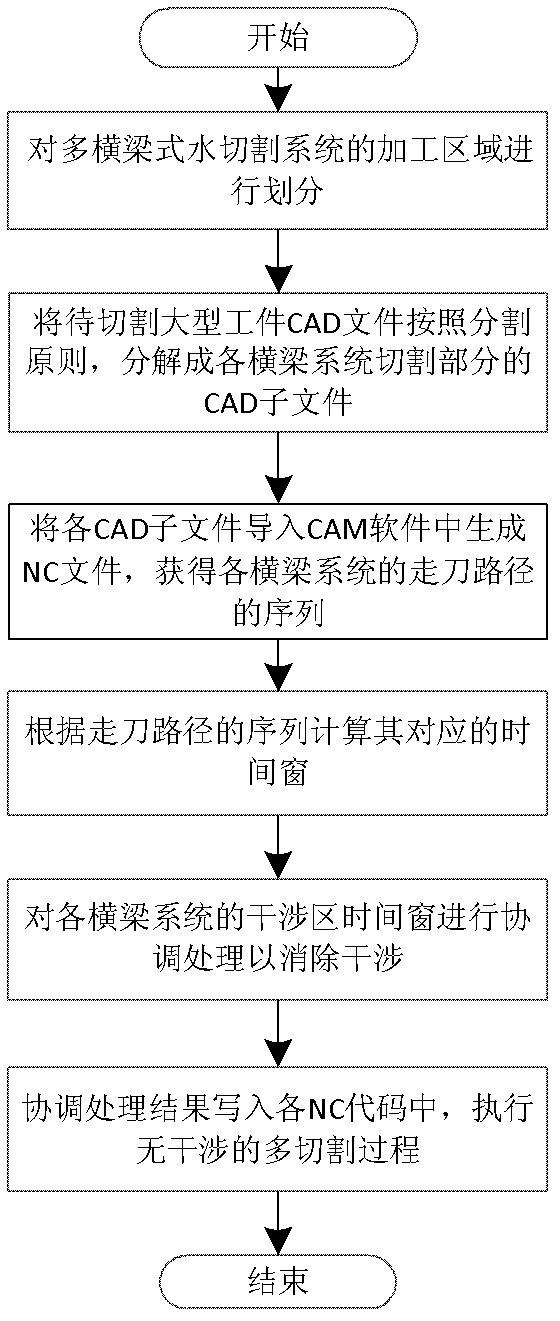

Cutting process offline coordination method of multi-beam type water jet cutting system

The technology of a cutting system and a coordination method is applied in the field of offline coordination of a multi-beam type water jet cutting system, and can solve the problems of mutual interference between adjacent cutting processes and overlapping of processing tasks of the beam system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The above and other objects, features and advantages of the present invention will be clearer through the following detailed description of the specific implementation of the present invention.

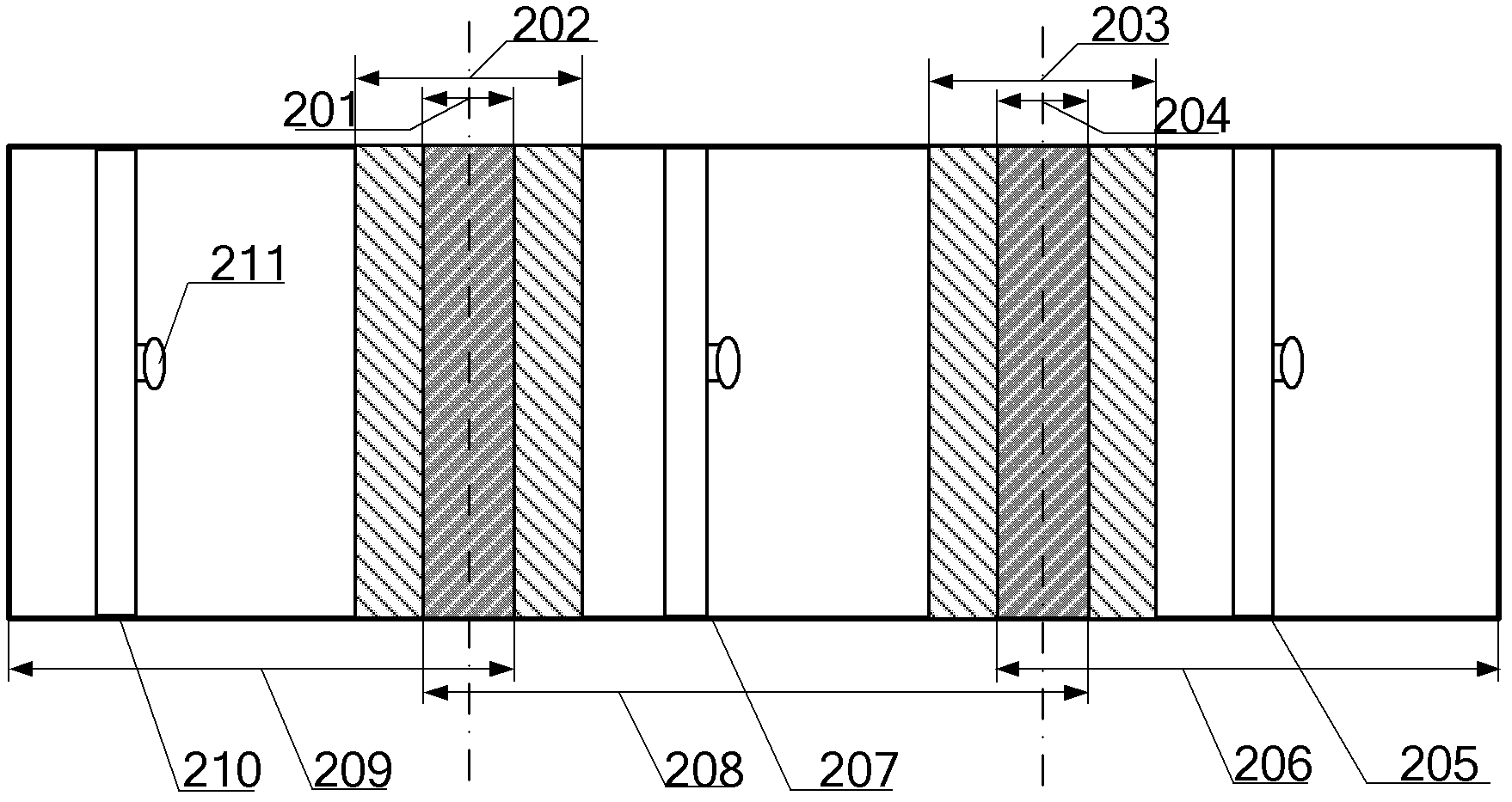

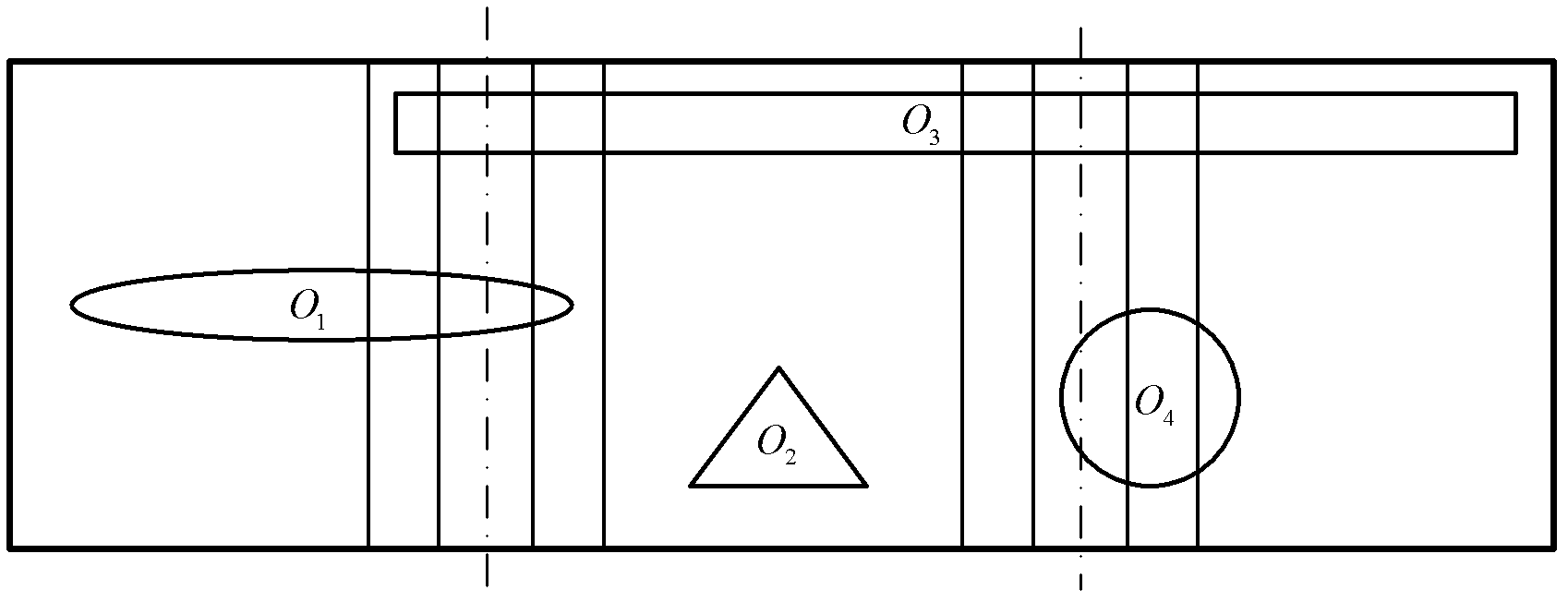

[0058] The off-line coordination method of the cutting process of the multi-beam water jet cutting system mentioned in the present invention, the multi-beam water jet cutting system includes the first beam system, the second beam system, ... , the nth beam system, n is the total number of beam systems in the multi-beam water jet cutting system, n∈□ + And n≥2, □ + It is a set of positive integers, and the beam system includes a beam equipped with a water jet head and a computer numerical control CNC system, and also includes a cutting table and a long guide rail. This multi-beam water jet cutting system can be used to cut large workpieces, the length of which is generally not less than 3 meters, such as aircraft wings, ship decks, etc.

[0059] Such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com