Bearingless switched reluctance generator

A switched reluctance, generator technology, applied in electrical components, holding devices with magnetic attraction or thrust, etc., can solve problems such as low power density of power generation, improve suspension performance, enhance radial load capacity, and facilitate modeling and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

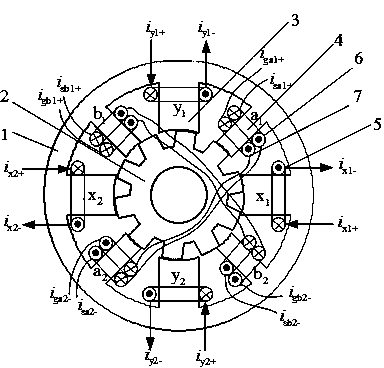

[0028] Such as figure 1 As shown, the structure diagram of the magnetic levitation switched reluctance generator of the present invention adopts a double salient pole structure of 8 / 10 poles, including a stator core 1, a rotor core 2, a levitation pole 3, a generator pole 4, a levitation winding 5, an excitation The winding 6 and the generating winding 7, the floating pole 3 and the generating pole 4 are arranged on the stator core 1 at equal intervals, and the floating pole 3 and the stator pole are wide , generator pole 4 stator pole width , rotor pole width . Independent levitation windings 5 are respectively wound on the four levitation poles 3 , and the required levitation force is obtained by individually controlling the magnitude of the current of each levitation winding 5 . The directional levitation force is determined by the current of the levitation winding 5 and control when When turned on, the resulting Suspension force in the positive direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com