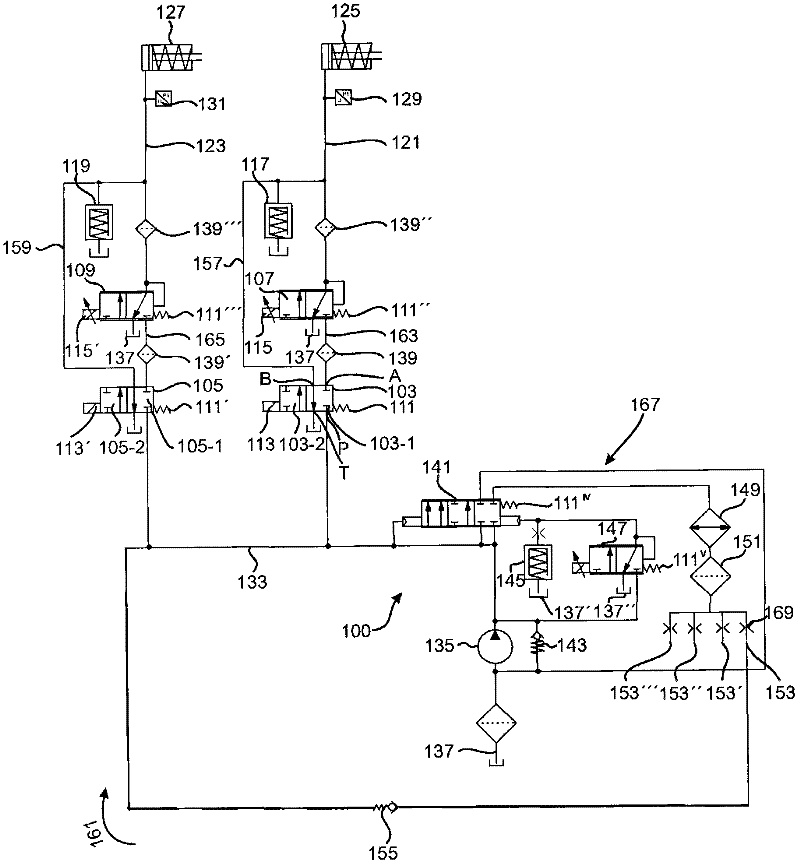

[0152] figure 1 and figure 2 An excerpt of the hydraulic system of a dual clutch transmission is shown. figure 2 Shown is a hydraulic controller 100 similar to figure 1 Hydraulic controller 1 shown in , which will be discussed below.

[0153] figure 1 The hydraulic controller 1 shown is composed of various components such as the hydraulic oil preparation circuit 67 and the controllers of the clutches 25 , 27 . The pressure supply line 33 can be regarded as the central line of the hydraulic controller. The centrally arranged pressure supply line 33 supplies hydraulic medium to subsequent lines, for example branch-shaped subsequent lines which ensure the supply of hydraulic oil to the clutches 25 , 27 . Various loads, such as clutches 25, 27, can be separated via valves 3, 5, for example, can be deactivated. The valve 3 has a first state 3-1 and a second state 3-2, the spring force of the spring 11 makes the preferential first state 3-1 hold time and the time when the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com