Non-round section thin-wall vacuum pipeline and non-round section thin-wall vacuum chamber

A technology of vacuum pipes and vacuum chambers, applied in the field of electric vacuum, can solve the problems of difficulty in roundness control of large-diameter thin-walled stainless steel pipes, increased manufacturing and operating costs of accelerators, and increase of useless space for pipes with circular cross-sections, etc. The effect of lowering, lowering the cost and lowering the construction cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

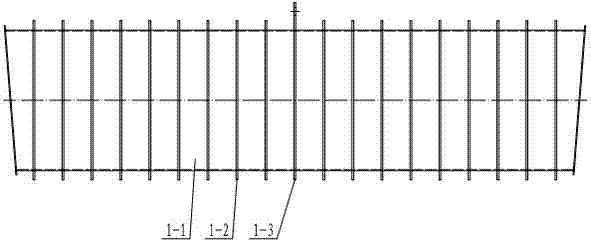

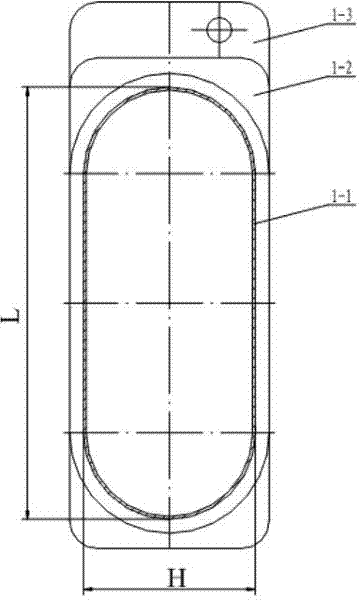

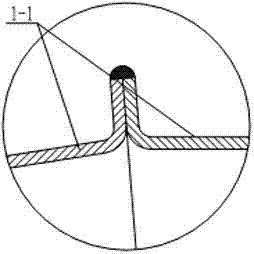

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a thin-walled vacuum pipeline with a non-circular section, the section of the tube wall of the vacuum pipeline 1-1 close to the magnetic pole of the electromagnet is a straight line, and the tube walls on both sides of the tube wall with a straight line section are semicircular arc lines, and the entire vacuum pipeline The cross-section of the vacuum pipeline 1-1 is racetrack-shaped; the tube height of the vacuum pipeline 1-1 is 62 mm, the tube width is 153 mm, and the tube wall thickness is 1 mm. The outer surface of the vacuum pipeline 1-1 is provided with reinforcing ribs 1-2 and fixed reinforcing ribs 1-3, the setting interval of the reinforcing ribs 1-2 is 32mm, and the setting of the fixed reinforcing ribs 1-3 The interval is 638mm, and the thickness of reinforcing ribs 1-2 and fixed reinforcing ribs 1-3 is 2mm. The end section of the vacuum pipeline 1-1 is curled, that is, as can be seen in the figure,...

Embodiment 2

[0025] Embodiment 2: Same as Embodiment 1, except that the vacuum pipeline 1-1 has a tube height of 10 mm, a tube width of 10 mm, and a tube wall thickness of 0.3 mm.

Embodiment 3

[0026] Embodiment 3: same as Embodiment 1, except that the vacuum pipeline 1-1 has a tube height of 90 mm, a tube width of 250 mm, and a tube wall thickness of 0.8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com